Marine polyester fiber, and preparation method thereof

A yarn and polyester technology, applied in the direction of single-component polyester rayon, melt spinning, stretch spinning, etc., can solve the problems of reducing mechanical strength, fiber deformation, high risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The emulsifier can be selected in consideration of the process and equipment used for the preparation of polyester fibers, the type of polysiloxane compound, and the solvent, and is preferably a nonionic surfactant and the like.

[0069] In a preferred embodiment of the present invention, the emulsifier can be selected from nonionic surfactants of fatty acid monoglycerides, nonionic surfactants of fatty acid polyethylene glycol esters, nonionic surfactants of fatty acid sorbitan esters. One or more of ionic surfactants, fatty acid sucrose ester nonionic surfactants, fatty acid alkanolamide nonionic surfactants and polyethylene glycol condensed nonionic surfactants. Here, the fatty acid may have 8 to 22 carbon atoms.

[0070] More specifically, the nonionic surfactant may be selected from alkyl polyalkylene glycols, alkylaryl polyalkylene glycols, alkyl dimethylamine oxides, dialkylmethylamine oxides, alkylamidopropylamine oxides, alkyl glucamides, alkylpolyglycosides, ...

Embodiment 1

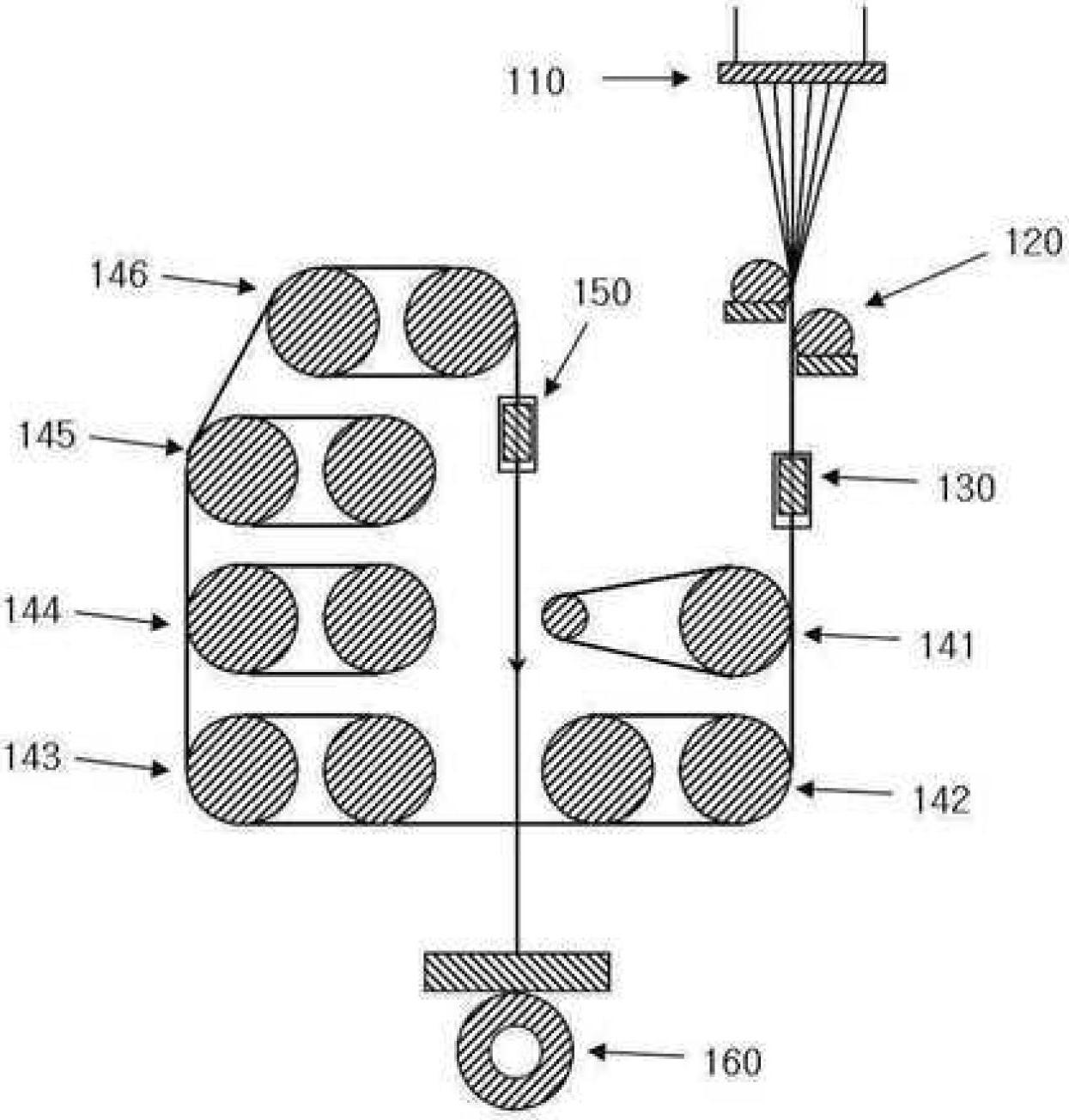

[0098]Melting solid-phase polymerized polyester chips having an intrinsic viscosity of 1.05 g / dL and 90% by weight or more of polyethylene terephthalate at 280°C or more, and The molten polyester is extruded through a spinneret. The extruded molten polyester was subjected to delayed quenching at a hood-heater temperature of 300°C, and was coated with polydimethylsiloxane (number average molecular weight 100,000 , the viscosity is 350cst) spinning oil component carries out surface treatment to the polyester fiber after quenching. At this time, 50% by weight of polydimethylsiloxane and 50% by weight of a conventional spinning solvent (n-paraffin) as a solvent were contained in the spinning oil.

[0099] The surface-treated polyester fibers passed through a pre-interlacer and were drawn through godet rolls at a winding speed of 3,000 m / min. At this time, the solvent is dried and removed in the stretching process.

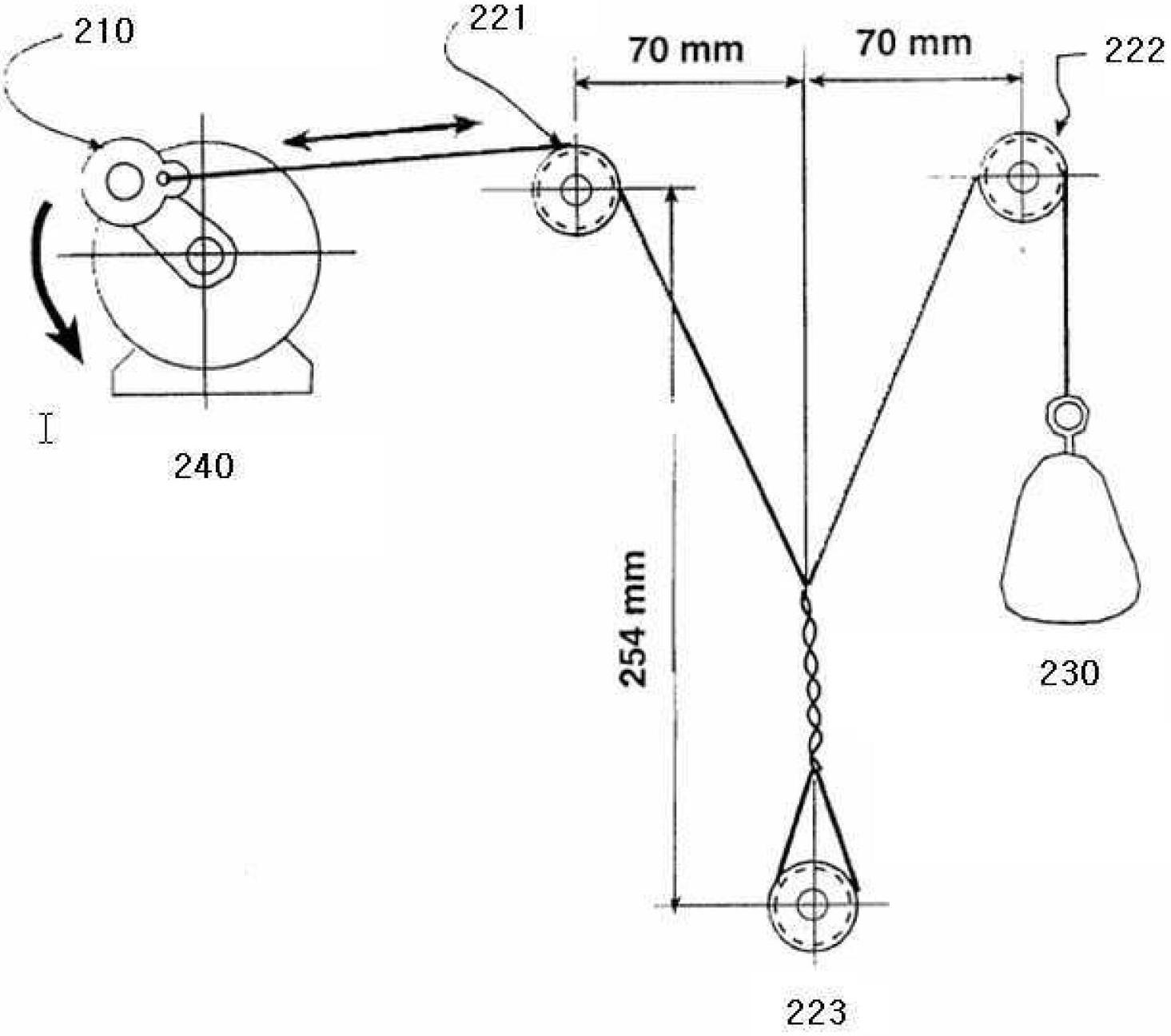

[0100] After the stretching process, at 3.0kg / cm 2 The stretc...

Embodiment 2

[0103] In addition to surface-treating polyester fibers with a spinning oil component containing 20% by weight of polydimethylsiloxane (number-average molecular weight: 100,000, viscosity: 350cst) and 80% by weight of water as a solvent, with The marine polyester yarn was prepared in the same manner as in Example 1.

[0104] The oil component was extracted from the prepared polyester yarn using carbon tetrachloride according to the extraction method, and the composition was analyzed by chromatography. As a result, 95% by weight of polydimethylsiloxane was found to be contained based on the total weight of the oil component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com