Method for treating chitin waste water

A treatment method, chitin technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. Failure to meet the national first-level discharge standards and other issues, to achieve the effect of improving nitrification and denitrification efficiency, reducing treatment costs, and improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

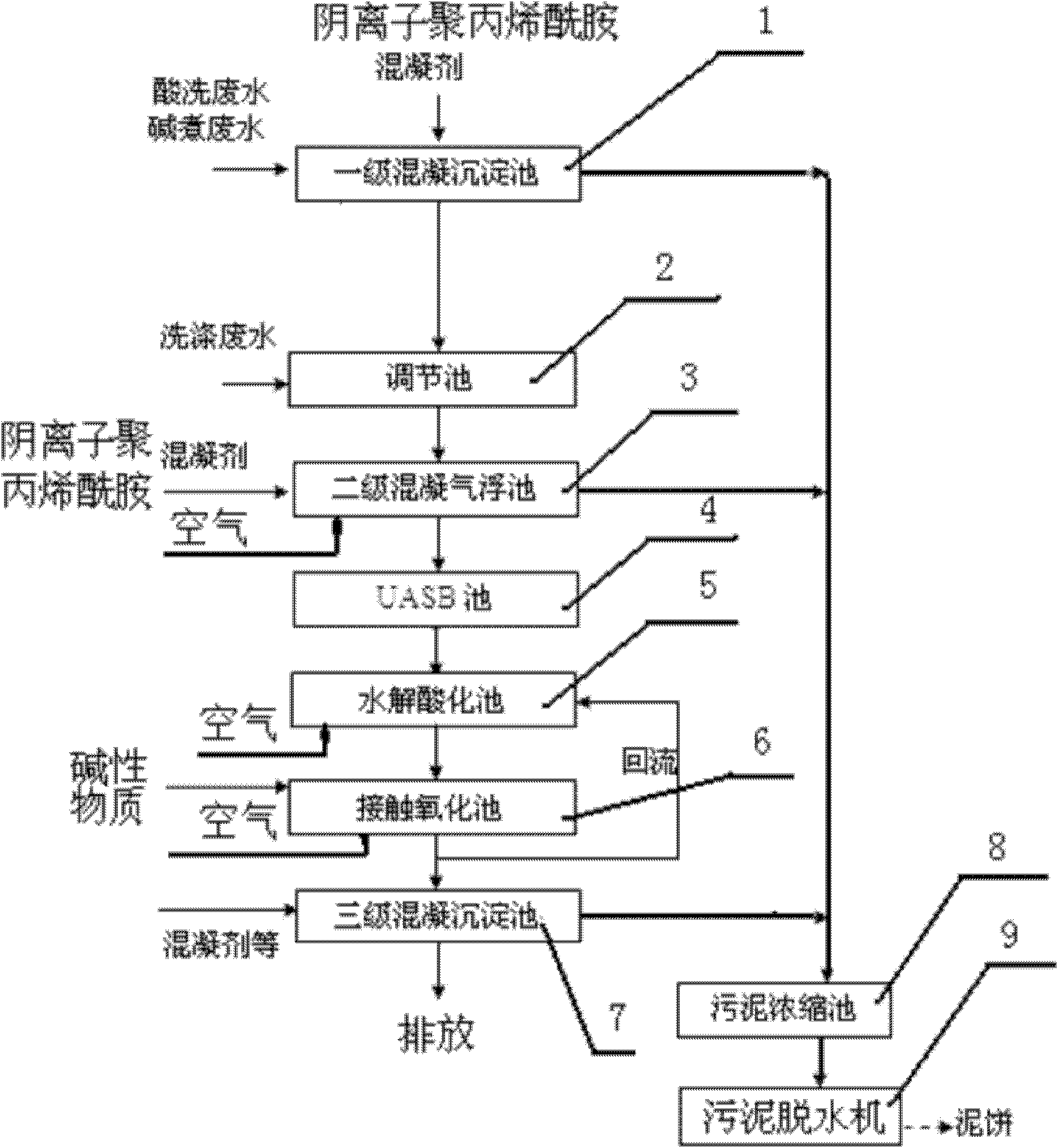

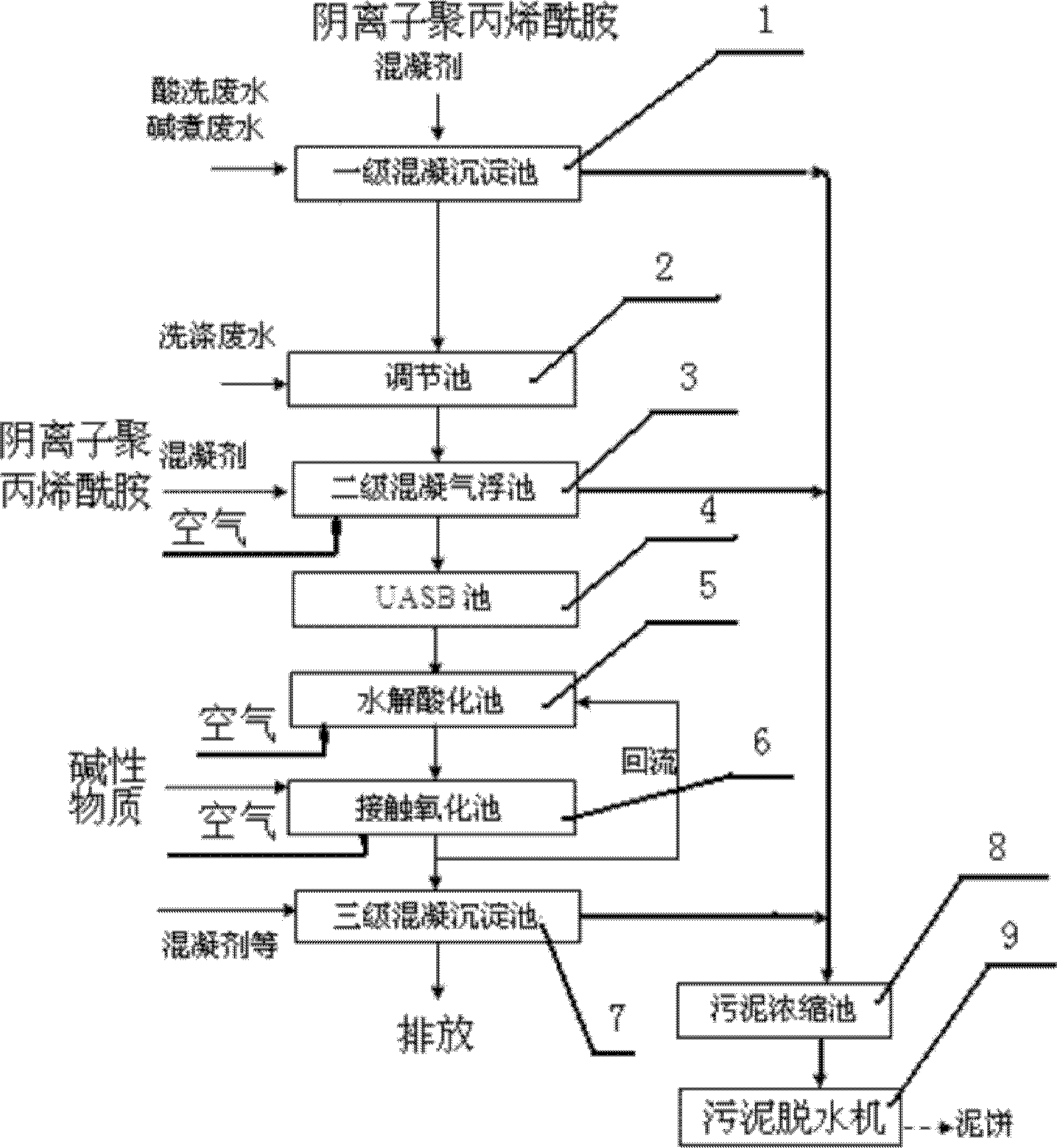

[0051] use figure 1 The process treats the wastewater generated during the production of chitin, of which:

[0052] COD of alkaline boiling water, pickling wastewater and production washing wastewater Cr Respectively 92500mg / L, 37200mg / L, 3510mg / L, ammonia nitrogen respectively 3800mg / L, 2300mg / L, 170mg / L;

[0053] Soda boiled water: washing wastewater = 1:1, volume ratio;

[0054] (1) Send alkali boiled water and pickling waste water into primary coagulation tank 1, add sodium hydroxide to adjust the pH of waste water to 8.5, add coagulant polyferric sulfate 520mg / L, anionic polyacrylamide (molecular weight 18 million ) 2.0mg / l., the coagulation reaction time is 15 minutes, and the coagulation settlement time is 3 hours;

[0055] (2) Send the effluent and washing waste water of the primary coagulation tank 1 into the regulating tank 2;

[0056] (Alkali boiled water + pickling water): washing wastewater = 1: 80, volume ratio;

[0057] (3) Send the effluent of the adjustme...

Embodiment 2

[0067] use figure 1 The process treats the wastewater generated during the production of chitin, of which:

[0068] Treatment of alkaline boiled water, pickling wastewater and washing wastewater COD Cr Respectively 64300mg / L, 27400mg / L, 2640mg / L, ammonia nitrogen respectively 4100mg / L, 1290mg / L, 136mg / L;

[0069] Soda boiled water: pickling waste water = 1: 2, volume ratio;

[0070] (1) Send alkali boiled water and pickling waste water into primary coagulation tank 1, add sodium hydroxide to adjust the pH of waste water to be 8.5, add coagulant polyaluminum ferric sulfate 430mg / L, anionic polyacrylamide (molecular weight 1800 10,000) 3.0mg / l, the coagulation reaction time is 15 minutes, the coagulation settlement time is 2 hours, and the sludge enters the sludge thickening tank 8 for sludge dehydration and reduction.

[0071] (2) Send the effluent and washing waste water of the primary coagulation tank 1 into the regulating tank 2;

[0072] (Alkali boiled water + pickling ...

Embodiment 3

[0083] Adopt the method identical with embodiment 1, wherein, the bacterial classification that step (4) adopts is Orthomonas;

[0084] Using GB11914-89 and other national standard detection methods, the results are as follows:

[0085] The effluent pH is 7.1, CODcr 80mg / l, total phosphorus 0.25mg / L, ammonia nitrogen 3.1mg / L, SS14mg / L.

[0086] The effluent is better than the Class I discharge standard of the comprehensive sewage discharge standard of the People's Republic of China "GB8978-1996".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com