Preparation method of nitrogen-doped carbon material

A nitrogen-doped carbon and nitrogen technology, applied in the preparation/purification of carbon, can solve the problems of affecting performance and low nitrogen doping amount, and achieve mild reaction conditions, easily controllable nitrogen doping amount, and high nitrogen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention is a method for preparing a nitrogen-doped carbon material, the steps of which are:

[0017] (1) Take 2-5g of sucrose, add 40-80mL of ammonia water with a concentration higher than 12% to dissolve, and place it in a hydrothermal reaction kettle with a polytetrafluoroethylene lining;

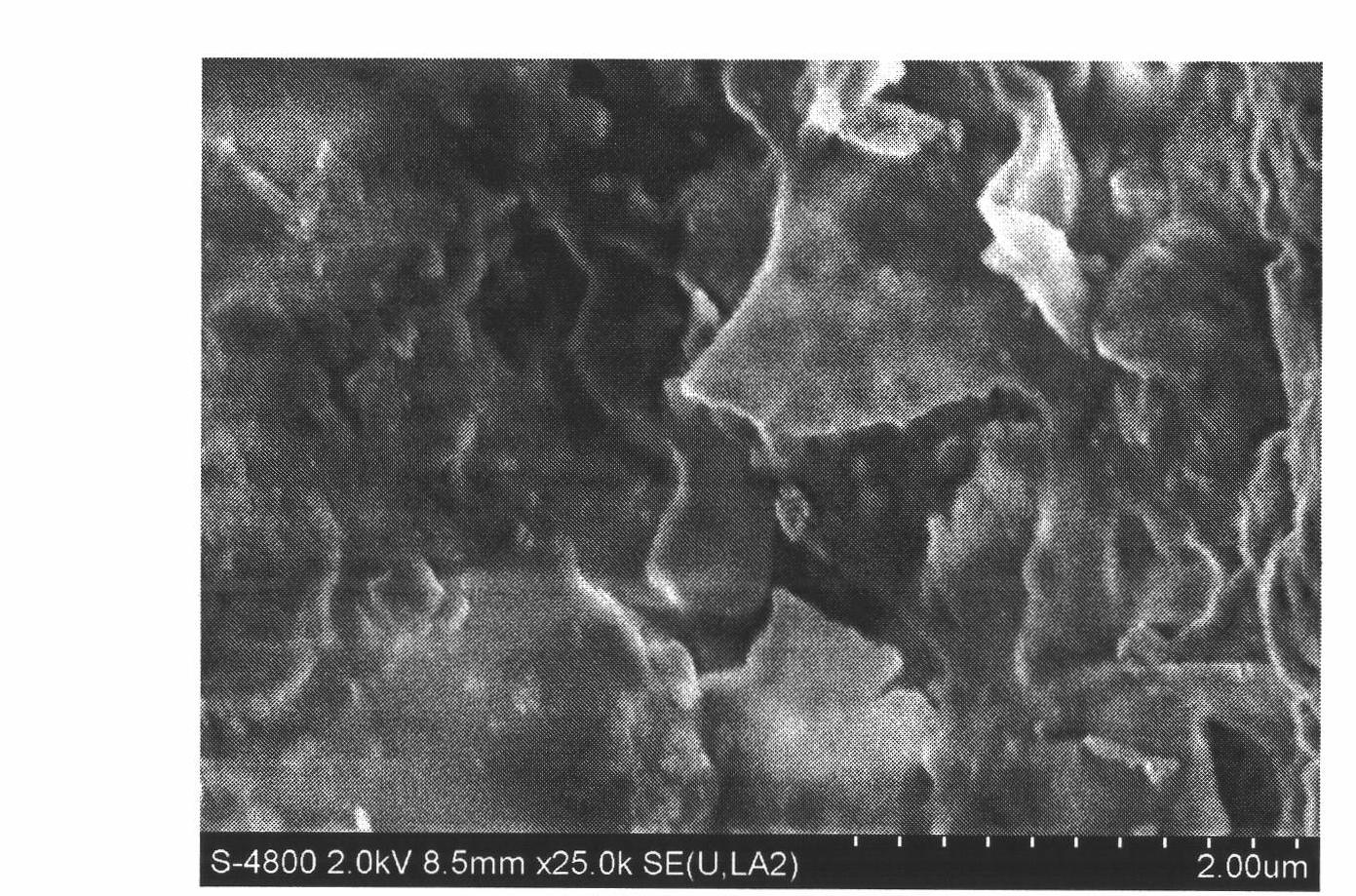

[0018] (2) heating the reaction kettle in the above (1) at a temperature of 160-200° C. for 8-24 hours, filtering after cooling, and drying in vacuum to obtain the precursor;

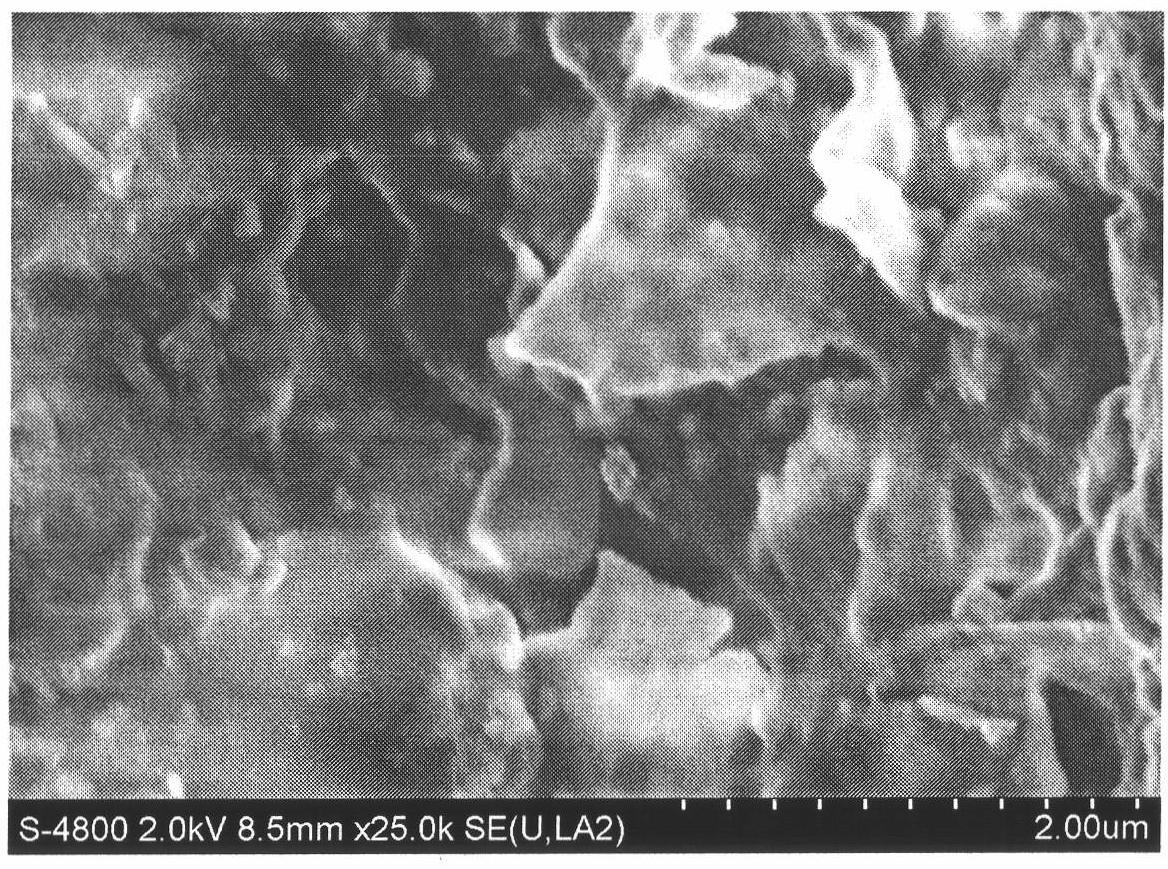

[0019] (3) heating the precursor in (2) above to 600-900°C at a rate of 5-10°C / min, and keeping it warm for 1-4 hours;

[0020] (4) Naturally cool the product in (3) above to room temperature, and grind to obtain a nitrogen-doped carbon material;

[0021] (5) The processes described in (3) and (4) above are carried out under the protection of an inert atmosphere, and the gas flow rate is 50-100 mL / min.

[0022] The inert atmosphere mentioned above is nitrogen.

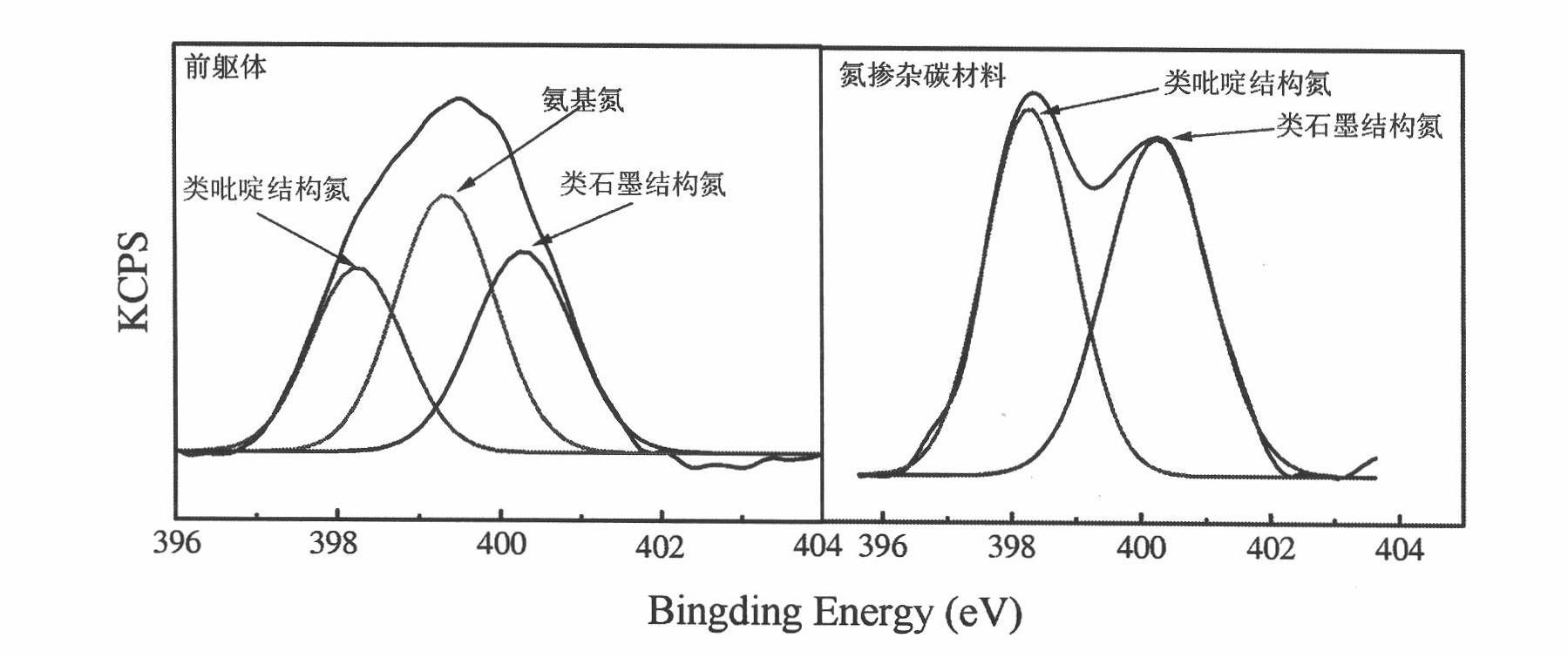

[0023] The nitrogen content of the ni...

Embodiment 2

[0027] Take 4g of sucrose, dissolve it in 60mL of 30% ammonia water, place the solution in a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 200°C for 16 hours, filter and wash to obtain a precursor with a nitrogen content of 19.6% . The precursor was heated to 800°C at a rate of 10°C / min in a nitrogen flow of 100mL / min, kept for 1 hour, cooled to room temperature under the protection of a nitrogen atmosphere, and ground to obtain a nitrogen-doped carbon material with a nitrogen content of 12.7%.

Embodiment 3

[0029] Take 3g of sucrose, dissolve it in 60mL of 24% ammonia water, put the solution in a hydrothermal reaction kettle with polytetrafluoroethylene lining, react at 200°C for 8 hours, filter and wash to obtain the precursor with a nitrogen content of 17.0% . The precursor was heated to 700°C at a rate of 5°C / min in a nitrogen flow of 60mL / min, held for 3 hours, cooled to room temperature under the protection of a nitrogen atmosphere, and ground to obtain a nitrogen-doped carbon material with a nitrogen content of 14.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com