Catalyst carrier or catalyst, and process for production thereof

A catalyst carrier and catalyst technology, which is applied in the direction of catalyst activation/preparation, catalyst protection, chemical instruments and methods, etc., can solve the problems of small exhaust gas volume and poor purification performance, and achieve the effect of improving heat resistance and NOx purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

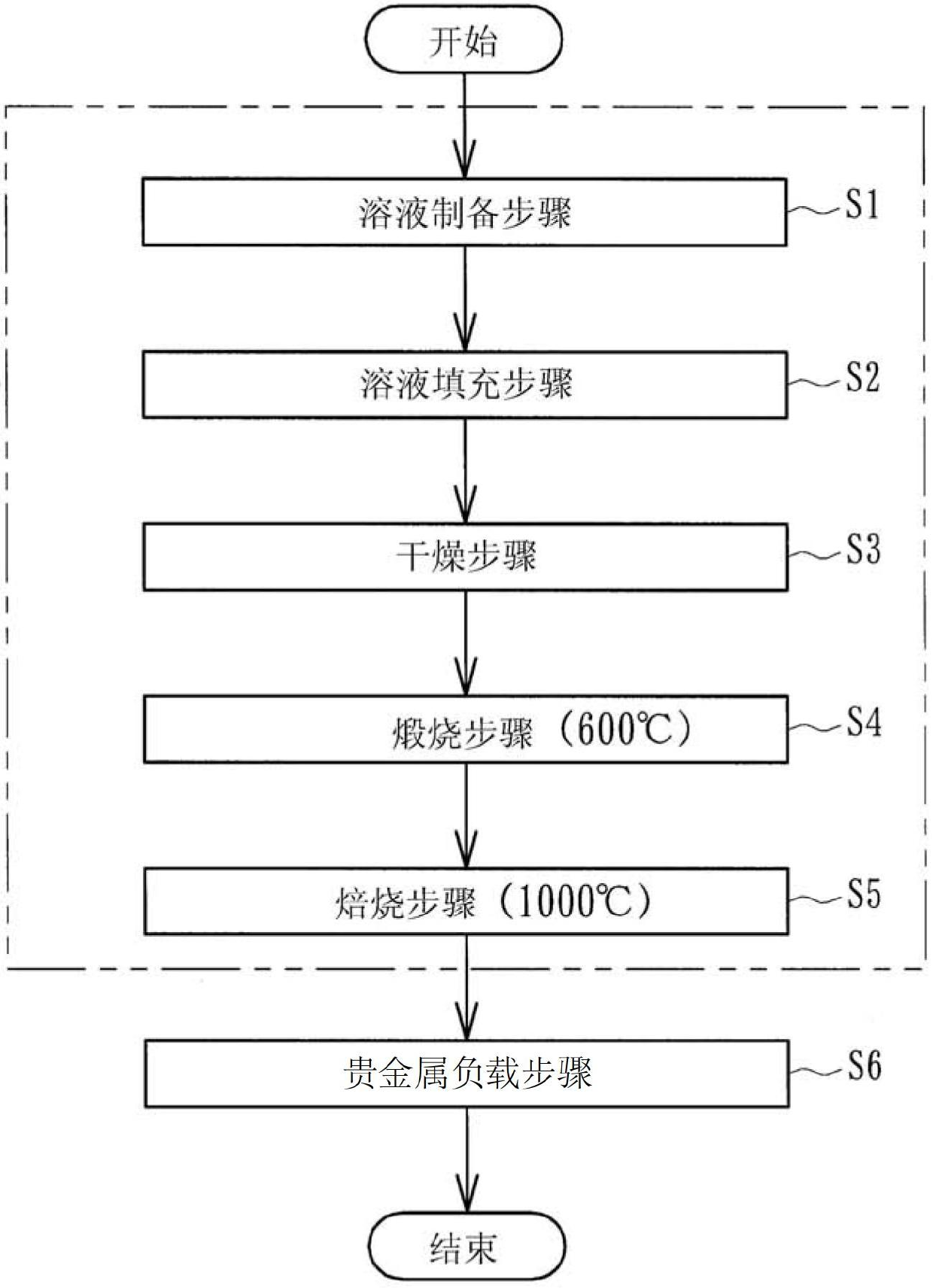

Method used

Image

Examples

Embodiment 3

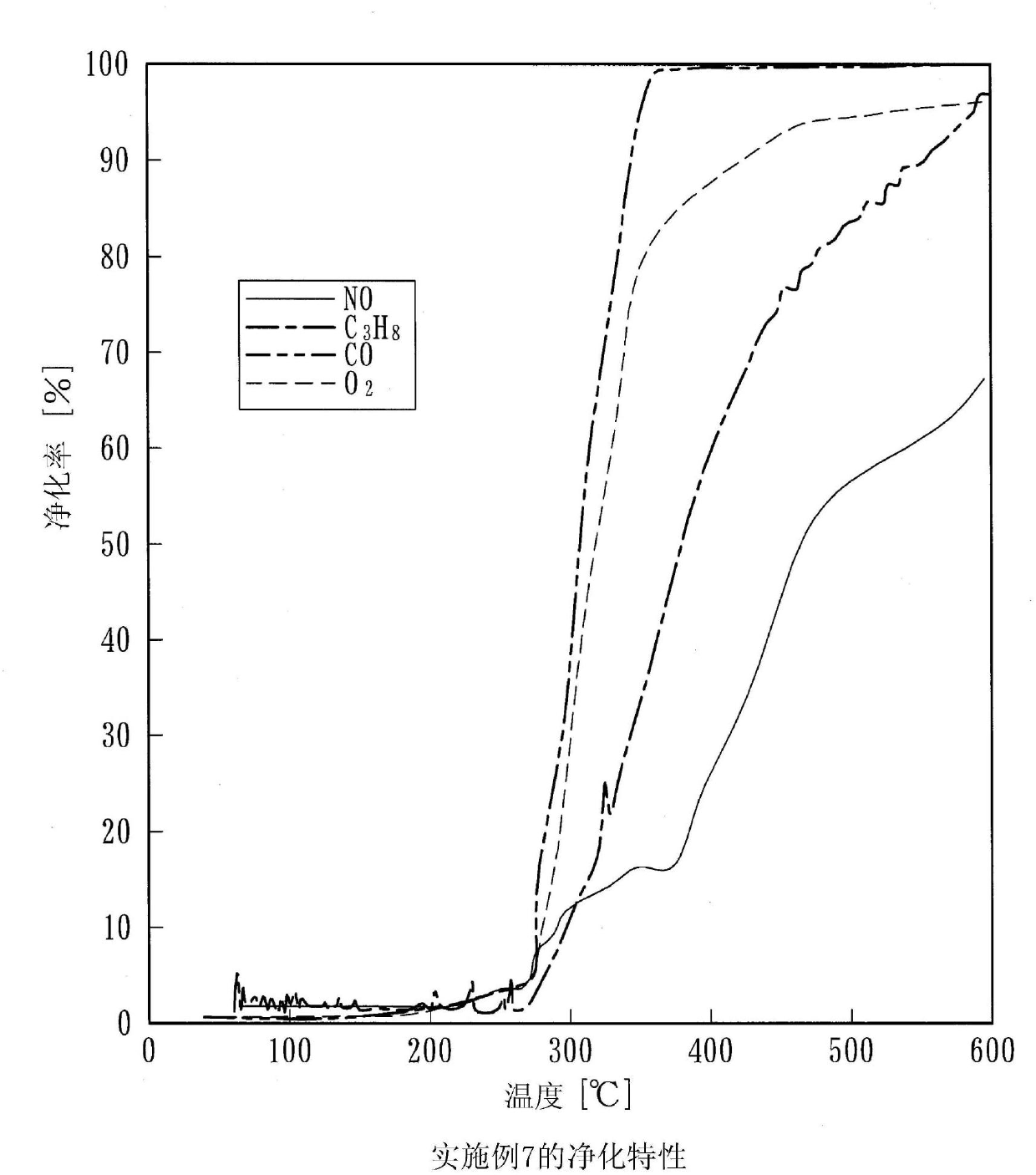

[0076] Then, the temperature of the catalyst layer was raised from room temperature to 600°C at a rate of 45°C / min. At each temperature during the heating process, the gas composition at the inlet and outlet of the catalyst layer was determined using infrared spectroscopy and magnetic oxygen analysis. Finally, the decontamination activity was evaluated. image 3 The evaluation results are shown. In addition, under similar conditions, the purification activity of the catalyst carrier of Example 3 was evaluated. Figure 4 The evaluation results are shown. In view of the above, even the catalyst support (Example 3) containing only 50 mol% spinel can achieve the oxidation activity of HC and CO and the reduction activity of NO. However, the degree of activity was found to be significantly lower compared with the catalyst on which Pd was supported, whereby the effect of Pd supported thereon could be confirmed.

[0077] In addition, in order to examine the thermal durability of t...

Embodiment 7

[0079] Durability at 900°C of Example 7

[0080]

[0081] (Experiment 4): Purification activity and thermal durability of the catalysts of Examples 8 to 10 and Comparative Example at 900°C

Embodiment 8

[0084] Durability at 900°C of Example 8

[0085]

[0086] Table 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com