Conductive paste for front electrode of silicon crystal solar battery

A technology for solar cells and conductive pastes, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials. , The effect of reducing contact resistance and improving contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

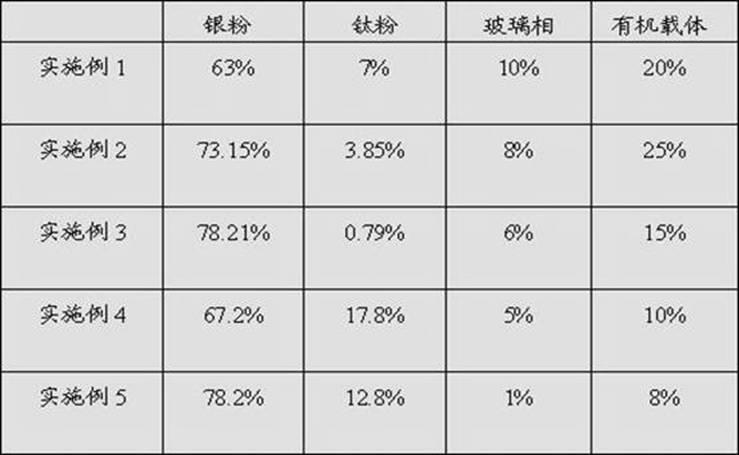

[0040] Embodiment 1-5: a kind of conductive paste for the front electrode of silicon solar cell, the raw material formula of described conductive paste is made up of the material that has following mass percentage content, see Table 1:

[0041] Table 1

[0042]

[0043] Described organic vehicle is made up of each component of following parts by weight, see table 2:

[0044] thickener solvent Thixotropic agent Surfactant Plasticizer coupling agent Example 1 0.2 6 0.3 0.15 0.8 0.08 Example 2 0.6 7.2 0.5 0.05 1.5 0.15 Example 3 1 8.5 0.85 0.5 0.3 0.1 Example 4 0.8 9.2 0.8 0.25 2 0.05 Example 5 0.5 9 1 0.3 1 0.2

[0045] The thickener of embodiment 1 is ethyl cellulose; The thickener of embodiment 2 is ethyl cellulose hydroxymethyl cellulose; The thickener of embodiment 3 is ethyl cellulose hydroxyethyl cellulose; Implement The thickener of example 4 is ethyl cellulose rosin; The thickener of emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com