Polyurethane/polyurea composite protective layer and preparation method thereof, and application of polyurethane/polyurea composite protective layer in concrete shielding

A technology of polyurethane and protective layer, which is applied in the field of preparation and its application in concrete surface protection, and can solve the problems of high price, easy peeling, and easy falling off of the whole layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

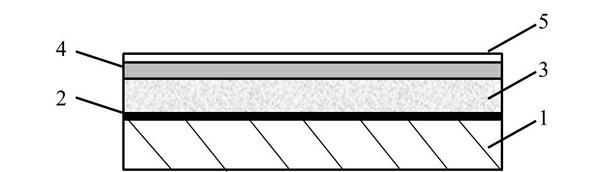

[0034] Embodiment 1, a kind of high-performance waterproof, anticorrosion, the preparation method of protective polyurethane / polyurea composite protective layer

[0035] Use a low-pressure water gun to treat the surface of the concrete base 1. After drying, apply 0.3mm of two-component polyurethane material. After the surface is dry, apply the second layer of 1mm. After the surface is dry, continue to apply the third layer of 0.7mm to obtain a thickness of 2mm. Polyurethane elastic layer 3; after the third layer of polyurethane coating is dry (about 3 hours at room temperature), spray polyurea layer 4 with a thickness of 1 mm in time, and cure for 2 days to obtain a composite protective layer that is waterproof, anti-corrosion, and protective.

[0036] The composite protective layer obtained in the present embodiment has a tensile strength of 12.0MPa, a tear strength of 45N / mm, and a Shore A hardness of 83. The elongation at break of the polyurethane / polyurea composite protecti...

Embodiment 2

[0037] Example 2. Preparation of a high-performance waterproof, anti-corrosion and protective composite protective layer (using topcoat)

[0038] Other steps are with embodiment 1, after spraying polyurea, brush anti-ultraviolet, wear-resisting topcoat, form topcoat layer 5, topcoat consumption is by 0.15Kg / m 2 use.

Embodiment 3

[0039] Example 3. Preparation of a high-performance waterproof, anti-corrosion, and protective composite protective layer (using a base surface treatment agent)

[0040] The surface of the concrete base 1 is treated by sandblasting, and the amount of base surface treatment agent is 0.2Kg / m 2 After spraying the base surface treatment agent to dry to form the base surface treatment layer 2, apply 0.2mm of two-component polyurethane material, and apply the second layer of 0.5mm after the surface of the polyurethane coating is dry, and apply the third layer of 0.5mm in the same way. mm, the fourth layer is 0.5mm, and a 1.7mm thick polyurethane elastic layer 3 is obtained; after the surface of the fourth layer of polyurethane coating is dry, spray a polyurea layer 4 with a thickness of 2mm in time, and cure for 3 days to obtain waterproof, anti-corrosion and protection With an integral composite protective layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com