Phycocyanin microcapsule and preparation method of phycocyanin microcapsule

A phycocyanin and microcapsule technology, applied in the field of food biology, can solve the problems of light, heat and acid-base sensitivity, limited development and application, poor stability, etc., and achieves the effect of simple method, low professional quality requirements, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

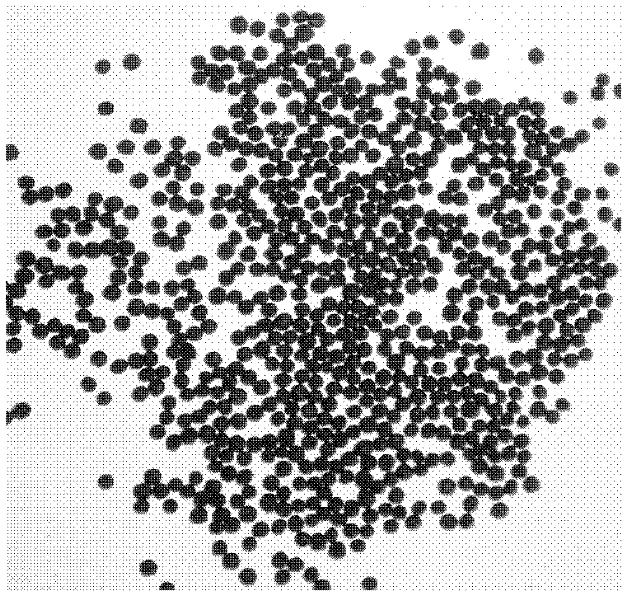

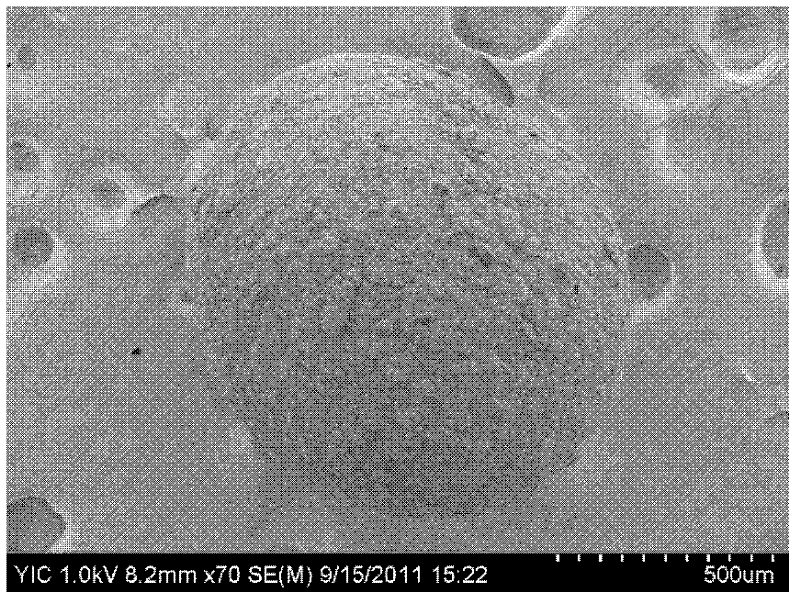

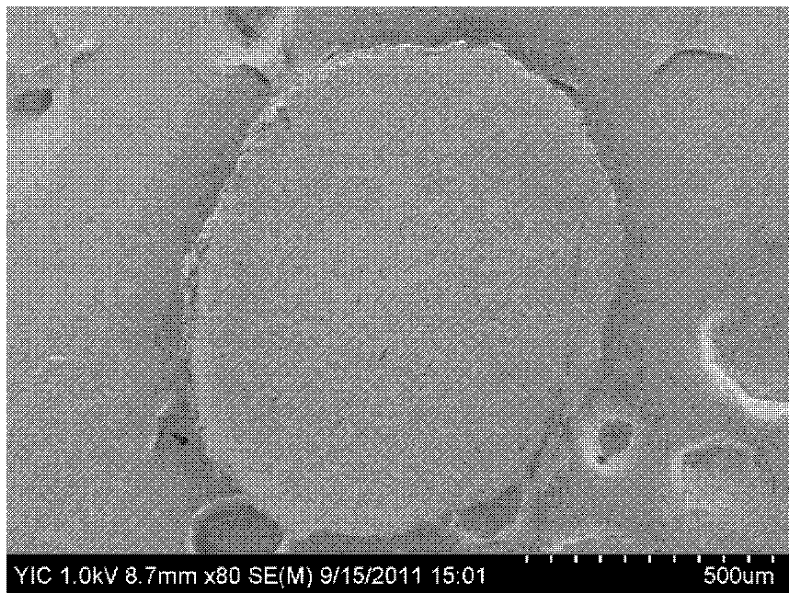

Image

Examples

Embodiment 1

[0026] Preparation of phycocyanin microcapsules:

[0027] Dissolving sodium alginate in water to prepare a sodium alginate solution, making the final concentration 4-6%; dissolving phycocyanin in water to prepare a phycocyanin solution, making the final concentration 5-9%;

[0028] Mix and homogenize the above sodium alginate solution and phycocyanin solution in equal volumes, set aside;

[0029] Then adopt extrusion equipment to extrude the above-mentioned homogeneous solution to the CaCl of 2-3% (mass percentage) by extrusion method 2 In the solution, stand and solidify for 30-60min;

[0030] After the above-mentioned solidification is washed with water, it is transferred to a chitosan solution with a concentration of 1.5-2.5% prepared with 1% acetic acid solution, and the coating is shaken for 60-120 minutes; then washed with water, filtered, and freeze-dried to obtain microcapsules.

[0031] The drying process is as follows: put the microcapsules into a petri dish, freez...

Embodiment 2

[0033] Preparation of phycocyanin microcapsules:

[0034] Sodium alginate solution was prepared by dissolving sodium alginate in water so that its final concentration was 4%; phycocyanin was prepared by dissolving phycocyanin in water so that its final concentration was 5%;

[0035] Mix and homogenize the above sodium alginate solution and phycocyanin solution in equal volumes, set aside;

[0036] Then the above-mentioned homogeneous solution is extruded to 2% CaCl by extrusion using an extruder 2 In the solution, let stand to solidify for 30min;

[0037] After the above-mentioned solidification is washed with water, it is transferred to a chitosan solution prepared with a concentration of 2% and 1% acetic acid solution, and the film is shaken for 90 minutes; then washed with water, filtered, and freeze-dried to obtain microcapsules.

[0038] The drying process is as follows: put the microcapsules into a petri dish, freeze overnight in a refrigerator at -20°C, put them into ...

Embodiment 3

[0048] Preparation of phycocyanin microcapsules:

[0049] Sodium alginate solution was prepared by dissolving sodium alginate in water so that its final concentration was 5%; phycocyanin was prepared by dissolving phycocyanin in water so that its final concentration was 9%;

[0050] Mix and homogenize the above sodium alginate solution and phycocyanin solution in equal volumes, set aside;

[0051] Then the above-mentioned homogeneous solution is extruded to 3% CaCl by extrusion using an extruder 2 In the solution, stand and solidify for 60 minutes;

[0052]After the above-mentioned solidification is washed with water, it is transferred to a chitosan solution prepared with a concentration of 1.5% and 1% acetic acid solution, and the membrane is shaken for 60 minutes; then washed with water, filtered, and freeze-dried to obtain microcapsules.

[0053] The drying process is as follows: put the microcapsules into a petri dish, freeze overnight in a refrigerator at -20°C, put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com