Method for preparing flexible optical detector on basis of two-dimensional functional material

A photodetector and functional material technology, applied in the field of preparation of photodetectors, can solve the problems of difficult mass production and high cost of photolithography technology, and achieve high-density integration, good light transmission and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Embodiment 1: A method for preparing a flexible photodetector based on two-dimensional functional materials in this embodiment is carried out in the following steps:

[0026] 1. Synthesize semiconductor material single crystal gallium selenide or single crystal gallium sulfide by high temperature reaction in tube furnace;

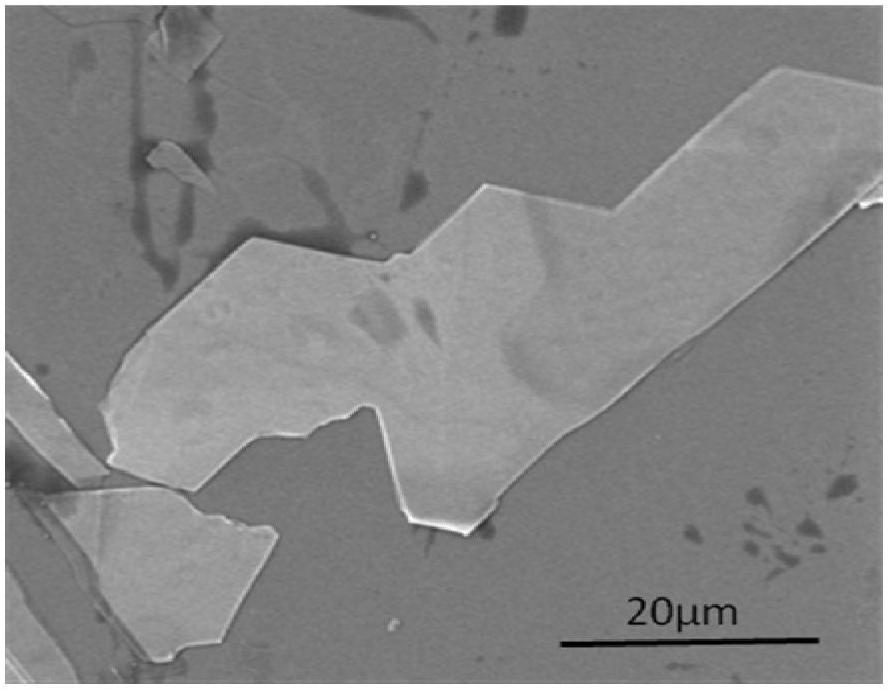

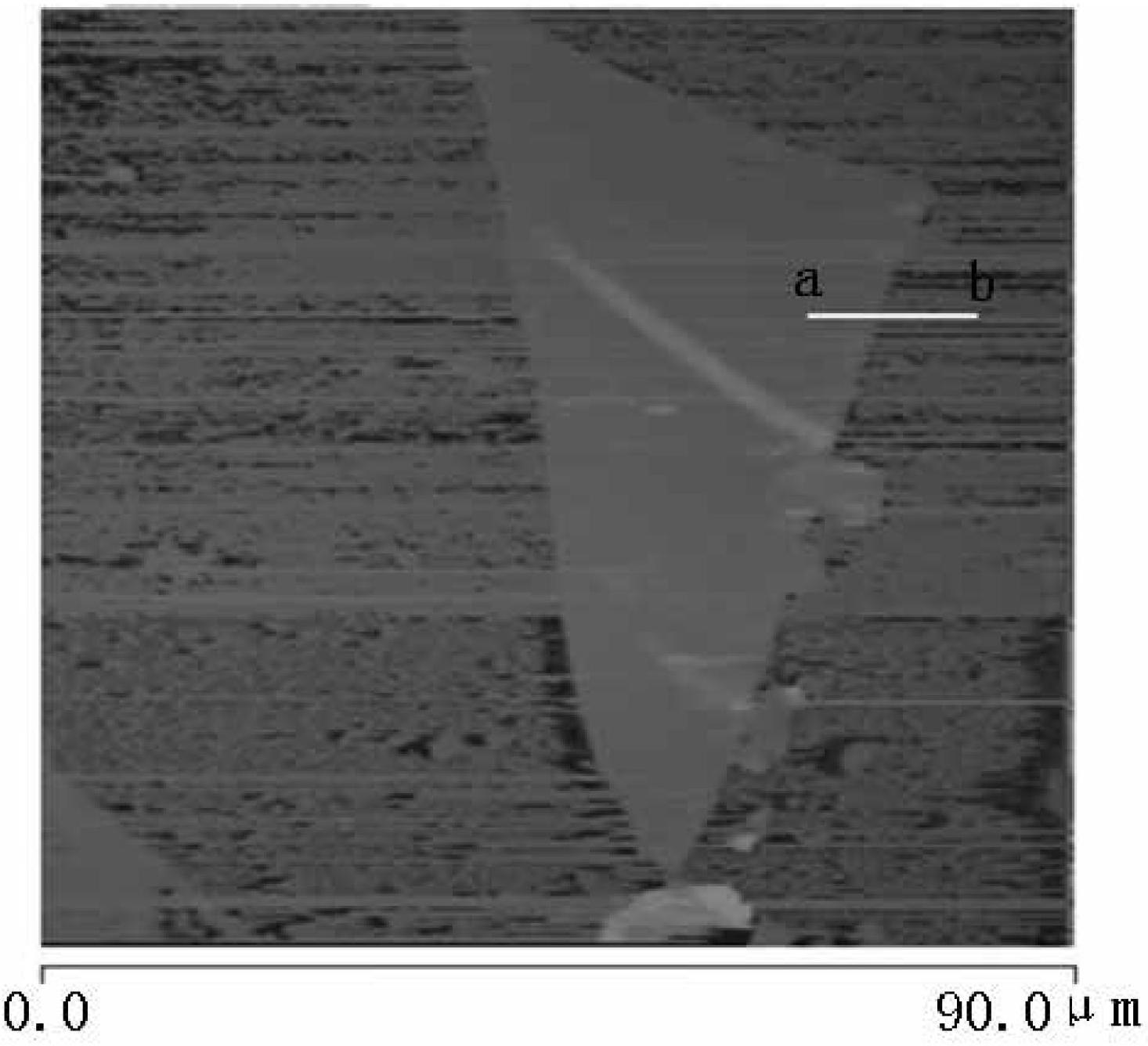

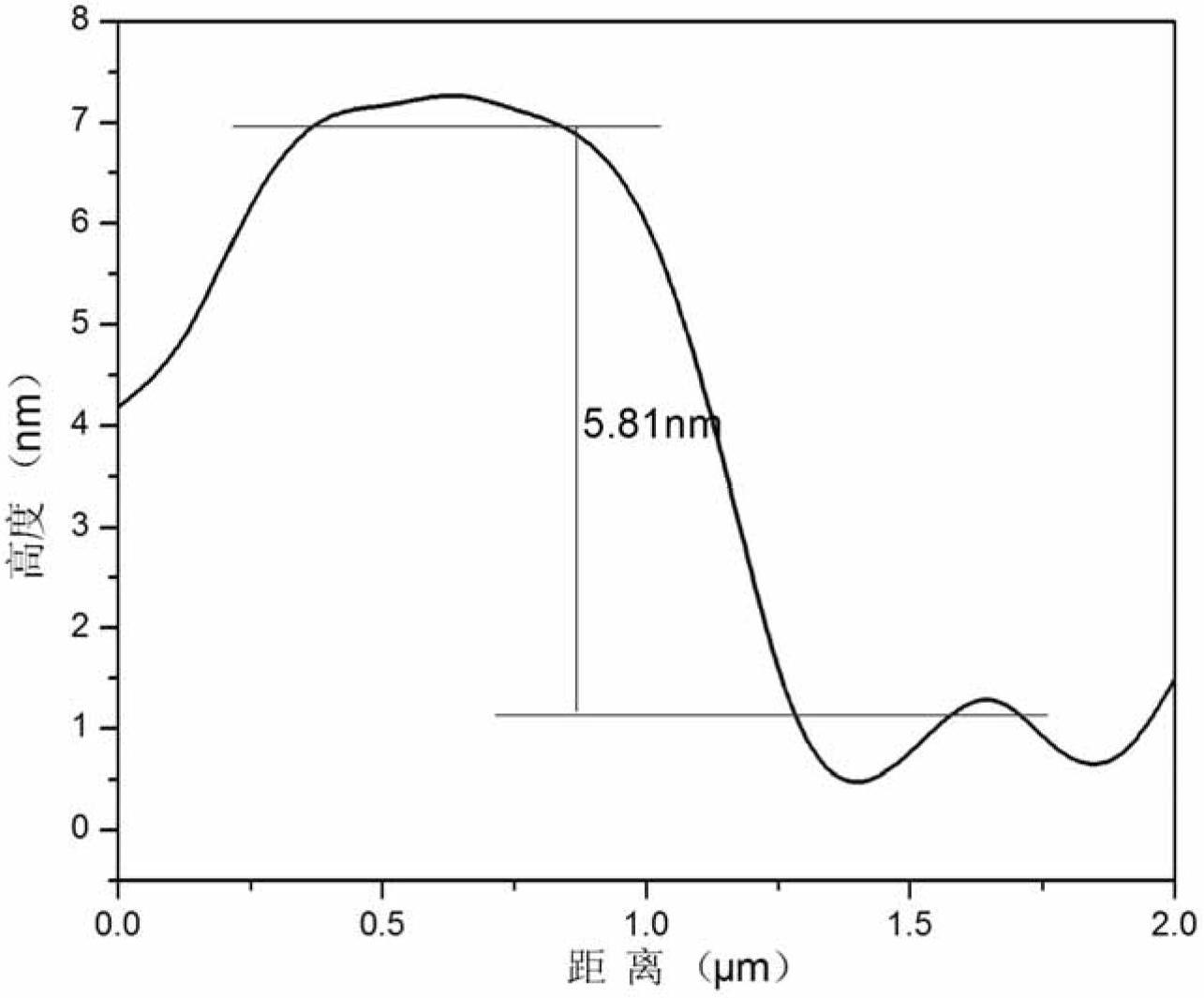

[0027] 2. Use Scotch tape to paste on the surface of the semiconductor material prepared in step 1—peel off 5 to 50 times to obtain a two-dimensional structure semiconductor material adhered to the Scotch tape;

[0028] 3. After cleaning the polyethylene terephthalate film substrate, stick the Scotch tape with the two-dimensional structure semiconductor material adhered to the polyethylene terephthalate plastic substrate obtained in step 2, and gently press it out The air bubbles between the tape and the substrate, after standing for 1 to 10 minutes, tear off the Scotch tape, wash the substrate with ethanol to remove the residual offset printing, and...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of single crystal gallium selenide in step one is as follows: A, the molar ratio of gallium and selenium is 1: (1.3~2) and weighs analytical pure Gallium powder and analytically pure selenium powder are placed together in a tube furnace, wherein the selenium powder is located in the low temperature zone of the tube furnace, and the gallium powder is located in the high and low temperature zone of the tube furnace, and the gas flow rate is 10-30 sccm normal pressure argon Gas, the flow direction of argon is from the low-temperature area to the high-temperature area; B. Raise the temperature of the low-temperature area to 400-600 °C, and at the same time raise the temperature of the high-temperature area to 1000-1050 °C, and the selenium vapor contacts with the gallium along with the flow of argon gas And react, the reaction time is 30-45min; then the ...

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the preparation method of single crystal gallium sulfide in step one is as follows: A, the molar ratio of gallium and sulfur is 1: (1.3~2) and weighs analytical pure gallium Powder and analytically pure sulfur powder are placed together in a tube furnace, wherein the sulfur powder is located in the low temperature zone of the tube furnace, and the gallium powder is located in the high and low temperature zone of the tube furnace, and the gas flow rate is 10-30 sccm normal pressure argon. , the flow direction of the argon is from the low temperature zone to the high temperature zone; B. Raise the temperature of the low temperature zone to 300-350°C, and at the same time raise the temperature of the high temperature zone to 1000-1050°C, the sulfur vapor comes into contact with the gallium along with the argon gas flow and A reaction occurs, and the reaction time is 30-45 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com