Nano selenium micromolecular microbial polysaccharide as well as preparation method and application thereof

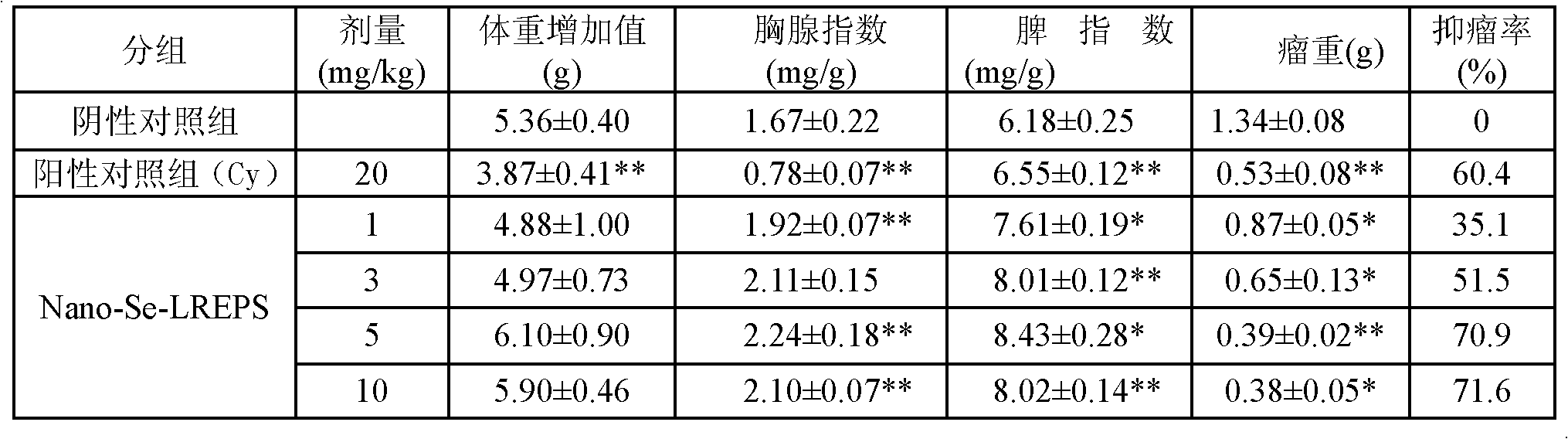

A microbial polysaccharide and small molecule technology, applied in application, food preparation, food science and other directions, can solve the problems of low polysaccharide yield and complex modification process, and achieve the effect of strong anti-tumor activity, strong competitive advantage and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take LREPS with a molecular weight of 11.4KD, and prepare a 6mg / mL LREPS solution with ultrapure water; at the same time, prepare a 60mg / mL Vc solution and a 60μg / mL SeO 2 the solution

[0031] (2) Mix 20mL of the above-mentioned LREPS solution and 2mL of the Vc solution, stir magnetically for 30min to fully mix into a homogeneous system.

[0032] (3) 48mL SeO 2 The solution was added dropwise into the above homogeneous system using a vacuum dropping funnel, stirred while dropping, and 50 mL of ultrapure water was added.

[0033] (4) The above system was reacted for 5 minutes under the ultrasonic state.

[0034] (5) The reaction system was dialyzed with ultrapure water for 30 hours, and it was detected that selenium was no longer precipitated in the dialyzed fluid.

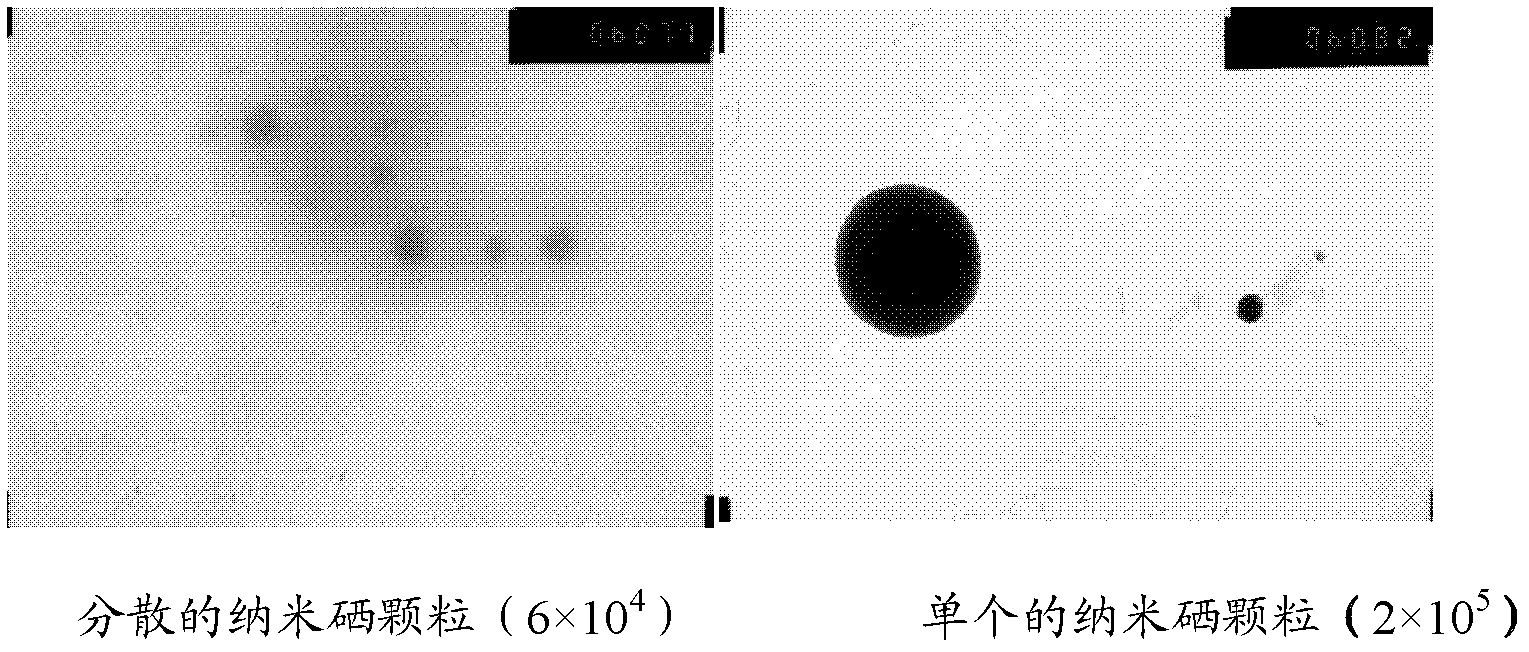

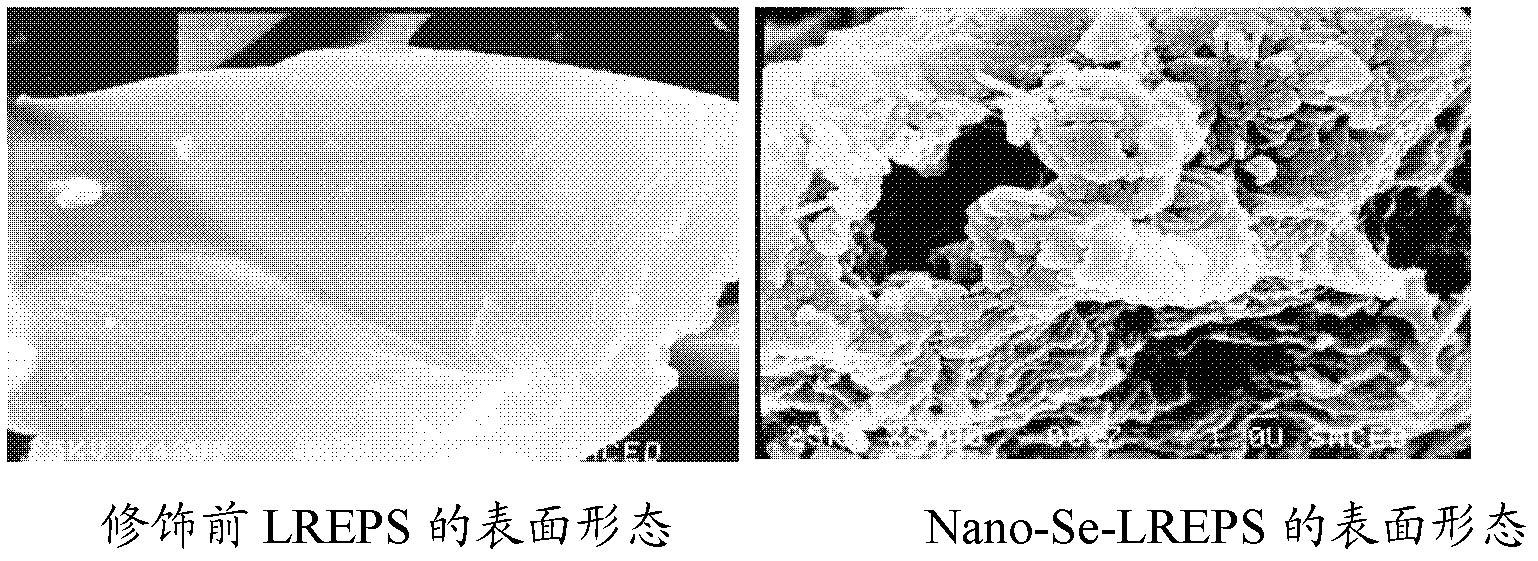

[0035] (6) Freeze drying to obtain Nano-Se-LREPS, the selenium content of which is 16.2 μg / mg, and the average particle diameter of selenium particles is 380 nm. Nano-selenium small-molecule microbi...

Embodiment 2

[0037] (1) Take LREPS with a molecular weight of about 11.0KD, and prepare a 6mg / mL LREPS solution with ultrapure water; at the same time, prepare a 60mg / mL Vc solution and a 60μg / mL SeO 2 the solution

[0038] (2) Mix 20mL of the above-mentioned LREPS solution and 1.6mL of Vc solution, and stir magnetically for 30min to fully mix into a homogeneous system.

[0039] (3) 32mL SeO 2 The solution was added dropwise into the above homogeneous system using a vacuum dropping funnel, stirred while dropping, and 50 mL of ultrapure water was added.

[0040] (4) The above system was reacted for 7 minutes in the ultrasonic state.

[0041] (5) Dialyze the reaction system with ultrapure water until it is detected that there is no selenium in the dialyzed fluid.

[0042] (6) Freeze drying to obtain Nano-Se-LREPS, the selenium content of which is 15.2 μg / mg, and the average particle diameter of selenium particles is 370 nm.

Embodiment 3

[0044] (1) Take LREPS with a molecular weight of about 10.2KD, and prepare a 6mg / mL LREPS solution with ultrapure water; at the same time, prepare a 60mg / mL Vc solution and a 60μg / mL SeO 2 solution.

[0045] (2) Mix 10 mL of the above-mentioned LREPS solution and 1.2 mL of Vc solution, and stir magnetically for 30 minutes to fully mix them into a homogeneous system.

[0046] (3) 20mL SeO 2 The solution was added dropwise to the above homogeneous system using a vacuum dropping funnel, stirred while dropping, and 25 mL of pure water was added.

[0047] (4) The above system was reacted for 10 minutes under ultrasonic state.

[0048] (5) Dialyze the reaction system with ultrapure water until the Vc detects that there is no selenium in the dialyzed fluid.

[0049] (6) Freeze drying to obtain Nano-Se-LREPS, the selenium content of which is 16.4 μg / mg, and the average particle diameter of selenium particles is 380 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com