Preparation method of potassium-containing round-tungsten-doped aluminum strip

A potassium-doped, tungsten-aluminum technology is applied in the field of preparation of high-purity, dense, and special tungsten materials. It can solve the problems of poor normal powder distribution, poor product performance, and low density, and achieve fine and uniform cross-sectional crystallization. Good anti-sag performance and evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

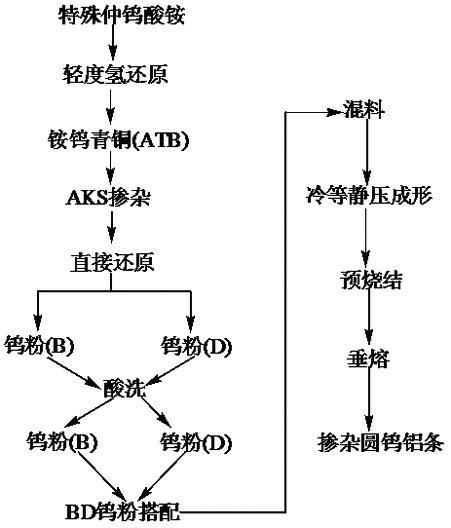

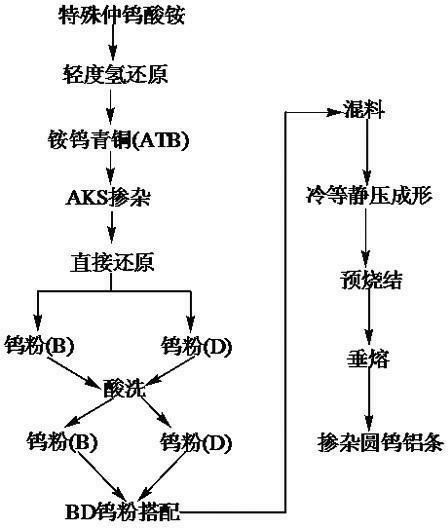

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing potassium-doped round tungsten-aluminum rods, comprising the following steps:

[0024] 1. Material selection: choose Fibonacci particle size of 43.5μm, bulk density of 2.32g / cm 3 The crystalline form of ammonium paratungstate is used as raw material, and its sieve analysis requirements are: +150 mesh (≥105μm): 27.76%; -150~+200 mesh (-105~+75μm): 27.35%; -200~+250 mesh (-75~ +58μm): 7.65%; -250~+325 mesh (-58~+45μm): 22.76%; -325 mesh (≤-45μm): 14.48%;

[0025] 2. Mild hydrogen reduction: the above-mentioned raw materials are subjected to mild hydrogen reduction using a seven-zone temperature zone reduction furnace, the temperature is 300, 360, 400, 420, 430, 450, 420 °C, and the hydrogen flow rate is 0.2m 3 / h, hydrogen dew point ≤ -60°C, boat load of 430g, pushing speed of 15min, resulting Fischer particle size of 9.8μm, NH 3 Special intermediate ammonium tungsten bronze (ATB) with a content of 0.8%;

[0026] 3. AKS doping: ATB wet doping wit...

Embodiment 2

[0035] A method for preparing potassium-doped round tungsten-aluminum rods, comprising the following steps:

[0036] 1. Material selection: choose Fibonacci particle size of 48.9μm, bulk density of 2.45g / cm 3 The crystalline form of ammonium paratungstate is used as raw material, and its sieve analysis requirements are: +150 mesh (≥105μm): 24.37%; -150~+200 mesh (-105~+75μm): 31.65%; -200~+250 mesh (-75~ +58μm): 6.77%; -250~+325 mesh (-58~+45μm): 22.45%; -325 mesh (≤-45μm): 14.76%;

[0037] 2. Mild hydrogen reduction: The above-mentioned raw materials are subjected to mild hydrogen reduction using a seven-zone temperature zone reduction furnace, the temperature is 300, 360, 400, 420, 430, 450, 420 °C, and the hydrogen flow rate is 0.3m 3 / h, hydrogen dew point ≤ -60°C, boat load of 420g, pushing speed of 15min, resulting Fischer particle size of 10.5μm, NH 3 Special intermediate ammonium tungsten bronze (ATB) with a content of 0.85%;

[0038] 3. AKS doping: ATB wet doping w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com