Clean technique for producing nitrilotriacetic acid

A technology of nitrilotriacetic acid and trisodium nitrilotriacetate, which is applied in the field of organic chemical synthesis, can solve the problems of rare HCN raw materials, high safety protection requirements, easy condensation, etc., achieve high theoretical and use value, and the raw materials are cheap and non-toxic , The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

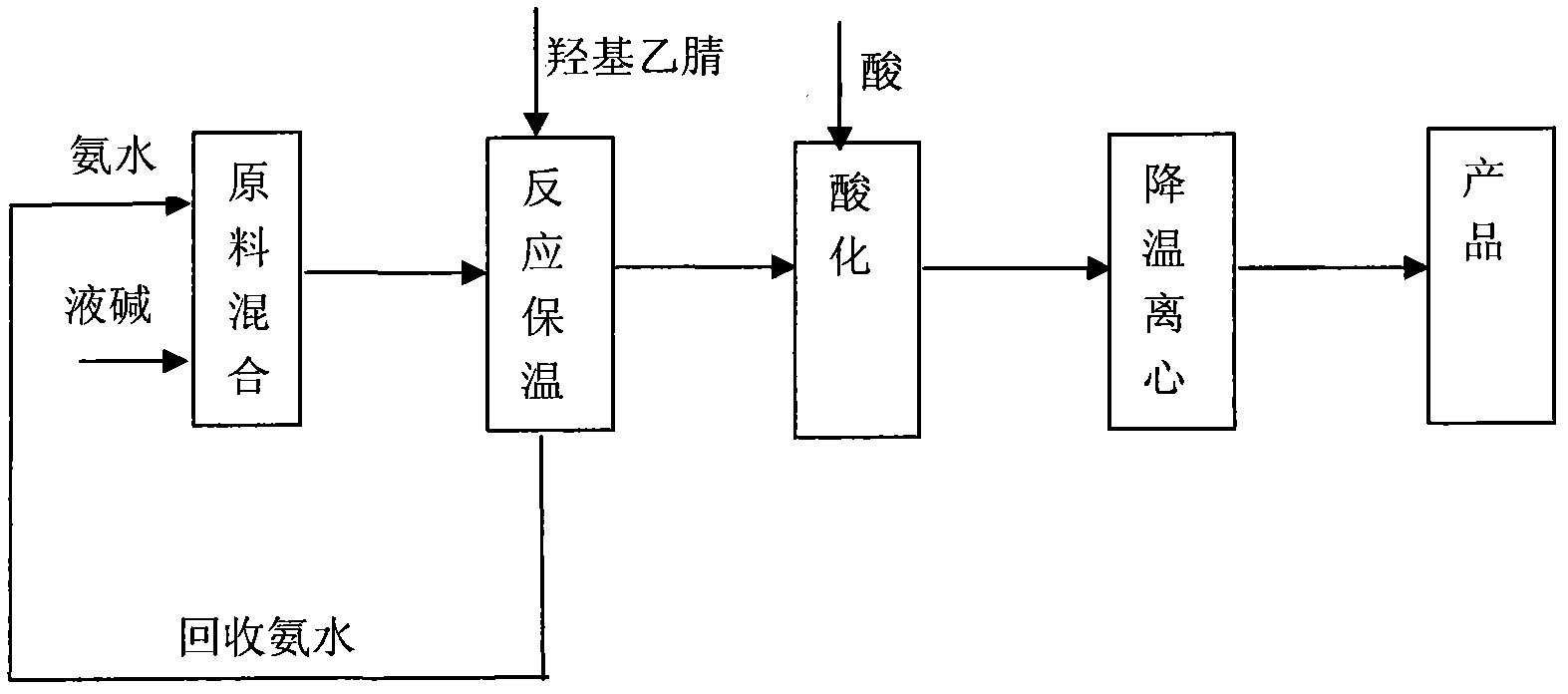

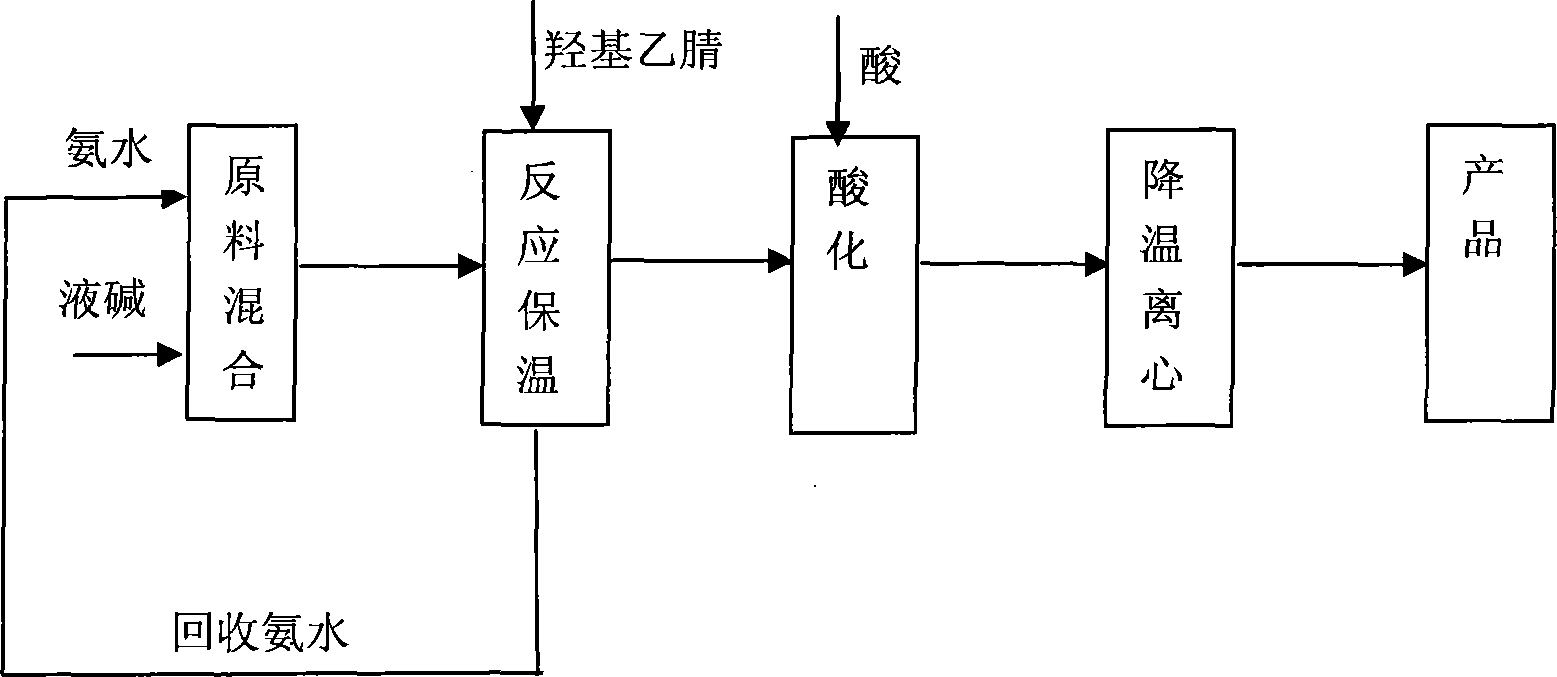

Method used

Image

Examples

Embodiment 1

[0026] Add 637Kg of 15% ammonia water to the reaction tank, inject 2560Kg of 30% sodium hydroxide solution with a pump, turn on the cooling system to cool down to 50°C, then gradually add 2115Kg of 50% hydroxyacetonitrile, and control the temperature of the reaction system at 90°C After that, add ammonia and keep it warm for 6 hours to obtain NTA-3Na feed liquid; cool down to about 60°C and neutralize with sulfuric acid to a pH of about 2.5, cool down to about 50°C, and centrifuge to obtain a product of 1052Kg, with a yield of 97.46% and a content of 99.5 %; the recovery rate of by-product ammonia water in the heat preservation process reaches 80%, which can be used as the raw material of the next batch.

Embodiment 2

[0028] Add 600Kg of 15% ammonia water to the reaction tank, inject 2120Kg of 30% sodium hydroxide solution with a pump, turn on the cooling system to cool down to 10°C after the addition, and then gradually add 1869Kg of 50% hydroxyacetonitrile to control the temperature of the reaction system at 90°C After that, add ammonia and keep it warm for 4 hours to obtain NTA-3Na feed liquid; cool down to about 60°C and neutralize with sulfuric acid to a pH of about 1.0, cool down to about 50°C, and centrifuge to obtain a product of 961Kg with a yield of 94.29% and a content of 99.2 %; The recovery rate of ammonia water by-product in the heat preservation process reaches 92% and can be used as the raw material of the next batch.

Embodiment 3

[0030] Add 800Kg of 10% ammonia water to the reaction tank, inject 2060Kg of 32% sodium hydroxide solution with a pump, turn on the cooling system to cool down to 40°C, and then gradually add 1826Kg of 50% hydroxyacetonitrile to control the temperature of the reaction system at 90°C After that, add ammonia and keep it warm for 1 hour to obtain NTA-3Na feed liquid; cool down to about 60°C and neutralize it with hydrochloric acid to a pH of about 1.5, cool down to about 50°C, and centrifuge to obtain a product of 864Kg, with a yield of 95.8% and a content of 99.8%. ; The recovery rate of the by-product ammonia water in the heat preservation process reaches 94.3%, which can be used as the raw material of the next batch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com