Plasma arc melting enrichment method and plasma arc melting enrichment device for recycling metal elements of platinum group

A technology of metal elements and plasma, applied in the direction of improving process efficiency, can solve problems such as production difficulties, waste of energy consumption, and unsatisfactory problems, and achieve the effects of fast smelting reduction, convenient pouring, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

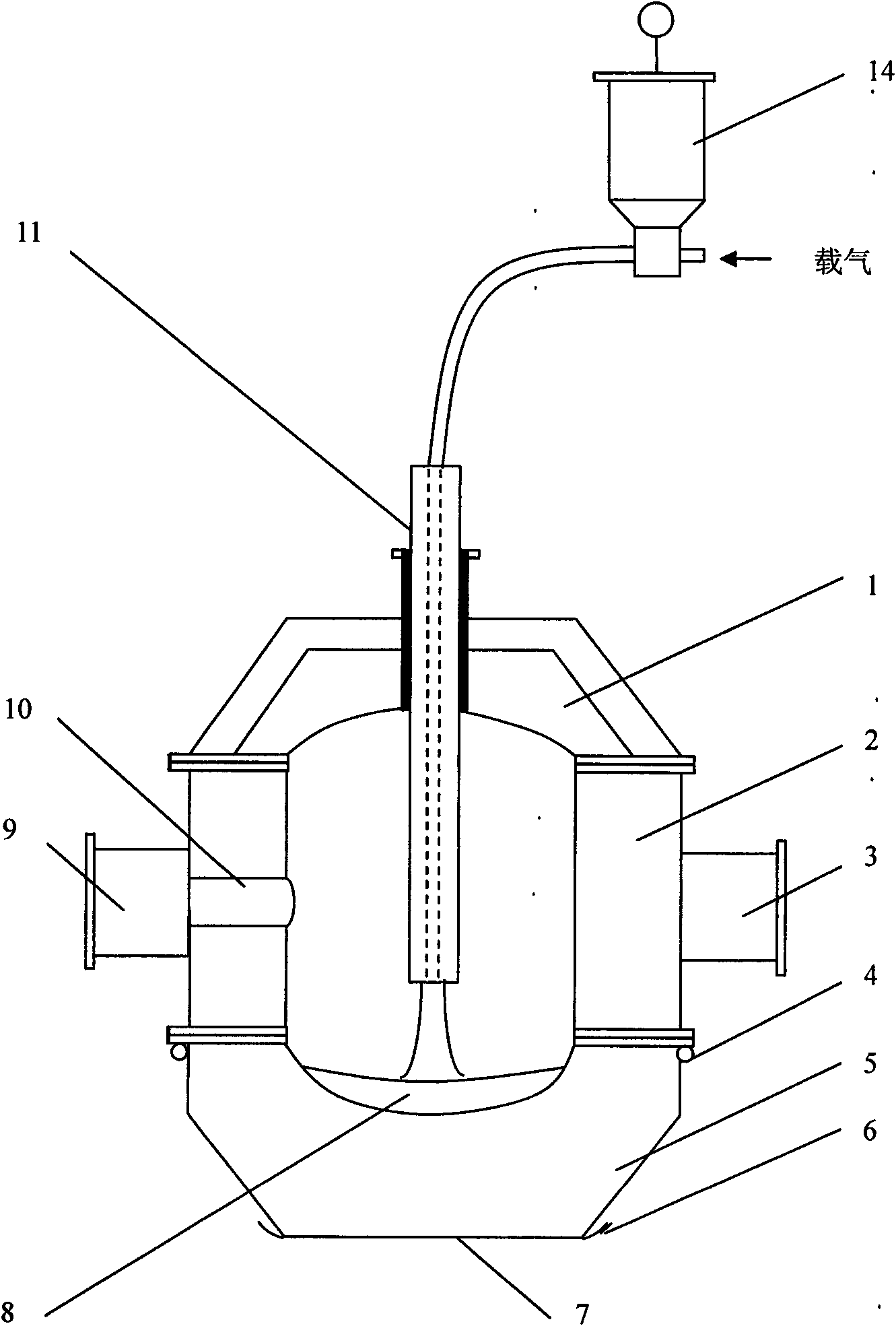

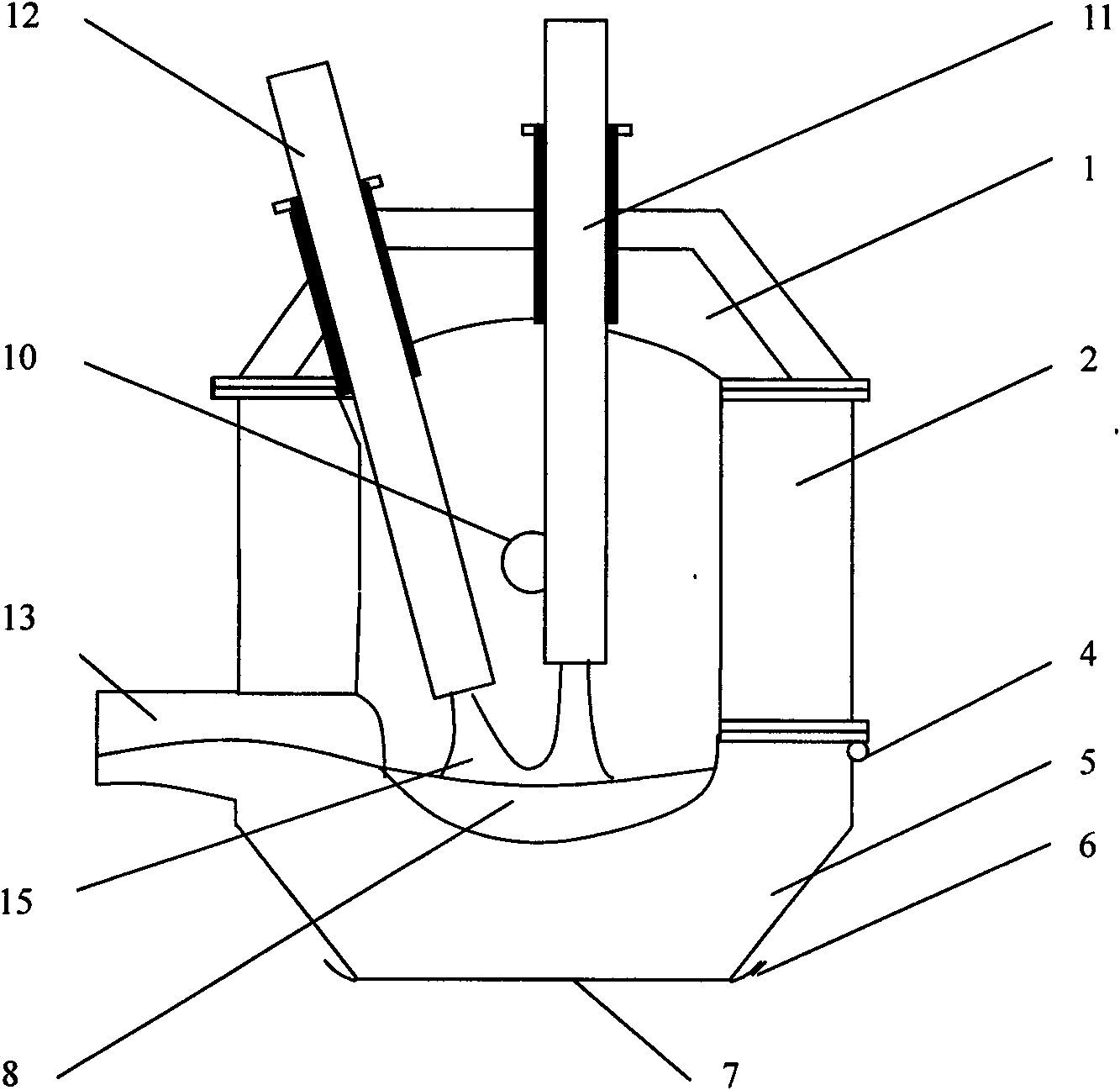

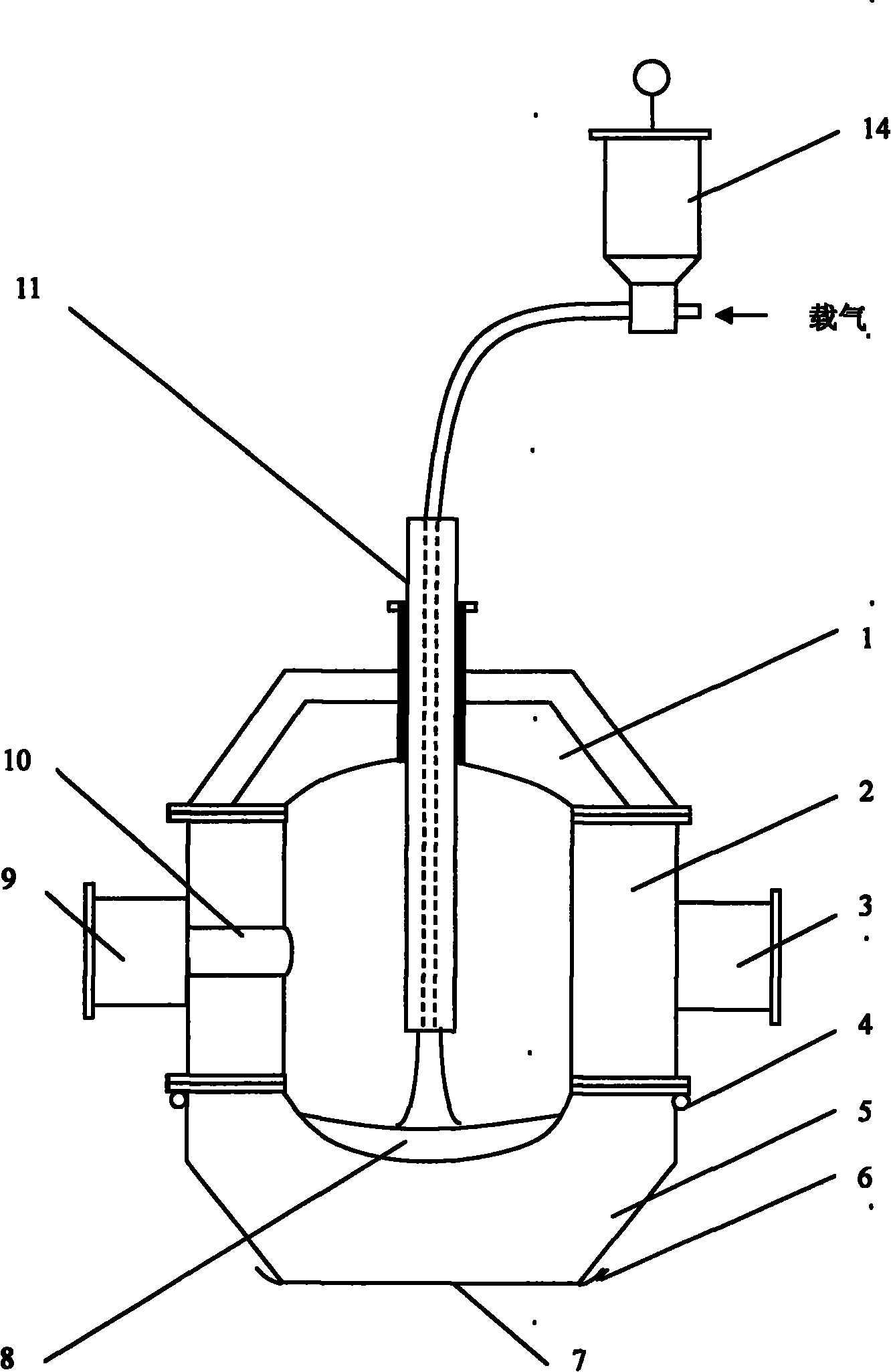

[0016] As shown in the figure: a plasma arc melting enrichment method for recovering platinum group metal elements, the method includes mixing and grinding the pretreated platinum group metal element-containing material, iron oxide, solid carbon reducing agent and flux Finally, put it into the powder spray tank, use the carrier gas inert gas or reducing gas to suspend and transport, pass through the axial center hole of the graphite electrode in the closed plasma arc melting furnace, and directly send it into the plasma arc, reduce and melt into the melting furnace. Pool, the platinum group metal elements are collected and carried by the reduced nascent collector iron, pass through the molten slag layer, and enter the noble iron melt layer. The temperature of the molten pool is 1200-1550 ° C. After standing for 5-30 minutes, it is discharged from the furnace body.

[0017] A plasma arc melting device for recovering platinum group metal elements, the melting device includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com