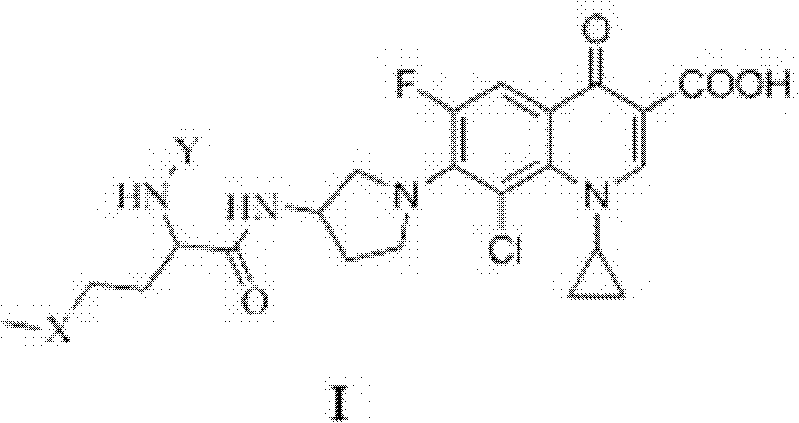

Methionine or oxidized methionine modified Clinafloxacin and application thereof

A technology for oxidizing methionine and methionine, which is applied in the fields of chemistry and pharmacy, can solve the problems of oxidation, low chemical stability, and not easy to accept, and achieves the effect of high chemical stability and meeting various needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

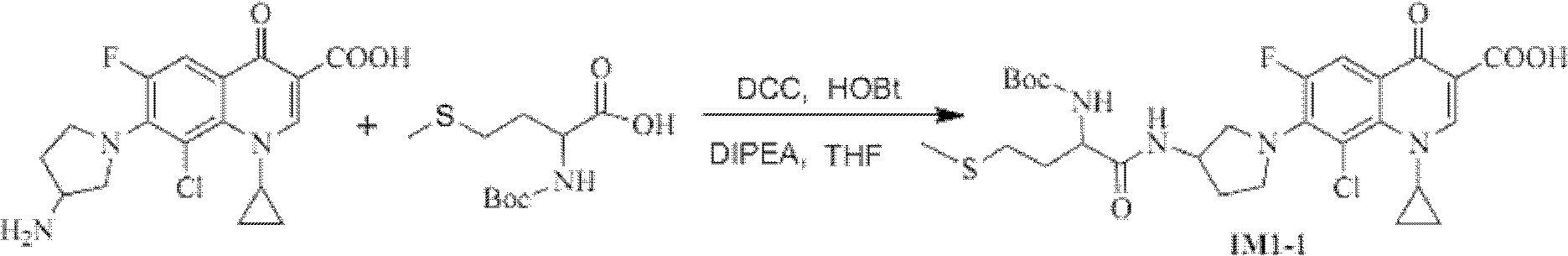

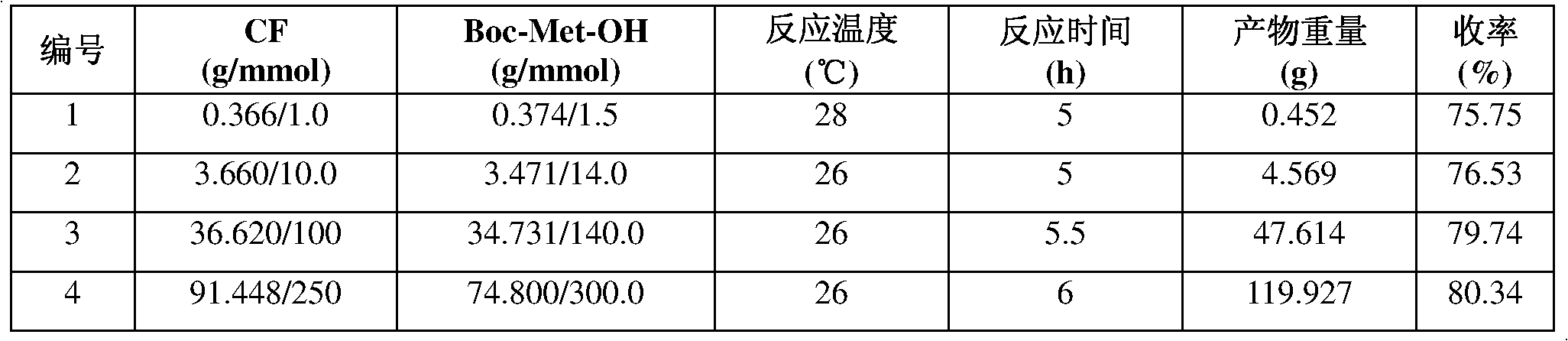

[0014] Example 1. Synthesis of compound IM1-1

[0015]

[0016] Add N-tert-butoxycarbonylmethionine (Boc-Met-OH), 1-hydroxybenzotriazole (HOBt) and an appropriate amount of tetrahydrofuran (THF) (subject to the complete dissolution of the raw materials) into the reaction flask, and stir to dissolve , Cooling in an ice bath, adding dicyclohexylcarbodiimide (DCC) and diisopropylethylenediamine (DIPEA), stirring in an ice bath for 30 minutes, adding clinfloxacin (CF) (CF, Boc-Met-OH, HOBt) The molar ratio of DCC and DIPEA is 10:12-14:12-15:12-15:15-20), and an appropriate amount of THF (subject to stirring) is added, the reaction is stirred at room temperature, and thin layer chromatography ( TLC) Monitor the progress of the reaction. After the reaction, the reaction solution was allowed to stand overnight at 4°C and filtered with suction. The filter cake was thoroughly washed with dichloromethane (DCM). The washing solution was combined with the filtrate, and the solvent was disti...

Embodiment 2

[0019] Example 2. Synthesis of compounds IM2-1 and IM2-2

[0020]

[0021] The raw material IM1-1 was added to the reaction flask, and then DCM was gradually added (subject to the complete dissolution of the raw materials), cooled in an ice bath, m-chloroperoxybenzoic acid (mCPBA) was added, and the reaction was stirred under temperature control, and the reaction progress was monitored by TLC. After the reaction is over, if a light yellow turbid liquid is obtained, add an appropriate amount of DCM to completely dissolve the solid; if a clear liquid is obtained, no additional DCM is required; then use 5% (w / w) Na 2 CO 3 Wash the solution and saturated brine, anhydrous Na 2 SO 4 Dry, filter, and distill the filtrate under reduced pressure to remove the solvent to obtain a crude product. The crude product is recrystallized with DCM-petroleum ether mixed solvent to obtain compound IM2-1 or IM2-2. Some synthetic experimental conditions and results are shown in Tables 2 to 3.

[0022] T...

Embodiment 3

[0028] Example 3. Synthesis of compounds TM1-1, TM1-2 and TM1-3

[0029]

[0030] Add raw materials IM1-1, IM2-1 or IM2-2 and appropriate amount of DCM (subject to complete dissolution of the raw materials) into the reaction flask, stir to dissolve, cool in an ice bath, slowly add TFA dropwise, stir the reaction in an ice bath, and monitor the reaction by TLC process. After the reaction, the TFA was removed as much as possible by distillation under reduced pressure. The residue was slowly added to the frozen ether, stirred, placed in the refrigerator to crystallize, the ether was aspirated, and the solid was washed with frozen ether and dried to obtain compounds TM1-1 and TM1- 2 or TM1-3. Some synthetic experimental conditions and results are shown in Tables 4-6.

[0031] Table 4 Synthesis conditions and results of compound TM1-1

[0032]

[0033] Table 5 Synthesis conditions and results of compound TM1-2

[0034]

[0035] Table 6 Synthesis conditions and results of compound TM1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com