Artificial bile duct bionic stent with double-layered compound structure and preparation method of artificial bile duct bionic stent

An artificial bile duct, double-layer composite technology, which is applied in the device of human tubular structure, medical science, prosthesis, etc., can solve the problems of bile leakage, cannot effectively support bile circulation, threaten the life of patients, etc., and prevent bile leakage. , Good clinical application prospects, the effect of avoiding secondary surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

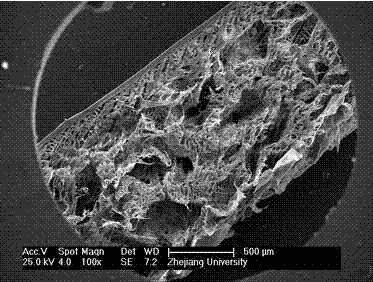

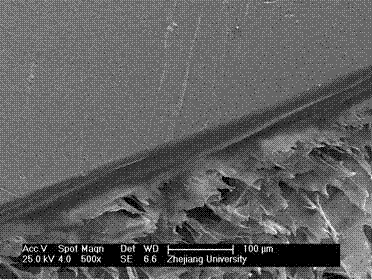

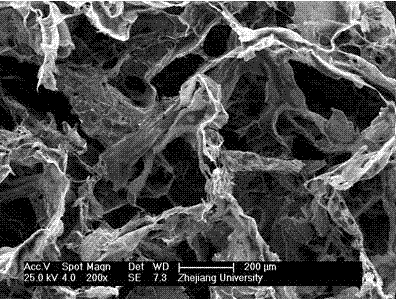

Image

Examples

example 1

[0026] 1) Coat a polycaprolactone solution with a mass concentration of 15% on a glass rod with a diameter of 5.5 mm, dry it, and remove it from the glass rod to obtain a dense film-like polycaprolactone tube.

[0027] 2) Use the dense film-like polycaprolactone tube prepared in step 1) as the inner tube, and place a glass tube with an outer diameter of 7.5 mm on the outer coaxial line, and fill the gap between the polycaprolactone tube and the glass tube Gelatin particles with a particle size of 280 μm are then injected with an ethanol solution with a volume concentration of 85% to infiltrate the gelatin particles and placed at a temperature of 70 o C oven, after the gelatin particles are bonded, take it out and store it at -25 o Freeze at a temperature of C, freeze-dry, and remove the glass outer tube to obtain a composite tube whose inner layer is a polycaprolactone tube and whose outer layer is a gelatin particle adhesive layer.

[0028] 3) Soak the composite tube in step...

example 2

[0032] 1) Coating a poly(lactic acid-glycolic acid) copolymer solution with a mass concentration of 15% on a glass rod with a diameter of 2 mm, drying it, and removing it from the glass rod to obtain a dense film-like poly(lactic acid-glycolic acid) glycolic acid) copolymer tubing.

[0033] 2) The dense film-like poly(lactic acid-glycolic acid) copolymer tube prepared in step 1) was used as the inner tube, and a glass tube with an outer diameter of 6 mm was sleeved on the outer coaxial line, and the poly(lactic acid-glycolic acid) ) between the copolymer tube and the glass tube is filled with gelatin particles with a particle size of 450 μm, and then injected with an ethanol solution with a volume concentration of 85% to infiltrate the gelatin particles, and placed in a temperature of 70 o C oven, after the gelatin particles are bonded, take it out and store it at -25 o Frozen at a temperature of C, freeze-dried, and removed the outer glass tube to obtain a composite tube wit...

example 3

[0036] 1) Coat a polycaprolactone solution with a mass concentration of 15% on a glass rod with a diameter of 1 mm, let it dry in the air, and remove it from the glass rod to obtain a dense film-like polycaprolactone tube.

[0037] 2) Take the dense film-like polycaprolactone tube prepared in step 1) as the inner tube, set a glass tube with an outer diameter of 3 mm on the outer coaxial line, and fill the gap between the polycaprolactone tube and the glass tube Gelatin particles with a particle size of 250 μm are then injected with an ethanol solution with a volume concentration of 85% to infiltrate the gelatin particles, and placed at a temperature of 70 o C oven, after the gelatin particles are bonded, take it out and store it at -25 oFreeze at a temperature of C, freeze-dry, and remove the glass outer tube to obtain a composite tube whose inner layer is a polycaprolactone tube and whose outer layer is a gelatin particle adhesive layer.

[0038] 3) Soak the composite tube i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com