Efficient production technology of nicotinamide

A production process, the technology of nicotinamide, applied in the field of new nicotinamide production process, can solve the problems of hidden dangers in production safety, ecological and production environment pollution, large catalyst consumption, etc., achieve good stability and repeatability, protect the ecological environment, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

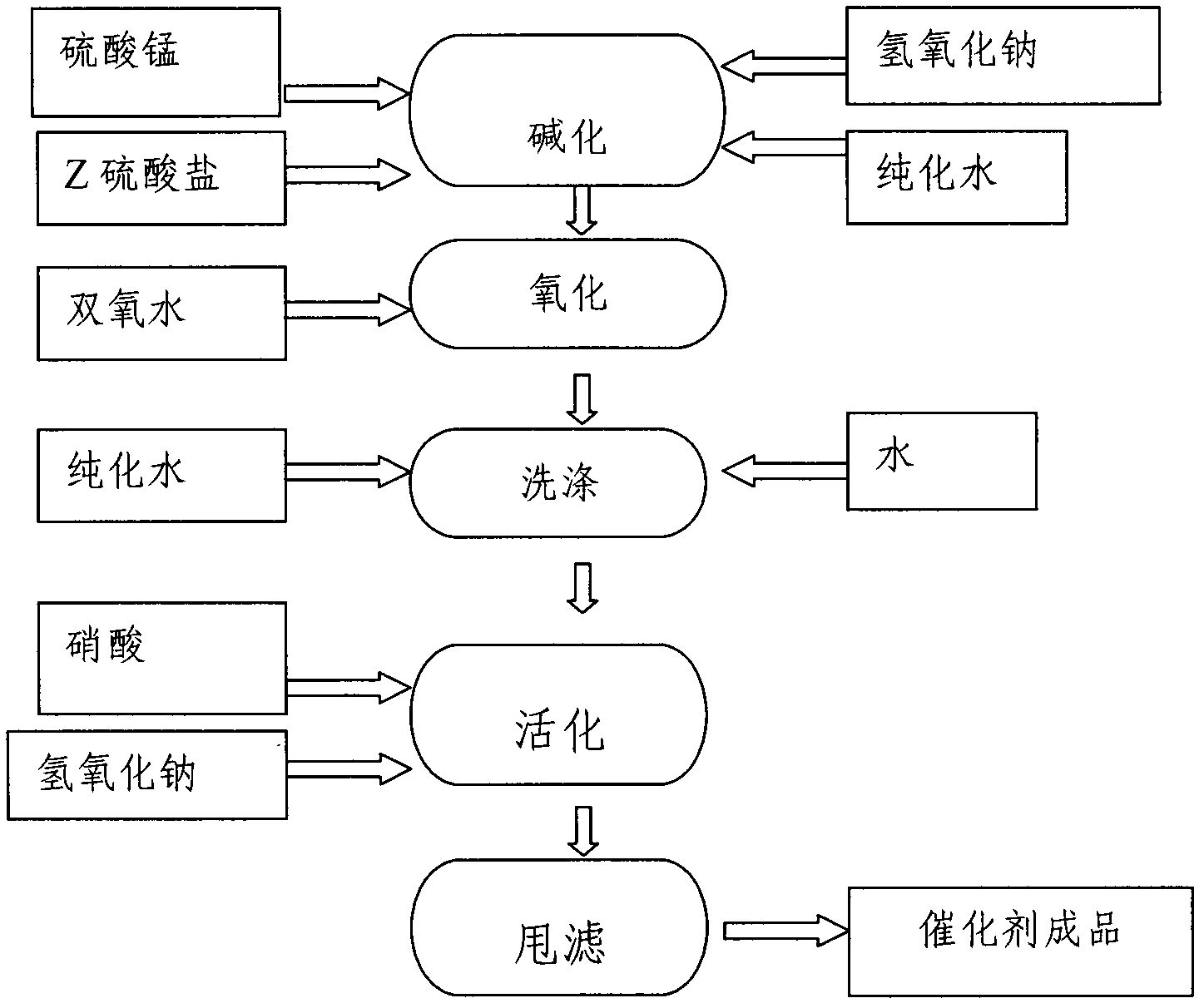

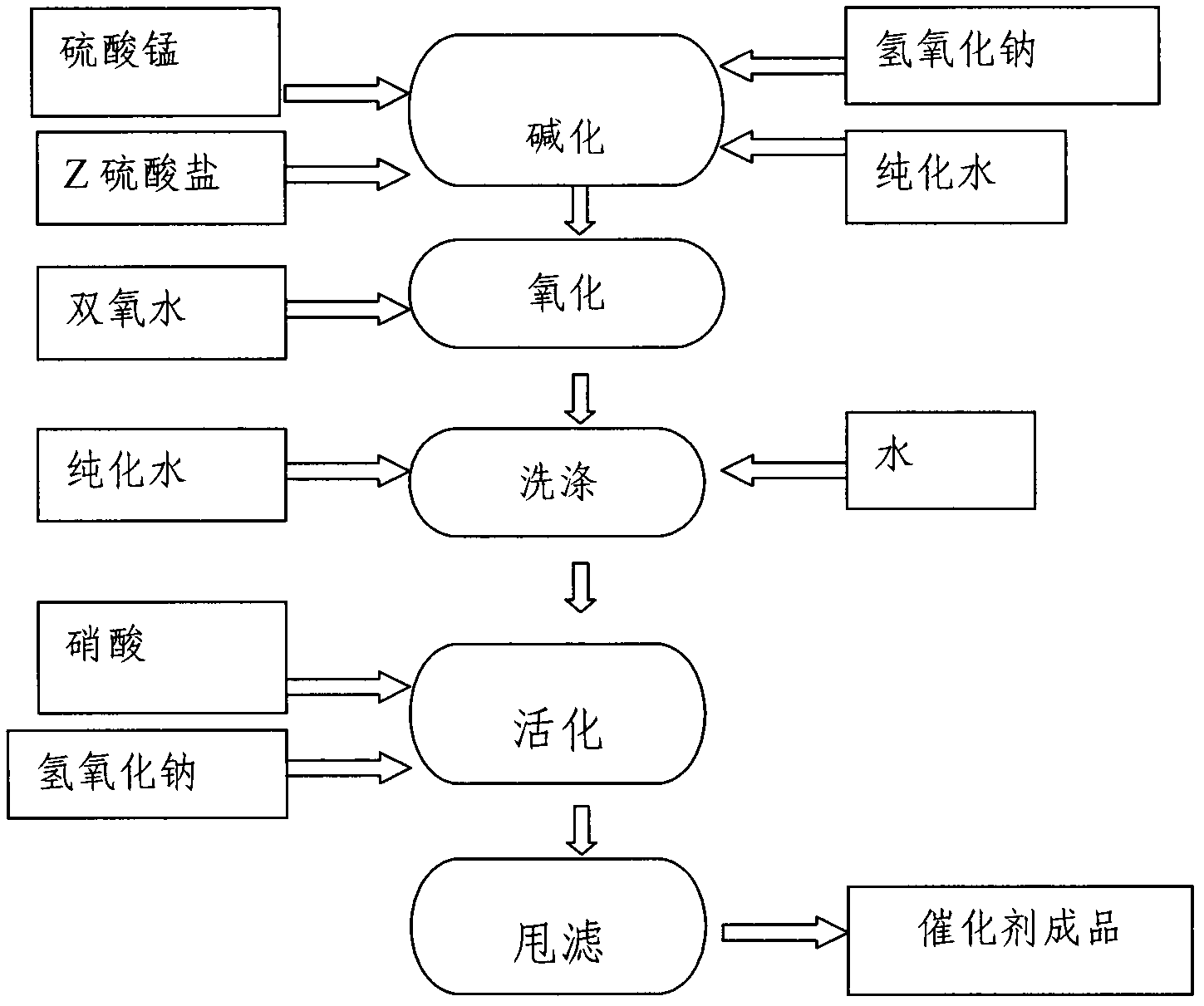

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The high-efficiency production process of nicotinamide of the present invention is carried out according to the following steps: take 0.48 mol of 3-cyanopyridine and dissolve it in 5.55 mol of water, and add 0.11 mol of double metal oxide manganese-Z catalyst, and stir the mixture at 100°C After reflux for 3 hours, the reaction solution was filtered to remove the catalyst, and the filtrate was concentrated and dried to obtain solid nicotinamide.

[0027] The following introduces the preparation of manganese-Z catalyst (Z represents the transition alkali metal)

[0028] 1. Chemical reaction formula:

[0029] MnSO 4 ·H 2 O+ZSO 4 +4NaOH+2H 2 o 2 →

[0030] MnO 2 +Z·O 2 +2Na 2 SO 4 +5H 2 o

[0031] 2. Manganese-Z catalyst preparation raw material specifications and quality requirements:

[0032] name

Specification

Quality (content)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com