Snow-melting ice-thawing method of composite mesh grid

A weaving mesh and snow-melting technology, which is applied to roads, pavement details, roads, etc., can solve the problems of poor stability and reliability of heating power, poor corrosion resistance of metal heating elements, and fluctuations in heating power, achieving fast construction, light weight, The effect of stable heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

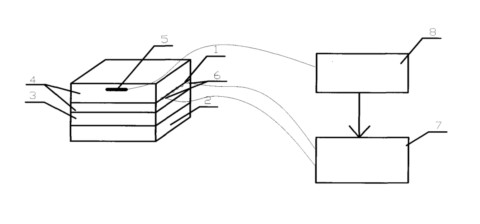

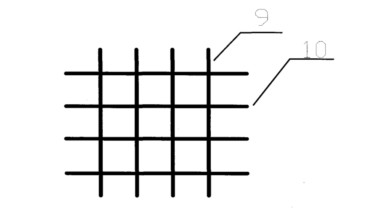

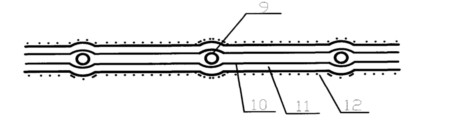

[0019] attached figure 1 An electric heating snow-melting and ice-melting automatic control system based on carbon fiber-glass fiber composite braided mesh is presented. The construction method of carbon fiber-glass fiber composite woven mesh is as follows: firstly, a heat insulation layer 3 is set on the base layer 2 of the heated body, and the thickness is controlled at 20mm to reduce the heat loss transmitted downward; Layer 4, with a thickness of about 8mm, is generally expected to have a large thermal conductivity; then the carbon fiber-glass fiber composite woven mesh 1 that has been electrically insulated and sand-bonded is spread evenly, and the warp-oriented carbon fibers in the composite woven mesh The beam heating body 9 is parallel to the short side of the body to be heated, and the electrical contacts 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com