Solid electrolyte interface modification film for lithium battery and preparation method thereof

A solid electrolyte and interface modification technology, applied in hybrid batteries, battery pack components, hybrid battery components, etc., can solve the problem of reducing the discharge current and discharge power of lithium-air batteries, large ion transmission impedance, and reducing battery discharge performance, etc. problems, to achieve the effects of easy large-area preparation, obvious performance improvement, and improved discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

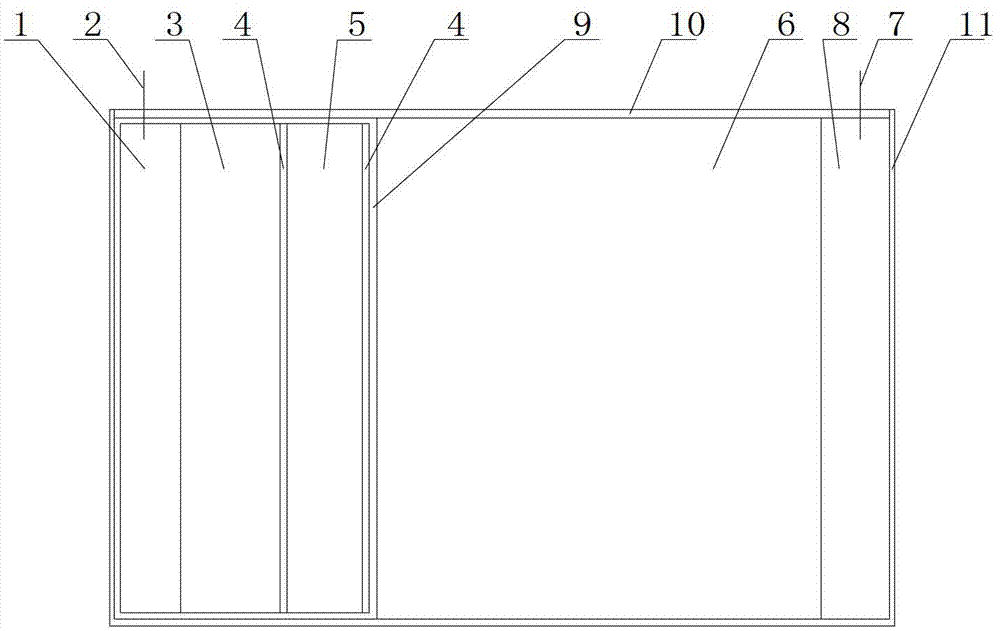

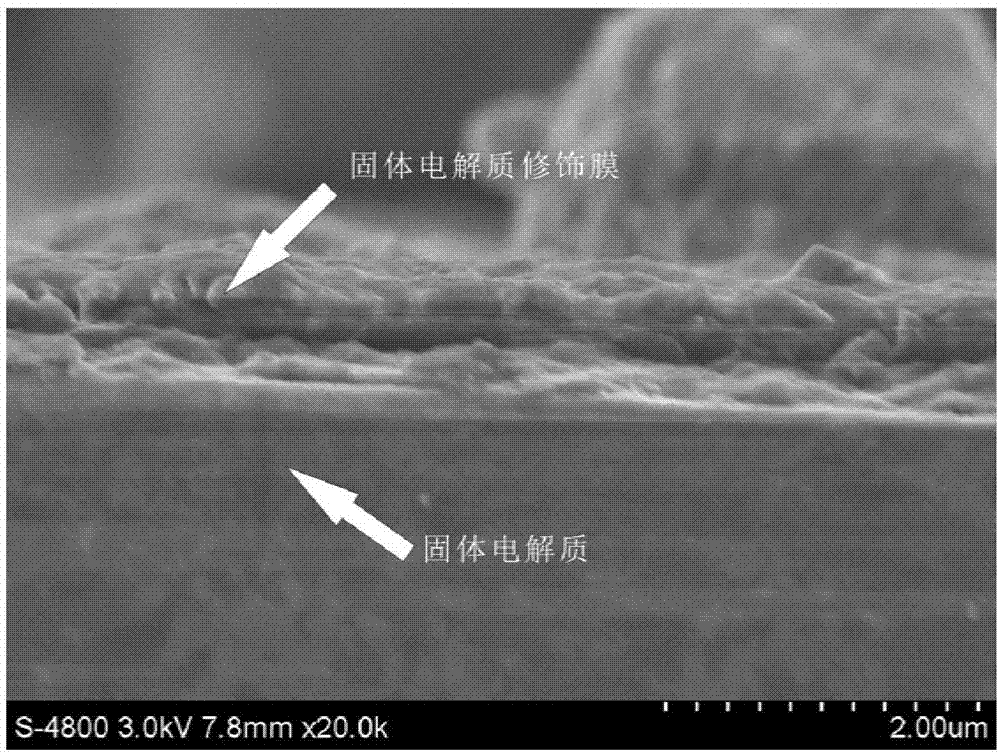

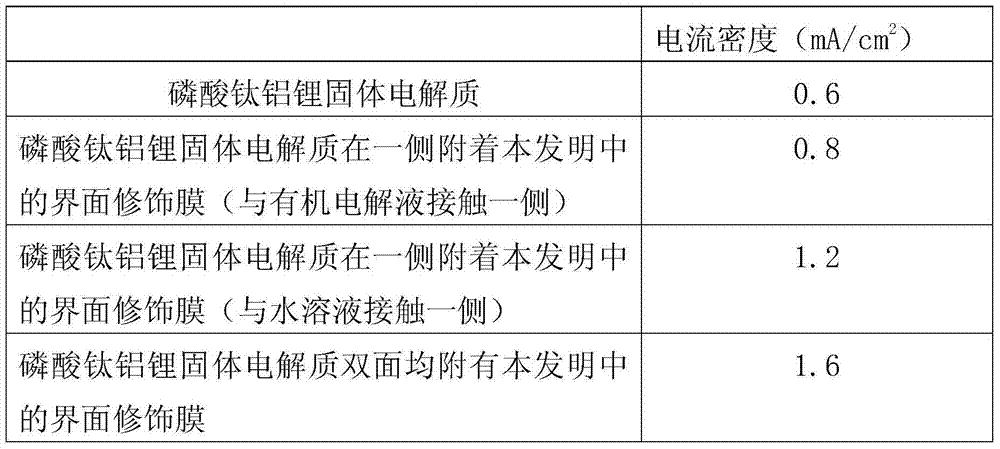

[0024] In this example, lithium titanium aluminum phosphate was selected as the solid electrolyte, and the interface modification film was prepared by magnetron sputtering.

[0025] The preparation steps of the solid electrolyte interface modification membrane:

[0026] (1) Lithium titanate with a mass ratio of 15:1 is selected as the lithium ion active material and mixed evenly with water;

[0027] (2) Put the lithium titanate mixed with water in step (1) into a steel mold and press it into a cylinder as a target material, place the target material in a sintering furnace, sinter at 800°C for 8 hours, and cool naturally with the furnace;

[0028] (3) Place the sintered and cooled target in step (2) in a magnetron sputtering apparatus, fill the magnetron sputtering apparatus with argon gas, and perform magnetron sputtering on one side of the solid electrolyte; modify the interface of the solid electrolyte according to the battery model According to the needs of film thickness,...

Embodiment 2

[0030] In this example, lithium silicon phosphorus sulfur was selected as the solid electrolyte, and the interface modification film was prepared by laser evaporation.

[0031] The preparation steps of the solid electrolyte interface modification membrane:

[0032] (1) and (2) are identical with step (1) and (2) among the embodiment 1;

[0033] (3) To place the sintered and cooled target in step (2) in a laser evaporator, and fill the laser evaporator with an argon-oxygen mixed gas with a volume ratio of oxygen content of 10%, and perform laser evaporation on one side of the solid electrolyte; according to the battery model To meet the needs of solid electrolyte interface modification film thickness, adjust the power, temperature and laser evaporation time of the target at any time. The adjustment range is: power 200-500W, radiation temperature 10-200℃, laser evaporation time 2-10 hours, solid A layer of lithium ion active material with a thickness of 0.01-10 μm will be attac...

Embodiment 3

[0035] In this example, lithium phosphorus oxynitride was selected as the solid electrolyte, and the interface modification film was prepared by laser evaporation.

[0036] The preparation steps of the solid electrolyte interface modification membrane:

[0037] (1) and (2) are identical with step (1) and (2) among the embodiment 1;

[0038](3) Place the sintered and cooled target in step (2) in an electron beam evaporator, fill the electron beam evaporator with an argon-oxygen mixed gas with an oxygen content of 10% by volume, and perform electron beam evaporation on one side of the solid electrolyte; According to the needs of the battery model for the thickness of the solid electrolyte interface modification film, the power, temperature and electron beam evaporation time of the target can be adjusted at any time. The adjustment range is: power 200-400W, radiation temperature 10-100°C, electron beam evaporation time 2 -10 hours, a layer of lithium ion active material with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com