Photo/electricity Fenton device for treating refractory organic wastewater

An organic waste water, refractory technology, applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high energy consumption, unsatisfactory treatment effect, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

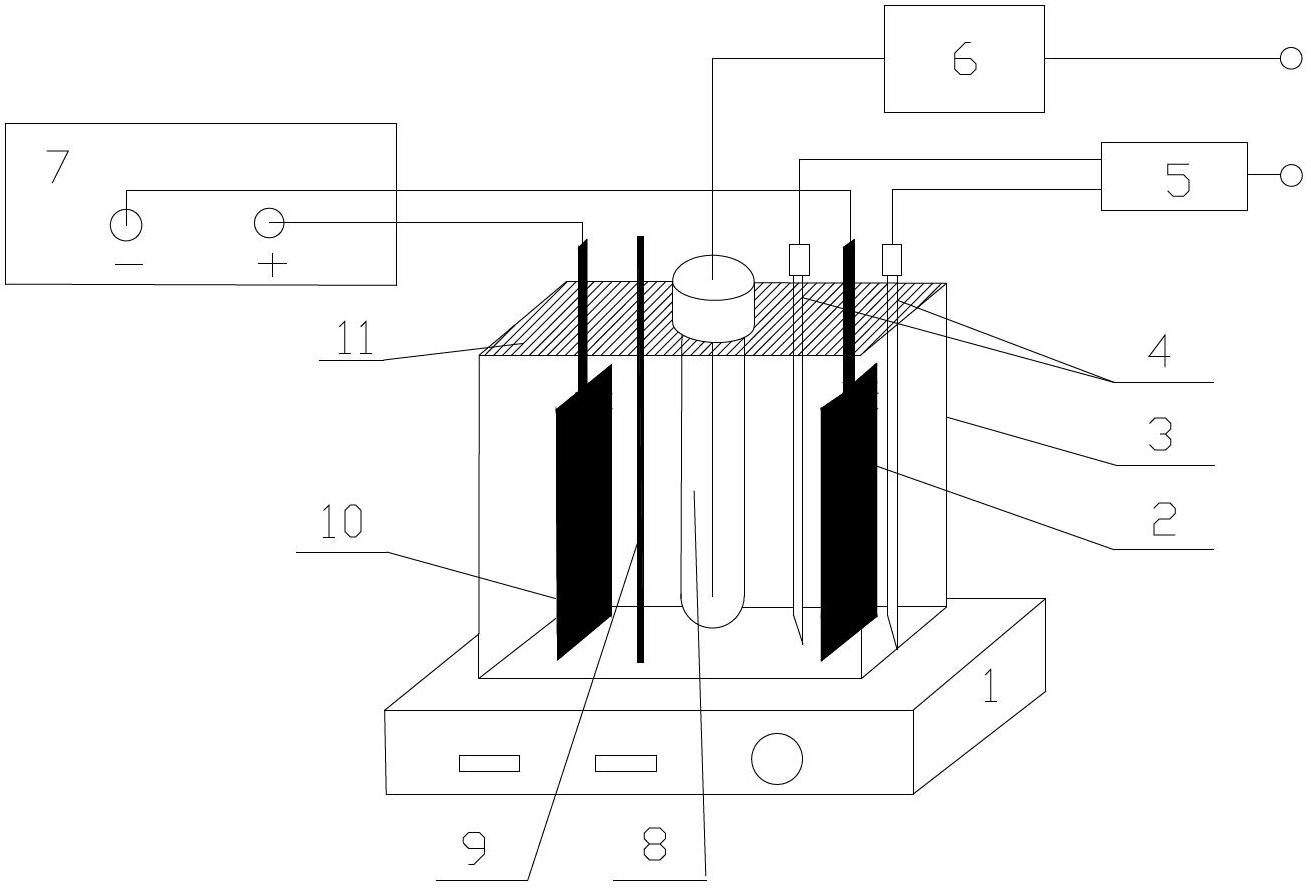

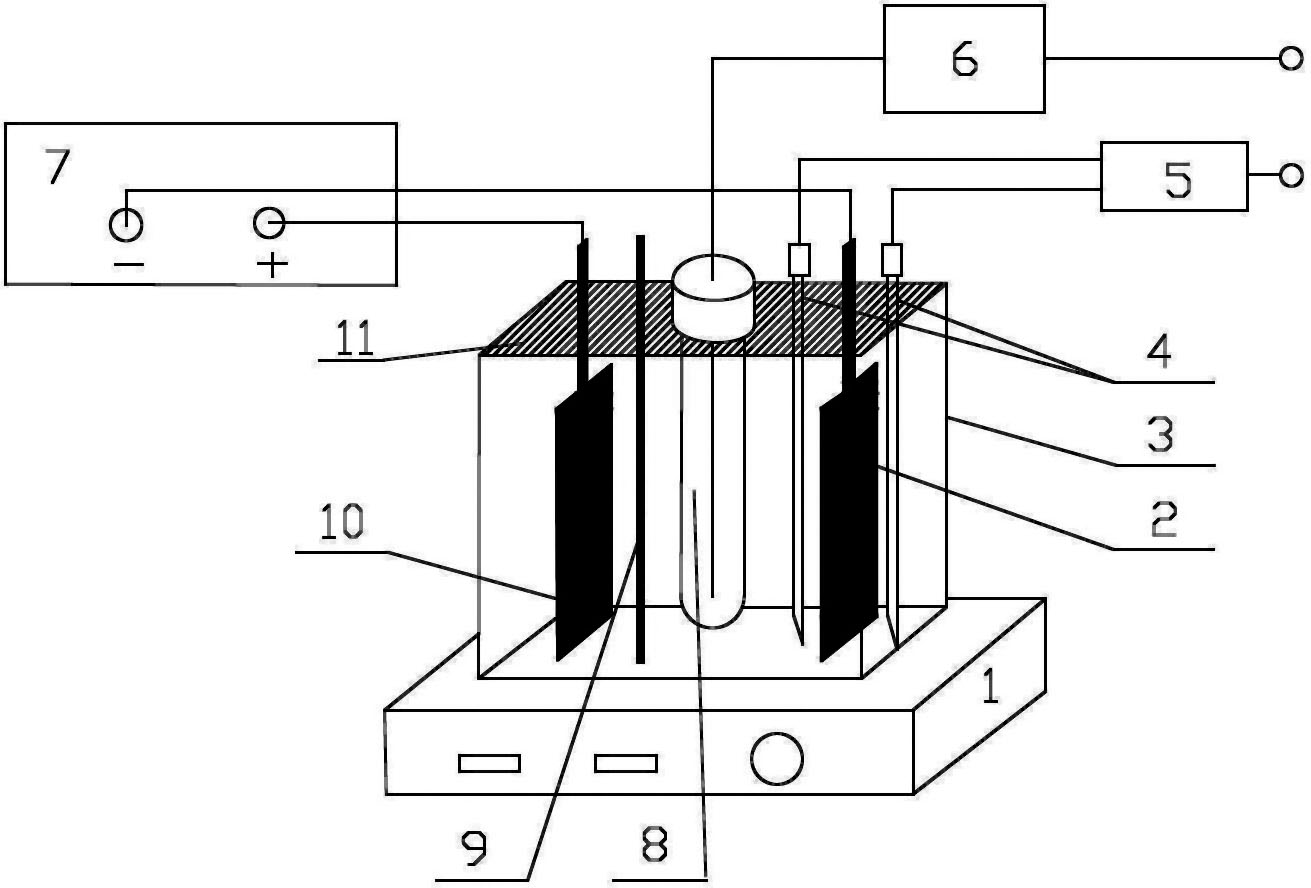

[0017] A photo / electrical Fenton device for treating refractory organic wastewater, its schematic diagram is as follows figure 1 As shown, it includes: magnetic stirrer 1, cathode 2, electrolytic tank 3, aeration tube 4, aerator 5, lamp ballast 6, DC constant current and voltage supply 7, ultraviolet lamp 8, iron electrode 9 , anode 10, baffle 11. The electrolytic tank is a reaction tank with an open top, which is the main structure of the photoelectric Fenton device, and the electrolytic tank is placed on a magnetic stirrer.

[0018] The anode of the device adopts Ti / Pt electrode, the cathode adopts ACF electrode, and the activated carbon fiber cloth is wrapped on the metal iron plate. On both sides, the specific surface area of the activated carbon fiber is large, and more oxygen in the solution generates hydrogen peroxide on the cathode. The length and width of the electrode plate are determined according to the width and height of the electrolytic cell.

[0019] The tw...

Embodiment 2

[0025] Configure 3000mg / L of polyvinyl alcohol simulated desizing wastewater, take 750mL of wastewater and adjust the pH value to 6 with a mass concentration of 40% dilute sulfuric acid, and add 10.0‰ (accounting for the mass percentage concentration of polyvinyl alcohol simulated desizing wastewater) Seven After hydrating ferrous sulfate powder, this photoelectric Fenton device is used. The size of the electrolytic cell is 200mm×110mm×120mm, and the anode is a Ti / Pt electrode, and the size is 60mm×110mm×0.5mm. The cathode is ACF, the electrode uses viscose-based activated carbon fiber, and the specific surface area is 1300m 2 / g, cut it to the same size as the anode, wind it on the inert Ti electrode, and aerate the cathode with an aerator. The electrode is powered by a DC-type constant current and voltage stabilized power supply, and the constant voltage current is adjusted to 2.5A. Turn on the magnetic stirrer with a rotating speed of 1000r / min. Insert an ultraviolet lamp...

Embodiment 3

[0027] The polyether wastewater of a petrochemical company in Shanghai has low B / C and poor biochemical properties. The wastewater volume is 1500mL, the size of the electrolytic cell is 400mm×220mm×240mm, the size of the cathode and anode is 120mm×110mm×0.5mm, and the cathode is ACF The electrode is made of viscose-based activated carbon fiber with a specific surface area of 1400m 2 / g, the electrode plate spacing is 8cm, the constant voltage current is 1.5A, add 8.0‰ (accounting for the mass percentage concentration of polyether wastewater) ferrous sulfate heptahydrate powder, and adjust the pH to 4 with 30% hydrochloric acid. The speed of the magnetic stirrer is 800r / min, the power of the ultraviolet lamp is 8w, the aeration rate of the aerator is 2.5L / min, and the iron rod with a diameter of 5mm is inserted under the experimental conditions, and the photoelectric Fenton reaction is carried out for 120min. COD in glyphosate wastewater Cr The removal rate reached 65.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com