Manufacturing method of splitting-type connecting rod

A manufacturing method and pyrolysis-type technology, applied in the field of engine parts, can solve the problems of large investment in machine tools and tools, high product rejection rate, and high energy consumption, so as to reduce investment in finishing equipment and tools, and achieve high product rejection rate. , The effect of high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

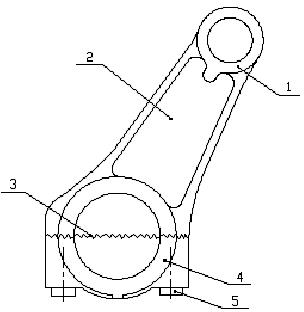

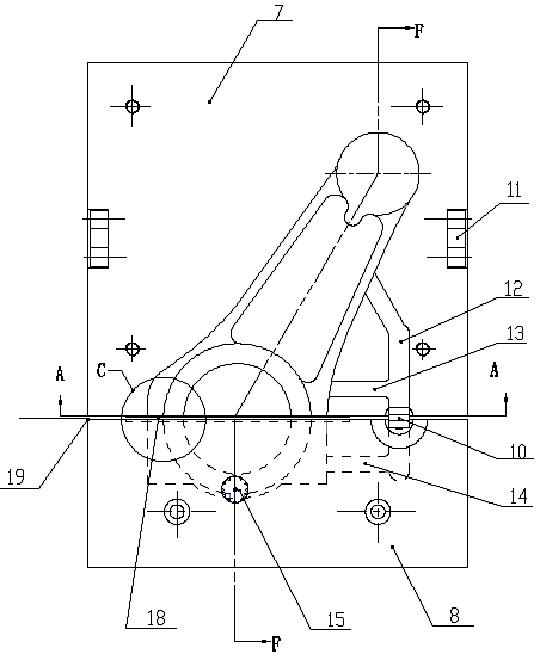

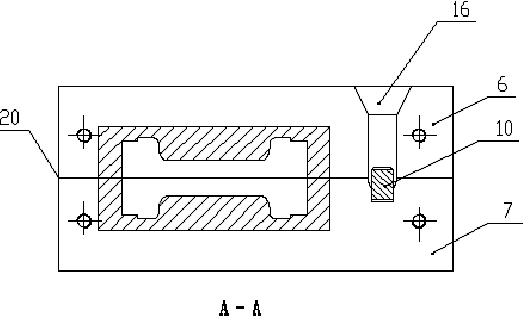

[0028] figure 1 It is the schematic diagram of the connecting rod of this embodiment. The connecting rod includes a connecting rod body 2 and a connecting rod cover 4, both of which are precisely meshed by the canine-tooth structure on the cracking surface 3, and then locked by bolts 5.

[0029] Embodiment The connecting rod is made of forged aluminum alloy LD10 with a melting point of 650 degrees Celsius. Wrought aluminum alloy belongs to aluminum-magnesium high-strength matrix aluminum alloy, which has high strength and rigidity, easy cutting and plastic processing, and can be strengthened by heat treatment. After solution treatment and artificial aging, the strength is high, and the connecting rod material can greatly reduce the weight of the product. And increase the bearing stability of the connecting rod. The cracking material is AZ31 foil, the thickness of the foil is 0.15mm, the composition of AZ30 is: w (Al) = 2.5% ~ 3.5%, w (Zn) = 0.6% ~ 1.4%, w (Si) = 0.1% , w (C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com