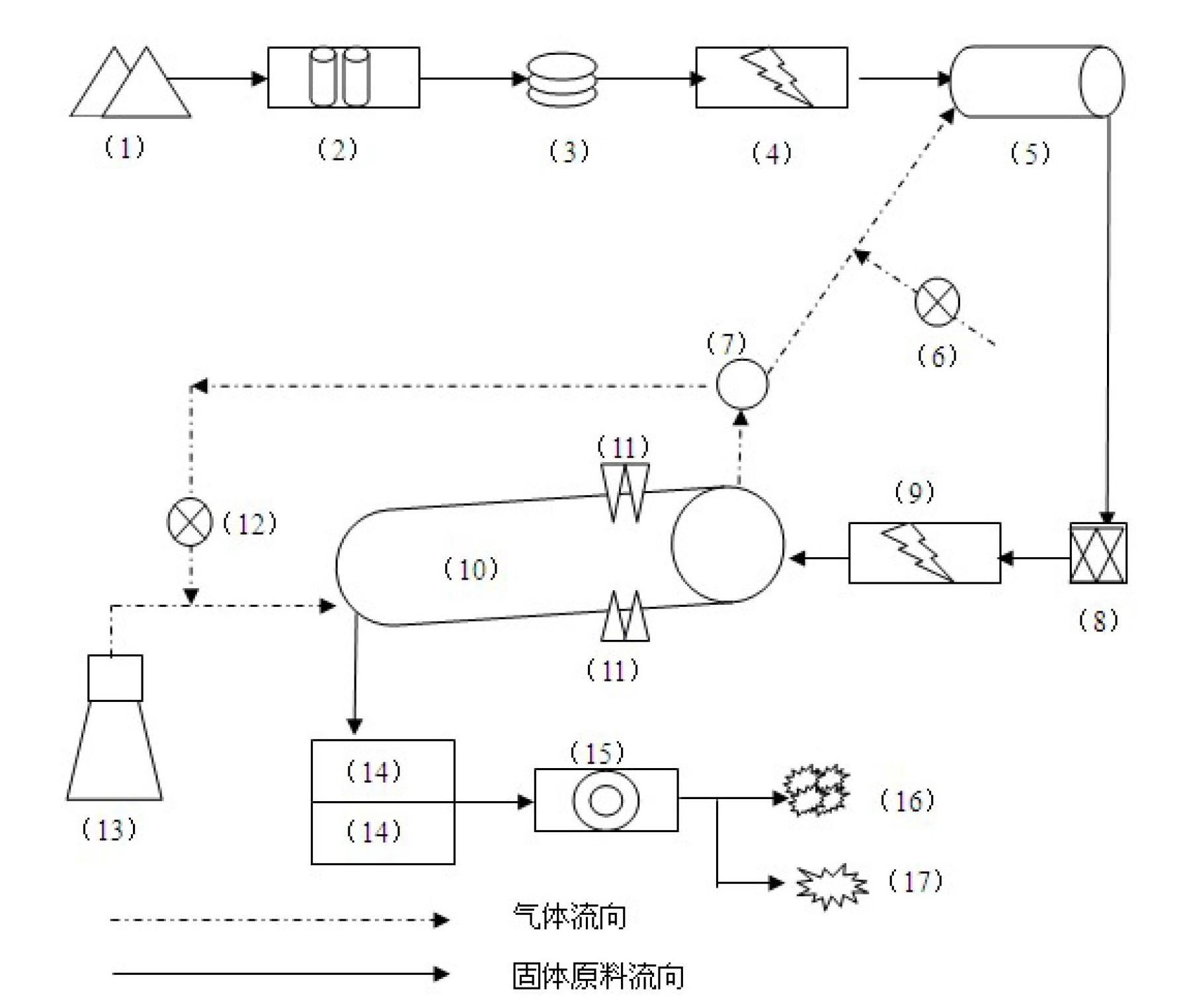

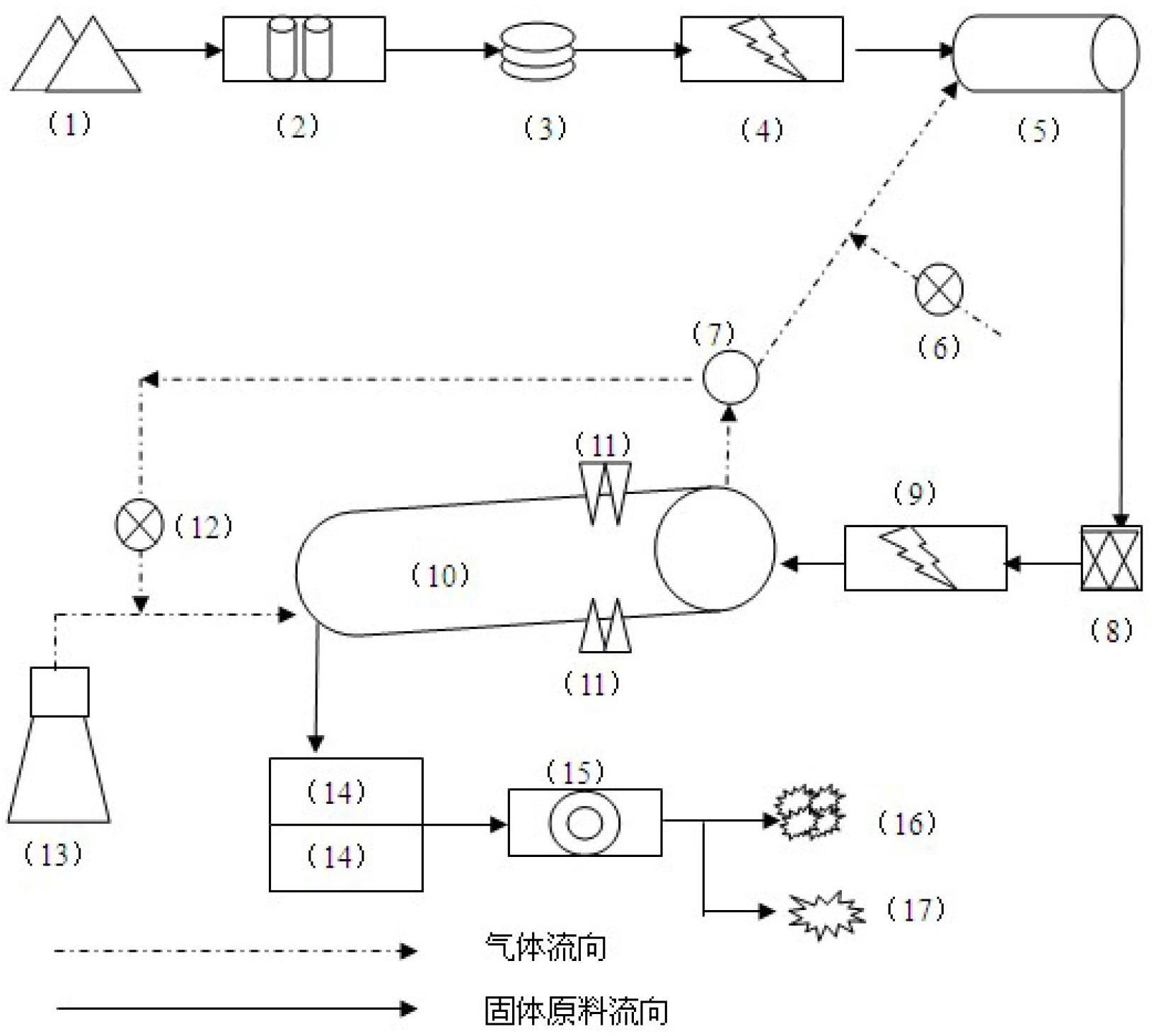

Method for preparing high purity iron ore by reducing and magnetizing red mud in rotary kiln

A magnetization treatment, rotary kiln technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high energy consumption, difficult continuous reduction reaction process, poor reaction kinetics, etc., to achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Filter and dehydrate the obtained red mud slurry through a filter press to obtain a relatively dry press cake, and then place the press cake in a drying drum, and the hot air used for drying the drum comes from the exhaust gas at the tail of the rotary kiln , the temperature of the exhaust gas is 900°C. After mixing the exhaust gas out of the rotary kiln with an equal volume of air, a medium-high temperature hot air of 400°C can be obtained. Using the medium-high temperature hot air of 400°C, the moisture content of the red mud cake in the drying drum is reduced to 3%. , get red mud block;

[0024] (2) Break the red mud lumps discharged from the drying drum into small pieces of ≤10mm, and then feed the red mud lumps of ≤10mm into the rotary kiln through the feeder. The temperature of the red mud lumps rises to 700°C, The composition of the feed temperature at 550°C is N 2 At 65%, H 2 O≤10%, CO% / (CO%+CO 2 %) In the mixture of 25% blast furnace gas and kiln exhaust...

Embodiment 2

[0027] (1) Place the obtained red mud in the drying drum. The hot air used for drying the drum comes from the waste gas at the tail of the rotary kiln. ℃ medium-high temperature hot air, use 450 ℃ medium-high temperature hot air to reduce the moisture content of the red mud cake in the drying drum to below 2%;

[0028] (2) Break the red mud lumps discharged from the drying drum into small pieces of ≤10mm, and then feed the red mud lumps of ≤10mm into the rotary kiln through the feeder. The temperature of the red mud lumps rises to 800°C, The inlet temperature is 650°C, and the composition requires N 2 At 60%, H 2 O≤10%, CO% / (CO%+CO 2 %) In the mixed gas of 22% generator gas and kiln exhaust gas, the reduction time of the red mud block in the rotary kiln is 30min, and the reduced magnetized red mud block is obtained, and more than 95% of the Fe in the red mud 2 o 3 Reduced to Fe by mixed gas 3 o 4 ; After the exhaust gas passes through three-quarters of the length of the ...

Embodiment 3

[0031](1) Put a certain amount of red mud in the drying drum for drying and further dehydration, and the moisture is reduced to 3%. Among them, the hot air used for drying the drum comes from the exhaust gas at the end of the rotary kiln, and the temperature of the exhaust gas is 925°C. After the waste gas exiting the rotary kiln is mixed with an equal volume of air, a medium-high temperature hot air of 425°C can be obtained, and the moisture of the red mud cake in the drying drum is reduced to below 3% by using the medium-high temperature hot air of 425°C;

[0032] (2) Break the red mud lumps discharged from the drying drum into small pieces of ≤10mm, and then feed the red mud lumps of ≤10mm into the rotary kiln through the feeder. Coal gas is fed into the kiln head, and the gas is a mixture of producer gas and kiln exhaust gas. The temperature of the mixed gas is 700°C, and the composition requirements are N 2 At 55%, H 2 O≤10%, CO% / (CO%+CO 2 %) at 20%, the reduction time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com