Oxidant for dyeing of sulfide dye

A technology of sulfur dyes and oxidants, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of personal and environmental damage, poor wet fastness of dyeing, peroxidation or oxidation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

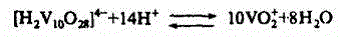

Method used

Image

Examples

Embodiment 1

[0018] In parts by weight, 50 parts of sodium chlorate, 2 parts of ammonium vanadate or sodium vanadate, 10 parts of sodium chloride, and the balance of water.

Embodiment 2

[0020] In parts by weight, 30 parts of sodium chlorate, 4 parts of ammonium vanadate or sodium vanadate, 30 parts of sodium chloride, and the balance of water.

Embodiment 3

[0022] In parts by weight, sodium chlorate is 10, ammonium vanadate or sodium vanadate is 5, sodium chloride is 15, and the balance is water.

[0023] Example 4.

[0024] In parts by weight, 60 parts of sodium chlorate, 0.5 parts of ammonium vanadate or sodium vanadate, 5 parts of sodium chloride, and the balance of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com