Water-phase synthesis method of sodium azide

A technology of sodium azide and hydrazine hydrate, applied in the direction of azide acid/azide/halide azide, chemical recovery, etc., can solve the problems of low utilization rate of raw nitrite, long reaction period and high production cost , to achieve the effect of good product purity, low cost and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix 66.0g (0.66 moles) of 98% concentrated sulfuric acid and pure water to form a 50% sulfuric acid solution, and drop the obtained sulfuric acid solution into a mixed system consisting of 90.6g (1.3 moles) of sodium nitrite and 64.4g (1.33 moles) of ethanol while stirring During the process, control the reaction temperature at 25-40°C, start to condense and collect liquid ethyl nitrite, and drop sulfuric acid in about 2 hours. After adding the acid, keep the reaction at 30-40°C for 0.5h until liquid ethyl nitrite is no longer received, and a total of 90.6g of ethyl nitrite is obtained.

[0020] Mix 62.5g (1.0 mole) of hydrazine hydrate with 137.5g (1.1 mole) of 32% liquid caustic soda and cool down to 10-15°C, add 1.5g of 1wt% tetrabutylammonium bromide solution, and dissolve the liquid ethyl nitrite obtained above Add all to the system, seal the reaction, keep the reaction temperature at 15-20°C, react for 10 hours, and finally the system pressure reaches 0.32MPa. Op...

Embodiment 2

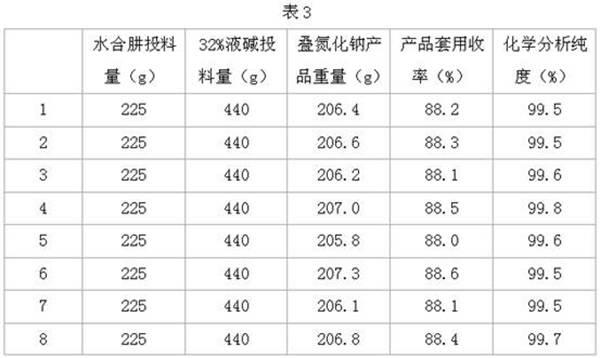

[0022] Other conditions are constant, only change the mol ratio of hydrazine hydrate, sodium hydroxide and ethyl nitrite, react according to the step of embodiment 1, reaction result is shown in Table 1:

[0023]

[0024] From the experimental results, the yield is better when the molar ratio of hydrazine hydrate: sodium hydroxide: liquid ethyl nitrite is 1:1.1-1.2: 1.2-1.3.

Embodiment 3

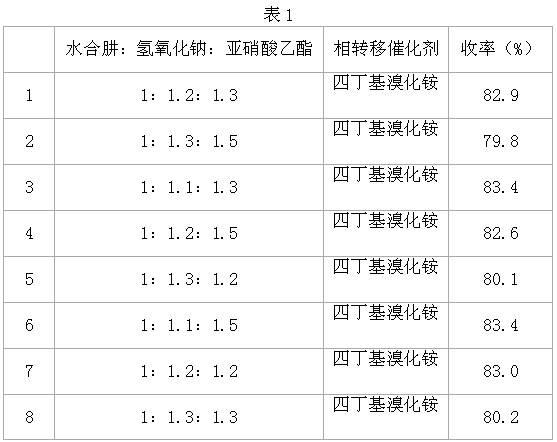

[0026] Other conditions are unchanged, only the type of phase transfer catalyst, the catalyst is all configured as a 1wt% solution, the addition is 1.5g, and the reaction is carried out according to the steps of Example 1. The reaction results are shown in Table 2:

[0027]

[0028] From the experimental results, the catalytic effects of several catalysts are not much different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com