Freeze-dried truffle slice production method

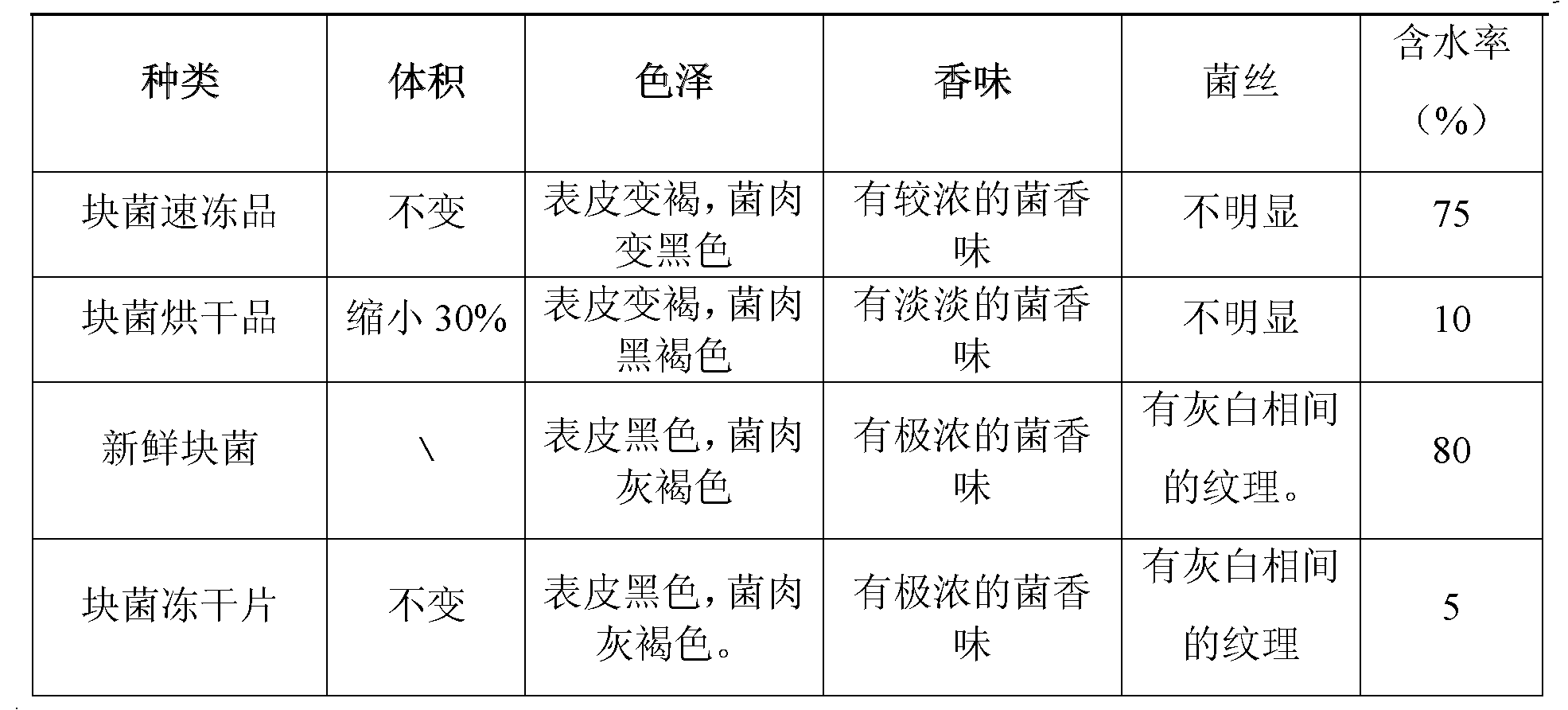

A production method and technology for freeze-dried tablets, which are applied in the field of new biological products, can solve the problems of inconvenient use, blackening, troublesome preservation and transportation of quick-frozen products, and achieve broad market prospects, long shelf life, and convenient transportation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A. Raw material processing: collect fresh truffles in the production area, wash and select truffles with a diameter of 5-8cm, slice them, soak them in edible ethanol containing 0.25% citric acid and 0.07% TBHQ by weight for 2min, and dry them at 8°C Dry surface moisture.

[0049] B. Freezing: put the raw materials processed in A into a vacuum freeze dryer for freezing, the freezing speed is 1°C / min, the final freezing temperature is -30°C, and the temperature is kept for 2 hours.

[0050] C. Vacuum drying: evacuate the vacuum freeze dryer to 30 Pa (vacuum degree), control the drying temperature at -20° C., and dry for about 5 hours.

[0051] D. Desorption drying: raise the drying temperature to 45°C (heating rate 2°C / min), gradually reduce the vacuum pressure to 8Pa, and dry for 6 minutes.

[0052] E. Packaging: Take out the dried product in time, and pack it in an aluminum foil composite bag filled with nitrogen and sealed under aseptic conditions.

[0053]F. Storage...

Embodiment 2

[0060] A. Raw material processing: collect fresh truffles in the production area, wash and select truffles with a diameter of 3-5cm, slice them, soak them in edible ethanol containing 0.35% citric acid and 0.04% TBHQ by weight for 1min, and dry them at 5°C Dry surface moisture.

[0061] B. Freezing: put the processed raw materials in A into a vacuum freeze dryer for freezing, the freezing speed is 2°C / min, the final freezing temperature is -25°C, and keep warm for 1h.

[0062] C. Vacuum drying: vacuumize the vacuum freeze dryer to 20Pa (vacuum degree), control the drying temperature at -18°C, and dry for about 3 hours.

[0063] D. Desorption drying: raise the drying temperature to 40°C (heating rate 2°C / min), gradually reduce the vacuum pressure to 5Pa, and dry for 5 minutes.

[0064] E. Packaging: Take out the dried product in time, and pack it in an aluminum foil composite bag filled with nitrogen and sealed under aseptic conditions.

[0065] F. Storage: Store in the dark ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com