Method for extracting and refining anthocyanin in black rice

A technology of extraction method and purification method, applied in chemical instruments and methods, preparation of sugar derivatives, antidote and other directions, can solve the problems of backward production technology of black rice anthocyanins, unfavorable large-scale production, low product purity, etc. Coronary heart disease incidence, improved visual acuity, and improved product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

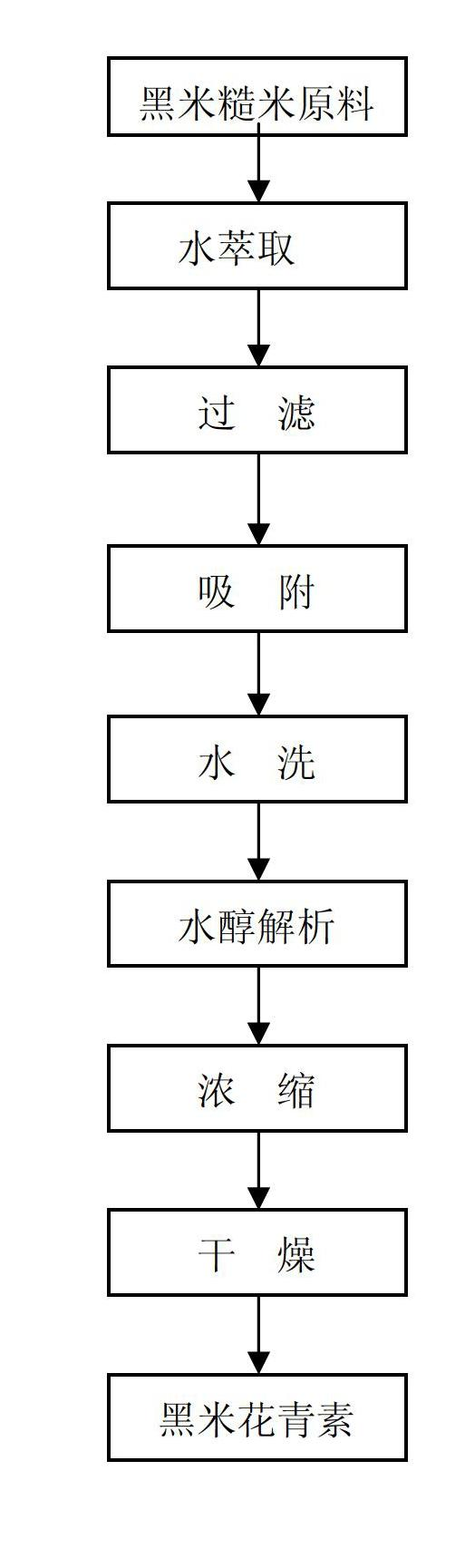

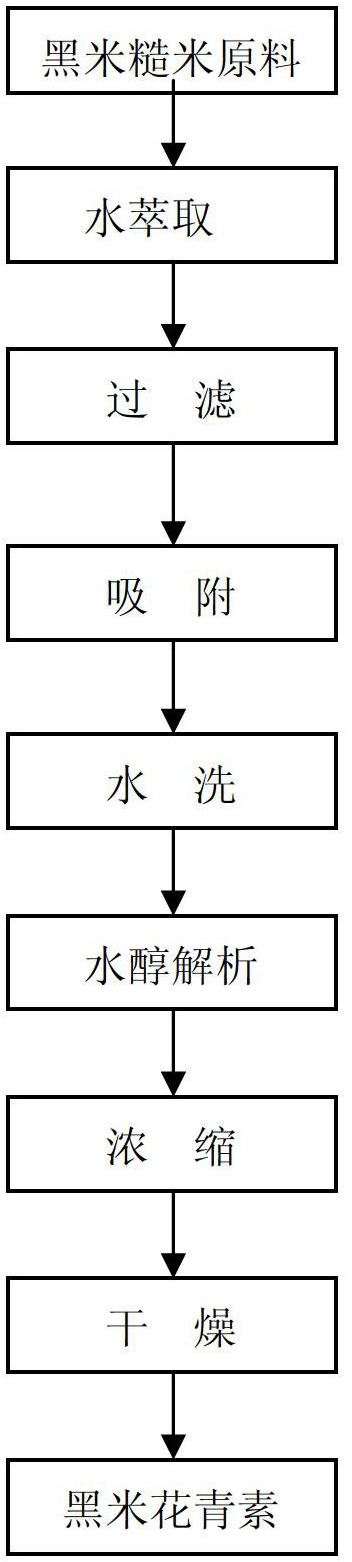

[0029] The embodiment of the present invention comprises the following steps:

[0030] (1) Black rice and brown rice or black rice and brown rice bran are added with an acid-containing aqueous solution for heat preservation and extraction, filtered to obtain an extract, and the extract and raw materials are retained; the extraction process can be repeated 2-5 times. The acid used for extraction is an inorganic acid or an organic acid, which can be one or more mixtures of hydrochloric acid, sulfuric acid, phosphoric acid, acetic acid, citric acid, gallic acid, tartaric acid, propionic acid, butyric acid, valeric acid or oxalic acid. The extraction temperature is 30-70°C.

[0031] (2) The water extract is adsorbed by a macroporous adsorption resin; after washing with water, the macroporous adsorption resin is a non-polar or weakly polar resin, specifically D101, D201, AB-8, XAD-6, XAD Any of -7, XAD-10, MD21, LD-305.

[0032] (3) After the macroporous adsorption resin is washe...

example 1

[0037] Example 1: Take 1kg of black rice and brown rice, add 6 times the amount of acid water (hydrochloric acid to adjust the pH to 1.5-1.8), keep warm at 45-50°C for 1 hour, filter, add 2 times the amount of acid water to rice dregs, and keep warm at 45-50°C After 30 minutes, filter, combine the two extracts, pass through D101 macroporous adsorption resin column, wash with deionized water until the color of the effluent is light, then analyze with 10-80% ethanol, and concentrate the solution under reduced pressure to a relative density of 1.0-1.2 , spray-dried at 180°C to obtain 10.3g of anthocyanins, the yield was 1.03% of the weight of the raw material, and the anthocyanin content was 32.2%.

example 2

[0038] Example 2: Take 1kg of black rice and brown rice, add 8 times the amount of acid water (adjust pH 1.8-2.2 with sulfuric acid), keep warm at 60°C for 1 hour, filter, add 2 times the amount of acid water to the rice dregs, keep warm at 60°C for 1 hour, and filter , combine the two extracts, pass through the XAD-7 macroporous adsorption resin column, wash with pure water until the color of the effluent is light, then analyze with 10-80% ethanol, concentrate the analysis solution under reduced pressure to a relative density of 1.0-1.2, 150°C Spray-dried to obtain 9.7 g of anthocyanins, the yield rate was 0.97% of the raw material weight, and the anthocyanin content was 26.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com