A method for preparing ordered arrays of titania hierarchical nanotubes composed of anatase single crystal particles with controllable morphology

A technology of nanotube arrays and titanium dioxide, which is applied in the field of preparation of ordered arrays of titanium dioxide hierarchical nanotubes, can solve the problem that complex single crystal structures are difficult to synthesize, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

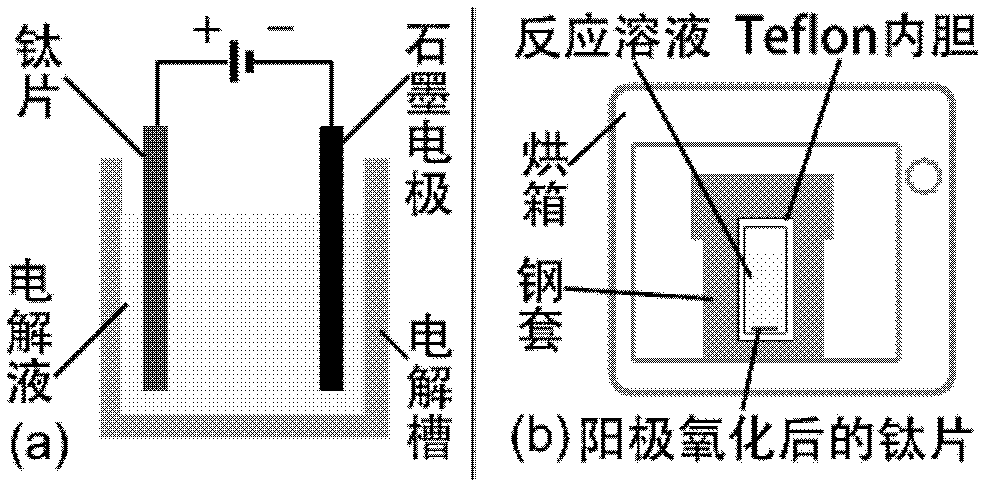

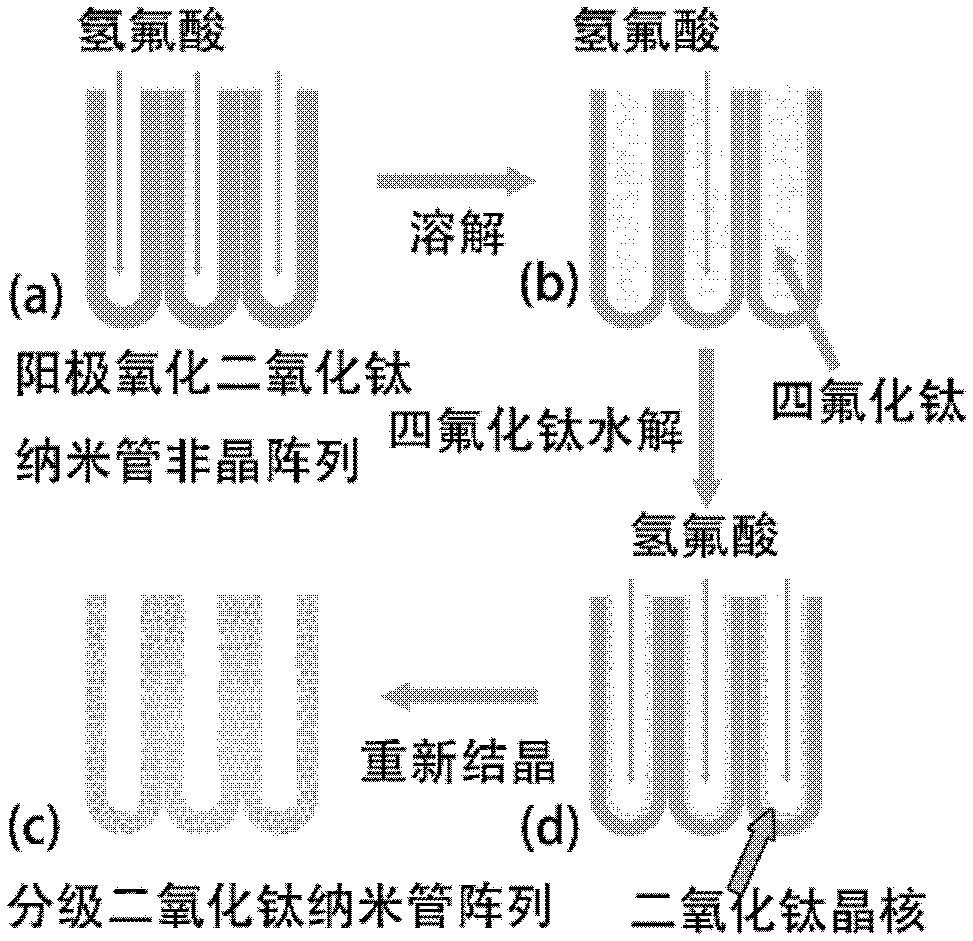

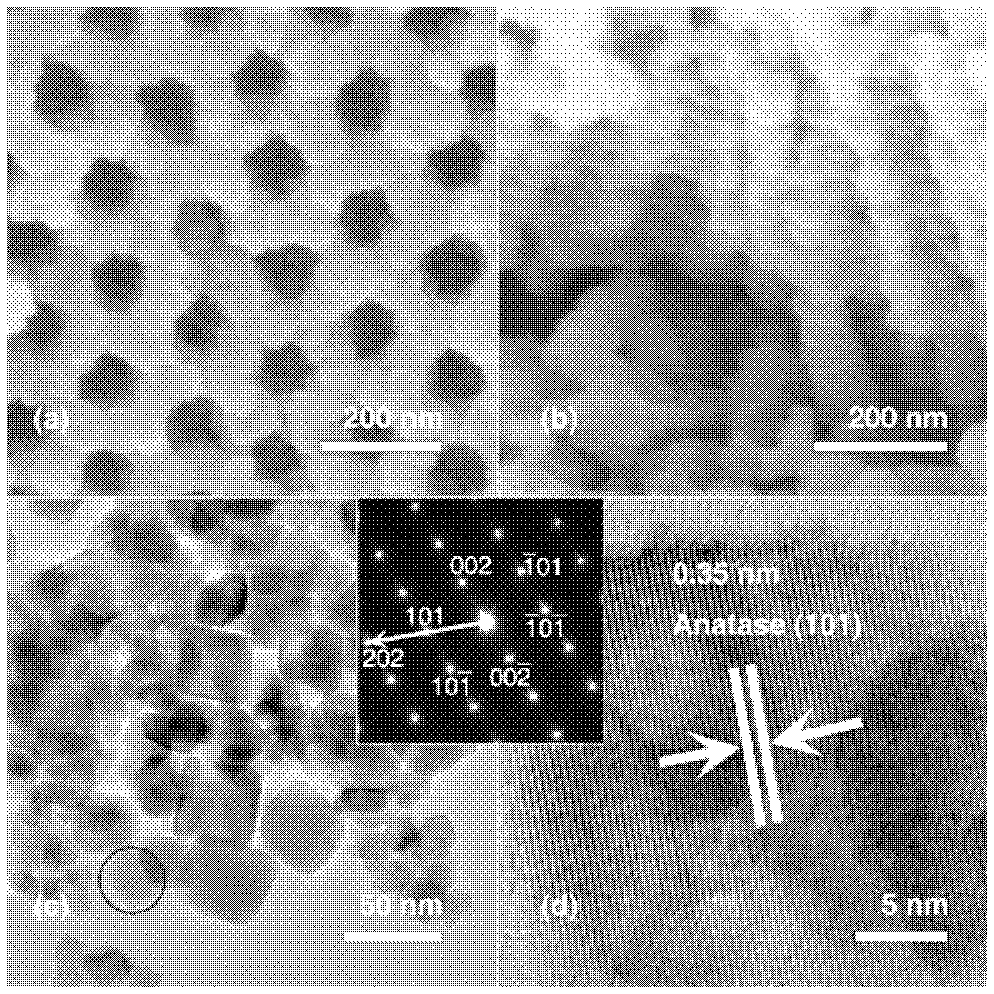

[0018] A method for preparing an ordered array of titanium dioxide hierarchical nanotubes composed of anatase single crystal particles with controllable morphology, comprising the following steps:

[0019] (1) Ultrasonic cleaning of 99.9% pure titanium sheets in a mixed solution of ethanol and acetone with a volume ratio of 1:1 for about 30 minutes to remove organic matter on the surface, and then repeated ultrasonic cleaning with deionized water, nitrogen flow at room temperature Blow dry, then put the cleaned and dried titanium sheet into an electrolytic cell containing 0.2M hydrofluoric acid ethylene glycol electrolyte solution, apply a constant voltage of 100V for anodic oxidation, and the oxidation time is about 1 hour, then put the anode The oxidized titanium sheet is taken out, placed in absolute ethanol for ultrasonic vibration, and the disordered anodized titanium dioxide nanotubes on the surface are removed, leaving an ordered array layer of anodized titanium dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com