Optical fiber and manufacturing method thereof

A technology of optical fiber preform and optical fiber, which is applied in the direction of cladding optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve the problems affecting the reduction of optical fiber transmission loss, the difficulty of realizing low-attenuation optical fiber, affecting the strength and service life of optical fiber, etc., to achieve Effect of Transmission Loss Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

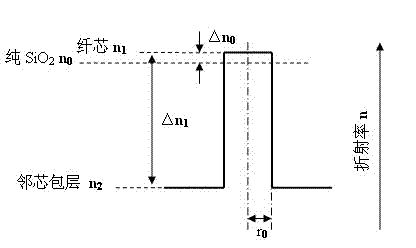

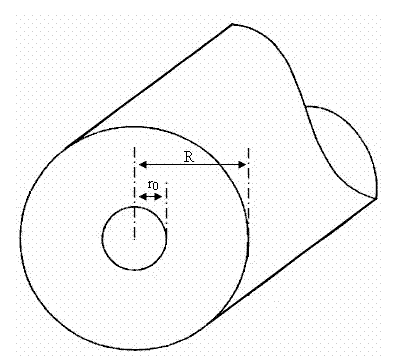

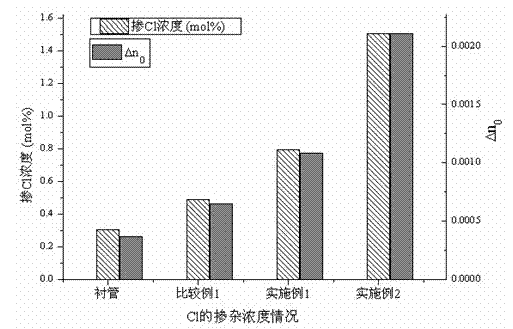

[0033] Example 1 , the optical fiber material is prepared by the in-tube method, the concentration difference △[F] between the cladding and core materials is 1.9 mol%, and the difference △[OH] between the core and cladding materials is 1×10 -6 mol%, the concentration difference △[Cl] between the fiber core and the cladding material is 1.52 mol%, and the fiber core material is not doped with alkali metal. image 3 It is the change of the refractive index caused by the doping of different concentrations of Cl, and the different doping concentrations of Cl are adjusted by changing the proportion of the reaction gas and the moving speed of the reaction zone. Figure 4 is the Cl concentration (mol%) contained in the single-mode optical fiber in the comparative example.

Embodiment 2

[0034] Example 2 , the optical fiber material is prepared by the in-tube method. The concentration difference △[F] between the cladding and core materials is 2.33 mol%, the difference △[OH] between the core and cladding materials is 0.01 ppm_mol. The concentration difference △[Cl] of the cladding material doped with chlorine is 1.53 mol%, and the fiber core material is not doped with alkali metal.

Embodiment 3

[0035] Example 3 , the optical fiber material is prepared by the in-tube method, the concentration difference △[F] between the cladding and core materials is 3.5 mol%, the difference △[OH] of the hydroxyl concentration between the core and cladding materials is 0.01 ppm_mol, and the core and cladding materials are 0.01 ppm_mol. The concentration difference △[Cl] of the cladding material doped with chlorine is 2.84 mol%, and the fiber core material is not doped with alkali metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scattering coefficient | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com