Method and device for extracting polyphenol substance from Korean pine shells

A technology of Korean pine shells and Korean pine, which is applied in the field of chemical extraction of agricultural natural products, can solve the problems of low extraction rate of polyphenols and increased yield of polyphenols, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

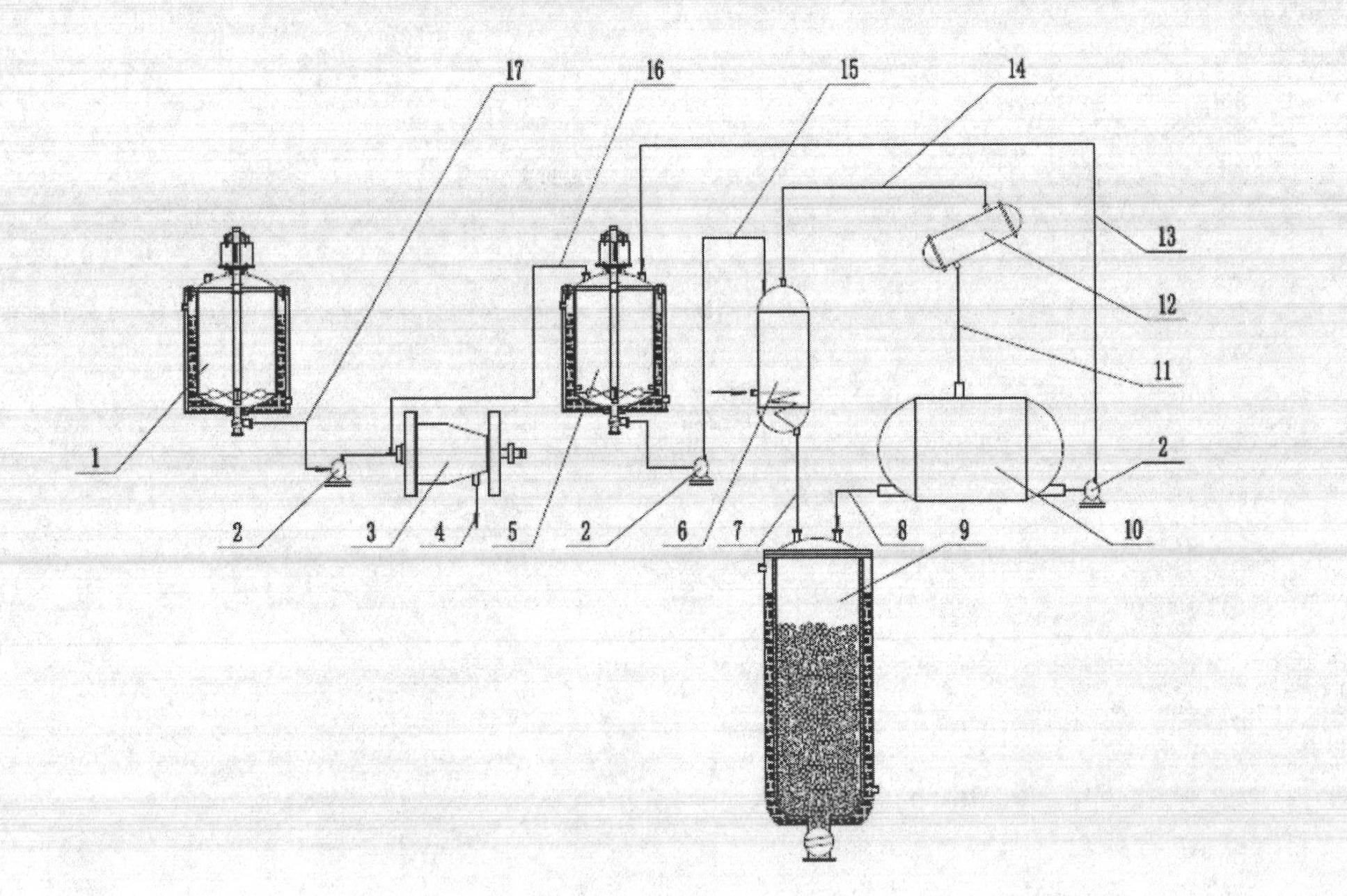

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Enzymatic hydrolysis process optimization

[0038] 1 Materials and methods

[0039] 1.1 Raw materials and reagents

[0040] Raw materials: Pine husks were collected in Yichun, Heilongjiang Province, sieved with 40 mesh after crushing, dried at low temperature to constant quality and used for later use.

[0041] Reagents: Cellulase (Sanland-chem International Inc, 30u / mg), gallic acid, Folin reagent, sodium carbonate, concentrated hydrochloric acid, sodium hydroxide, and absolute ethanol were all domestic analytical grades.

[0042] 1.2 Instruments

[0043] High-speed universal pulverizer: Tianjin Tester Instrument Company; constant temperature water bath: Beijing Medical Electronic Instrument Factory; acidity meter: Shanghai Dazhong Analytical Instrument Factory; T6 New Century UV-Vis Spectrophotometer: Beijing Puyan General Company; R-205B Rotary Evaporator: Shanghai Shensheng Instrument Company; Electronic Balance: Xi'an Xingchengzhi Instrument;

[0044] 1...

Embodiment 2

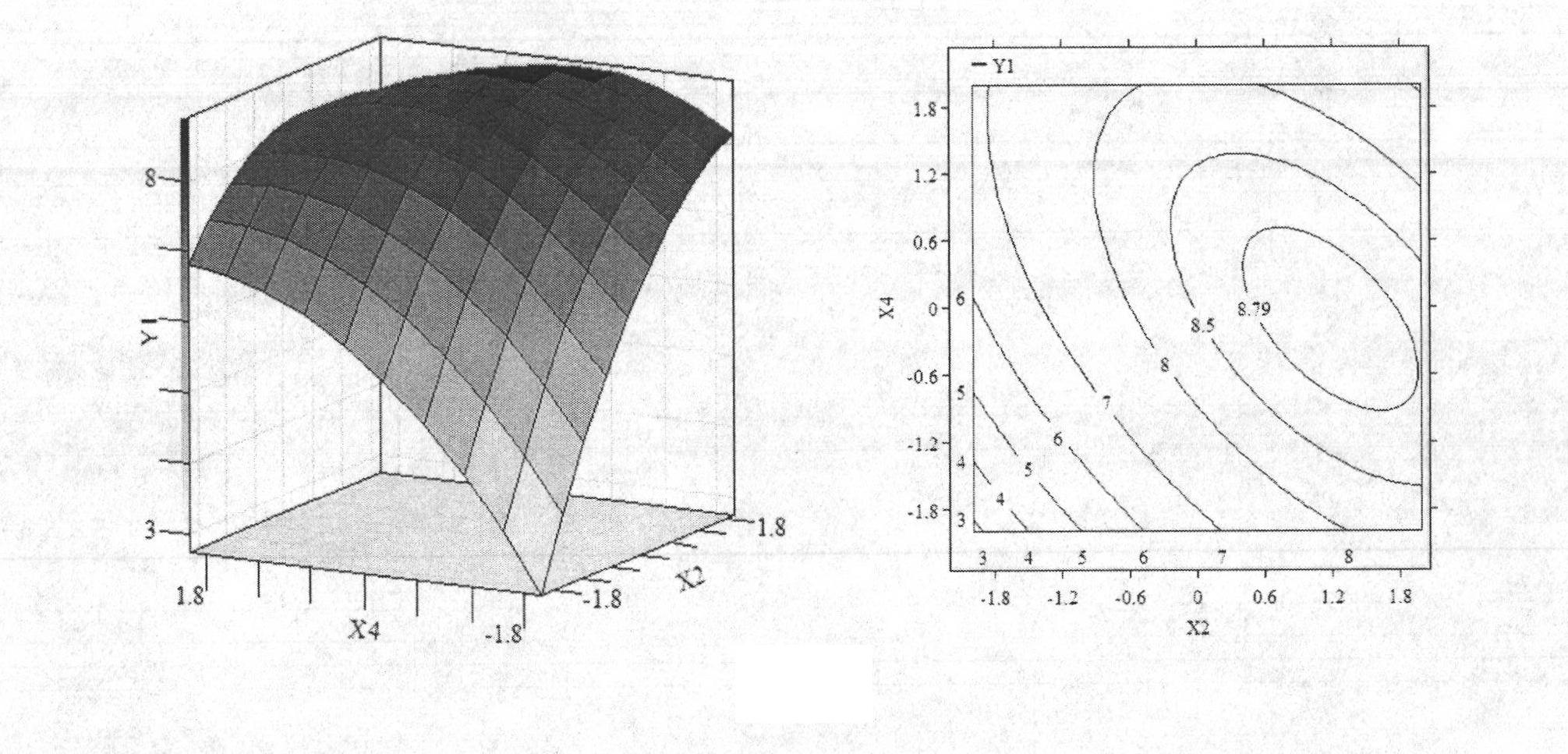

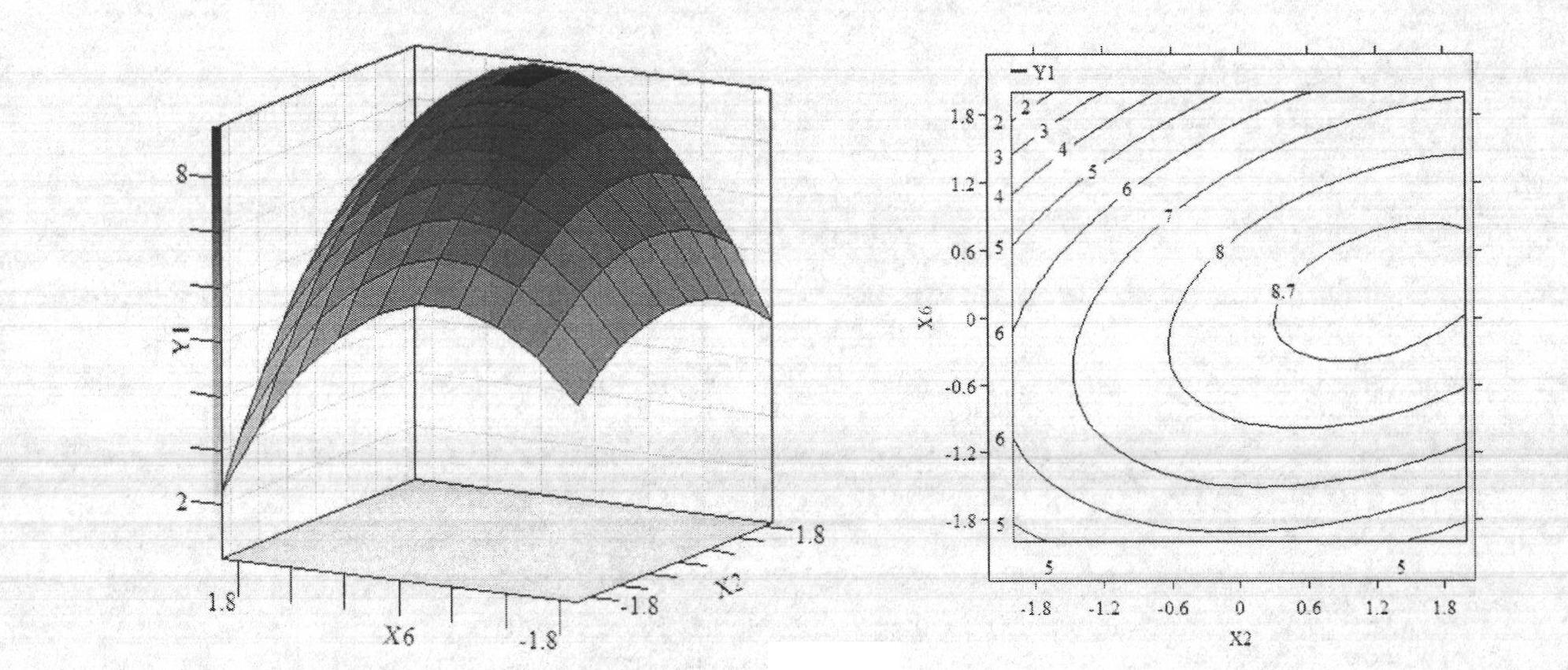

[0086] Embodiment 2 Ultrasonic extraction process optimization

[0087] 2.1 Experimental method

[0088] 2.1.1 Single factor test of polyphenol extraction from Korean pine seed husk

[0089] 2.1.1.1 Investigation of ultrasonic temperature factors

[0090] Accurately weigh 7 parts of 2.00g Korean pine seed husk powder into a 100mL beaker, add 61% ethanol as an extraction solvent, place it in an ultrasonic crusher, and press 30°C, 40°C, 50°C, 60°C, 70°C, Ultrasonic extraction was carried out at 80 °C for 2.5 h. The samples extracted under each temperature condition were collected and centrifuged immediately at 4000 rpm for 10 min. Collect the supernatant in a conical flask for testing. After the samples extracted under each temperature condition were collected completely, the polyphenol content was determined according to the Folin phenol method and the polyphenol yield was calculated.

[0091] 2.1.1.2 Investigation of ultrasonic time factor

[0092] Accurately weigh 6 par...

Embodiment 3

[0122] Through the SAS9.2 software, the optimal extraction process was obtained through the fitting analysis of the response surface optimization process results: ultrasonic extraction time 2.55h, ultrasonic temperature 62 ℃, ultrasonic power 820W. The predicted value of polyphenol extraction rate by response surface model was 8.92mg / g under this condition. For further verification, three parallel experiments were carried out using the determined optimized conditions, and the results showed that the average polyphenol extraction yield was 8.54mg / g, indicating that the experimental results were in good agreement with the model, and reached the highest yield during the experiment, indicating that the response surface The model is feasible. Example 3 Optimization of purification process for Korean pine seed shell polyphenols

[0123] 3.1 Experimental method

[0124] 3.1.1 Macroporous resin pretreatment

[0125] Soak macroporous resin AB-8 in ethanol for 24 hours, fully swell a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com