Method for preparing antioxidant peptide through ultrasonic-microwave synergetic enzymatic hydrolysis

An antioxidant peptide and ultrasonic technology, applied in the field of bioengineering, to achieve high economic and social benefits, shorten the time of enzymatic hydrolysis, and reduce the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

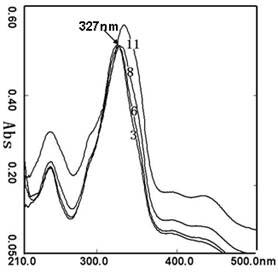

[0037] Example 1 Optimization of ultrasonic-microwave synergistic enzymatic hydrolysis to prepare antioxidant peptides by response surface methodology

[0038] 1. Materials and Equipment

[0039] 1.1 Raw materials and reagents

[0040] Salmon collagen (SC) was purchased from Wuhan Tiantianhao Biological Products Co., Ltd.; Tris-HCl salt was purchased from Sigma; alkaline protease was purchased from Pangbo Biotechnology Co., Ltd.; other chemical reagents were of domestic analytical grade.

[0041] It should be noted that the alkaline protease used in the present invention is a kind of proteolytic enzyme formed by submerged fermentation, extraction and refining of Bacillus licheniformis 2709 bred by bacterial protoplast mutagenesis, and its main enzyme component is lichen Bacillus protease. The range of enzyme activity is 200,000 u / g, purchased from Pangbo Biotechnology Co., Ltd.

[0042] 1.2 Experimental equipment

[0043] UV-Vis Spectrophotometer, UV-2450; Precision pH M...

Embodiment 2

[0087] Example 2 The method of the present invention for preparing antioxidant peptides by ultrasonic-microwave synergistic enzymatic hydrolysis

[0088] 1) Preparation of enzymatic hydrolysis substrate: Prepare 50 mL of salmon protein solution with a concentration of 5 mg / mL in deionized water as the enzymatic hydrolysis substrate.

[0089] 2) Ultrasonic-microwave-assisted enzymatic hydrolysis: adjust the pH value of the enzymatic hydrolysis substrate to 8.2, then add 0.002 g of alkaline protease, and put it in a water bath at 41°C for 5 minutes.

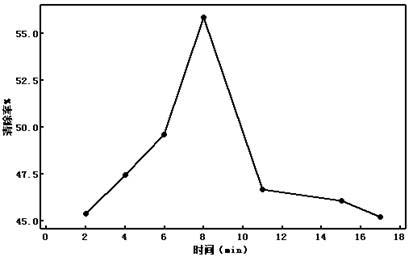

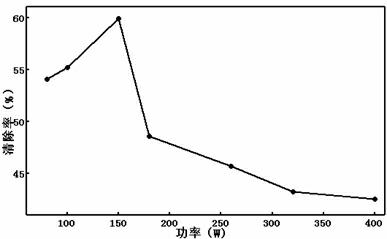

[0090] 3) Turn on the computer microwave-ultrasonic combined catalytic synthesizer to perform ultrasonic-microwave assisted enzymolysis on the enzymatic hydrolyzate, in which the insertion depth of the ultrasonic probe is fixed. The microwave power was 500W, the ultrasonic power was 100W, and the ultrasonic-microwave treatment temperature was 41°C. After treatment for 9.7 minutes, the enzymatic hydrolysis was continued, and the e...

Embodiment 3

[0093] Example 3 The effect of using different methods to assist enzymatic hydrolysis to prepare antioxidant peptides

[0094] (1) Prepare 50 mL of salmon protein solution with a concentration of 5 mg / mL in deionized water as the substrate for enzymatic hydrolysis.

[0095] (2) Prepare 4 copies of the enzymatic hydrolysis substrates in (1), record them as No. 1-4, adjust to the optimum pH value of the enzyme at 8.2, then add 0.002g of alkaline protease respectively, put them in a water bath at 41°C Enzyme hydrolysis for 5min.

[0096] No. 1: 100W, ultrasonic treatment at 41°C for 10 minutes, continue enzymatic hydrolysis and place it in a water bath at 41°C, inactivate the enzyme at 100°C when the total enzymatic hydrolysis reaction time reaches 2 hours, after cooling, centrifuge to take the supernatant, and detect its superoxide anion radical scavenging rate.

[0097] No. 2: 500W, microwave treatment at 41°C for 10 minutes, continue enzymatic hydrolysis and place it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com