Ammonium fluoride wastewater treatment technique

A technology for wastewater treatment and ammonium fluoride, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, etc., can solve the problems of slow reaction speed and low treatment cost, Achieve the effects of reduced adsorption, high water flux, and increased width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

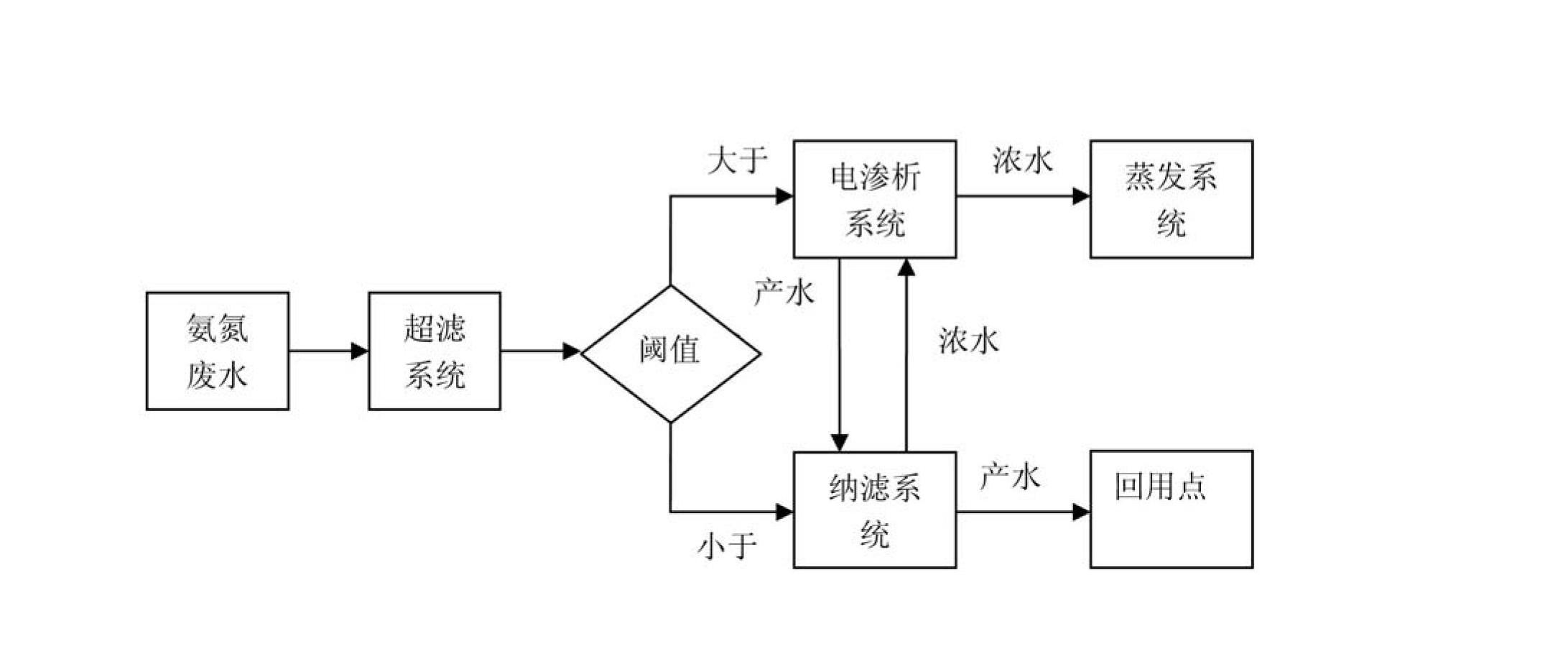

[0035] will be 2m 3 / d. After the wastewater with a concentration of 0.2% ammonium fluoride is collected by the raw water tank, adjust the pH value to 6. The ammonium fluoride wastewater with stable physical and chemical properties is sent to the ultrafiltration system for removal of suspended solids. The membrane modules of the ultrafiltration system use hollow fiber membranes, and the material of the ultrafiltration membrane is polypropylene; When the concentration reaches 8mg / L, it enters the nanofiltration system for concentration and desalination. The membrane module of the nanofiltration system adopts a coiled membrane module, and the material of the nanofiltration membrane is polyamide; when the pH value is 6 and the concentration of the concentrated solution is 2%, it enters the electrodialysis system after being concentrated and desalted by the first-level nanofiltration. In the electrodialysis system, after treatment, part of the wastewater is desalinated and part o...

Embodiment 2

[0037] will be 3m 3 / d. After the ammonium fluoride wastewater with a concentration of 12% is collected by the raw water tank, the pH value is adjusted to 9, and the ammonium fluoride wastewater with stable physical and chemical properties is sent to the ultrafiltration system for removal of suspended solids. The membrane module of the ultrafiltration system adopts hollow fiber membranes, and the material of the ultrafiltration membrane is polyvinylidene fluoride. When the concentration of suspended solids in the ammonium fluoride wastewater is treated to 3mg / L, it enters the electrodialysis system for concentration and desalination. Treatment is carried out in an electrodialysis system. After treatment, part of the wastewater is desalinated and part of the wastewater is concentrated. When the ammonium fluoride concentration of the desalinated wastewater is 0.3%, it enters the nanofiltration system with good anti-pollution performance and high rejection rate for further desali...

Embodiment 3

[0039] will be 4m 3 / d. After the ammonium fluoride wastewater with a concentration of 3% is collected by the raw water tank, the pH value is adjusted to 7, and the ammonium fluoride wastewater with stable physical and chemical properties is sent to the ultrafiltration system for removal of suspended solids. The membrane module of the ultrafiltration system adopts hollow fiber membranes, and the material of the ultrafiltration membrane is polyethersulfone; when the concentration of suspended solids in the ammonium fluoride wastewater is treated to 5mg / L, it enters the electrodialysis system for concentration and desalination. Treatment is carried out in an electrodialysis system. After treatment, part of the wastewater is desalinated and part of the wastewater is concentrated. When the concentration of ammonium fluoride in the desalinated wastewater is 0.2%, it enters the nanofiltration system with good anti-pollution performance and high rejection rate for further desalinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com