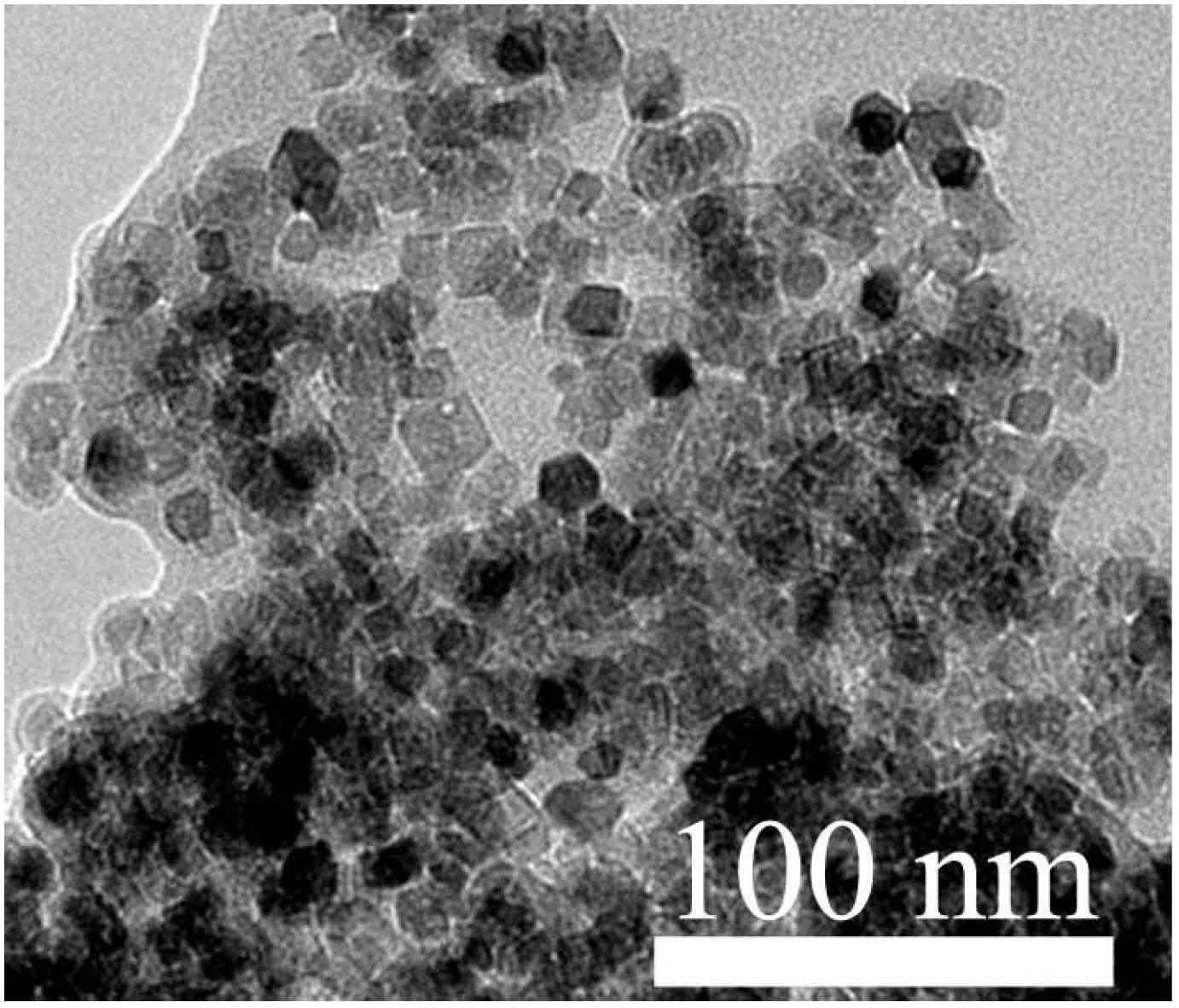

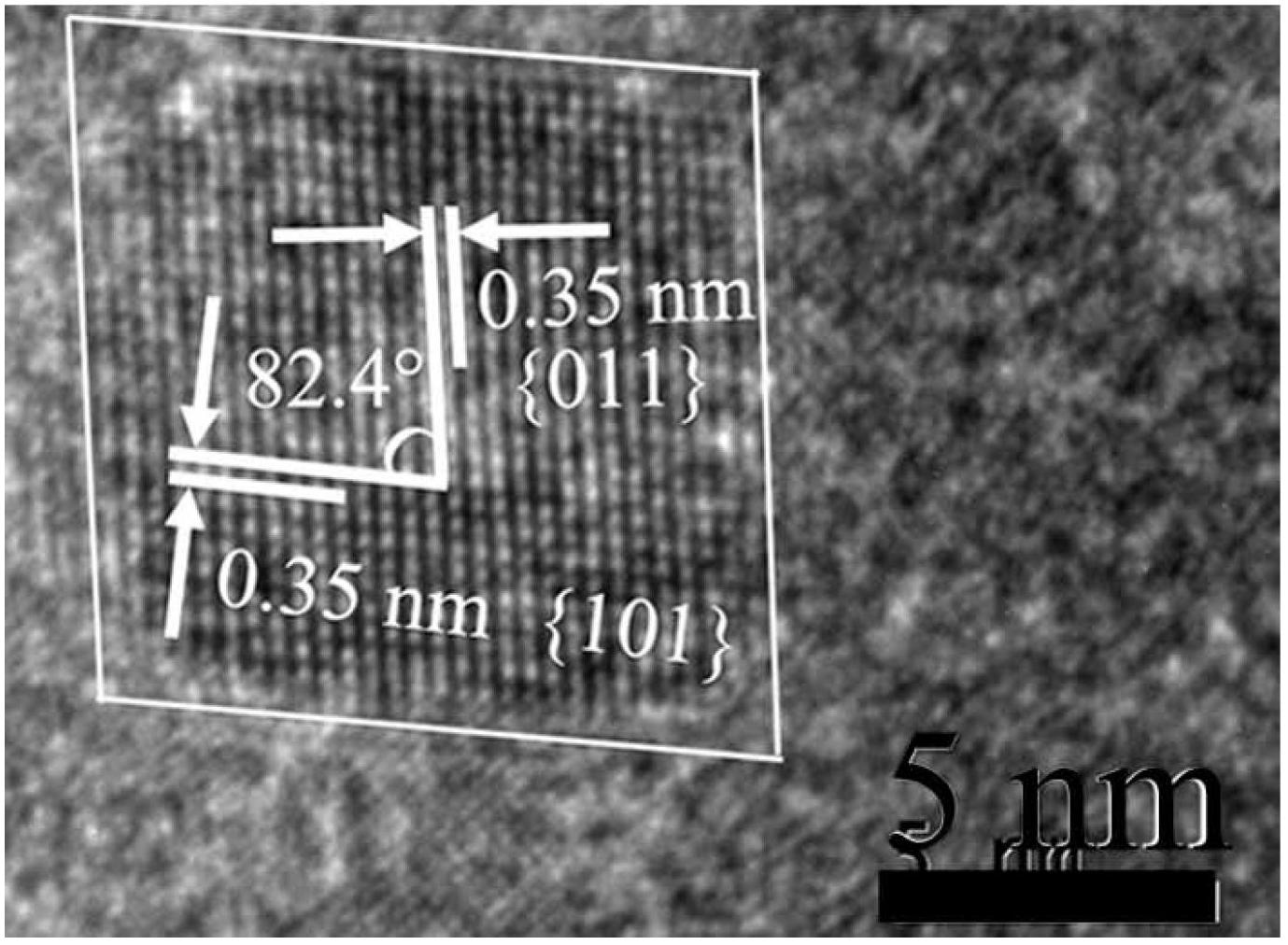

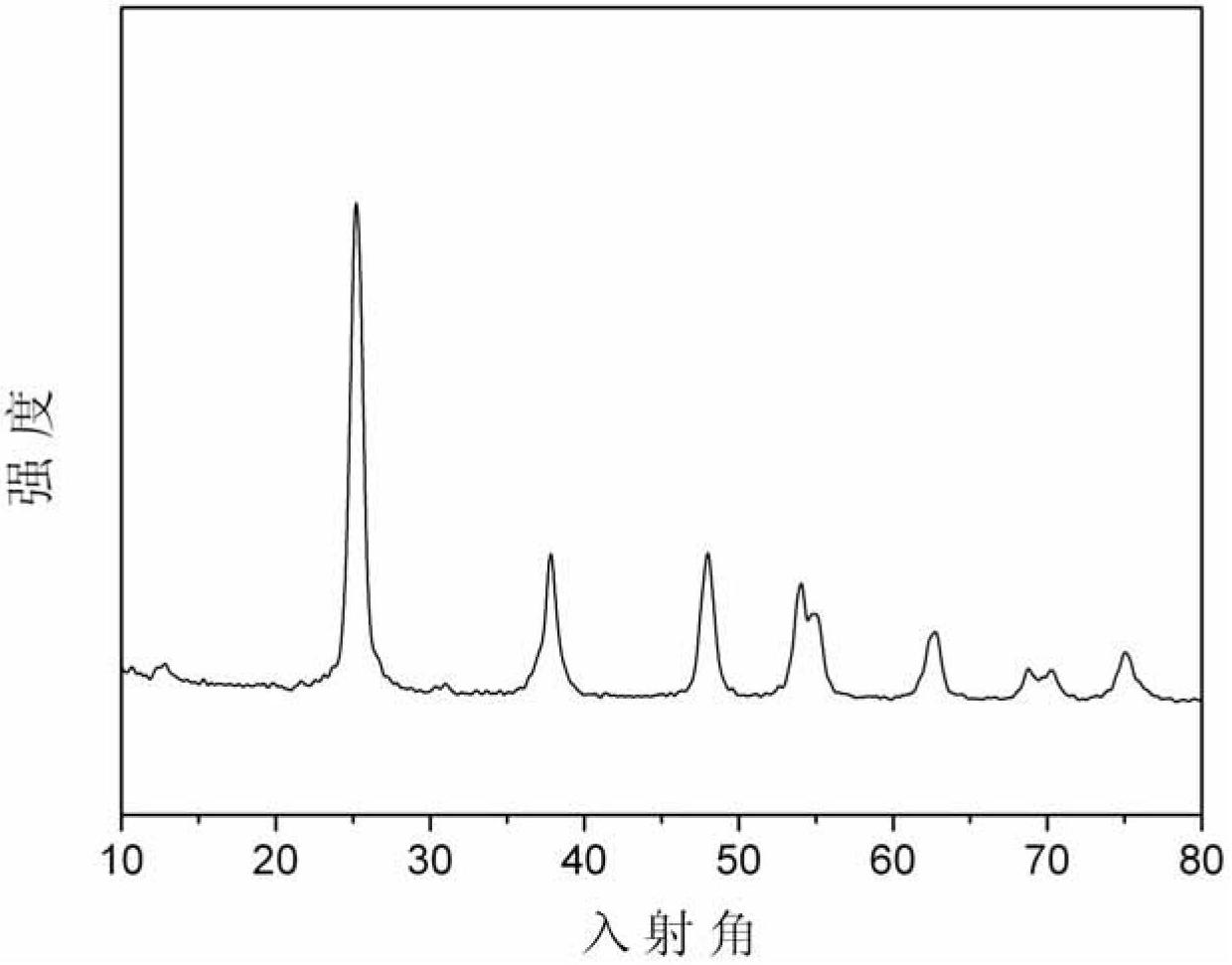

Preparation method of {001} face exposed titanium dioxide nanocrystals

A titanium dioxide and nanocrystal technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of large particle size and small specific surface area of titanium dioxide nanocrystals, and achieve simple equipment and process, and cheap and easy raw materials. obtainable, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode 1: In this implementation mode, a method for preparing titanium dioxide nanocrystals exposed on the {001} surface, the specific steps are as follows:

[0028] 1. Add titanium salt to ethanol or isopropanol to prepare 50mL-100mL alcohol solution with a concentration of 0.1mol / L-0.5mol / L;

[0029] 2. Drop the alcohol solution prepared in Step 1 into 60mL-120mL deionized water under stirring conditions, and then stir for 30 minutes at a stirring speed of 300-1000 rpm at a water bath temperature of 60°C-90°C ~100 minutes, add 50mL~300mL of 0.5mol / L~5.0mol / L alkali solution, seal it, then continue to stir at 60℃~90℃ for 4 hours~12 hours, centrifuge to separate the white precipitate, and wash the white precipitate with deionized water Precipitate for 3 to 5 times until the pH value of the supernatant is neutral to obtain protonated hydrated titanic acid;

[0030] 3. Wash the protonated hydrated titanic acid with alcohol for 3 to 5 times, then tra...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium salt described in Step 1 is titanium tetrachloride, titanium sulfate, titanium oxysulfate, butyl titanate or isopropyl titanate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the alkali solution described in step 2 is sodium hydroxide solution, potassium hydroxide solution or sodium carbonate solution. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com