Nitrified sludge efficient enriching culture system based on membrane bioreactor and method

A membrane bioreactor and enrichment culture technology, which is applied in the field of high-efficiency enrichment and culture systems for nitrification sludge, can solve the problems of unfavorable continuous enrichment, continuous addition, sudden change in ammonia nitrogen load, and high cost of centrifugal fermentation, reducing construction volume and reducing costs. The effect of enrichment time, cost savings, and enhanced nitrification enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

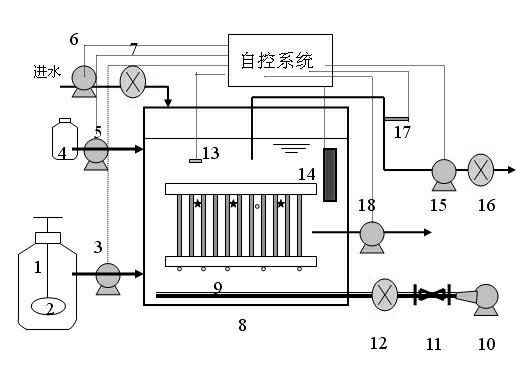

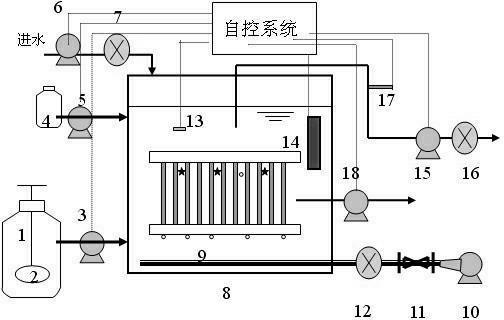

Image

Examples

Embodiment 1

[0034] A municipal sewage treatment plant adopts A 2 / O treatment process, the treated water volume is 25,000 m 3 / d, the effective volume of the aerobic pool is about 7000m 3 , the concentration of ammonia nitrogen in the influent and effluent water is 50mg / L and 15mg / L respectively, and the nitrification activity is 120mgN / L·d. Now the ammonia nitrogen in the effluent is reduced to 5mg / L, which meets the national "Urban Sewage Treatment Plant Pollutant Discharge Standard" (GB18918-2002) Class A discharge standard. The volume of construction near the sewage treatment process (main process) is 310m 3 The bypass system (accounting for about 4.5% of the main process volume) implements continuous enrichment of nitrifying bacteria and continuous dosing to the main process.

[0035] The bypass system is inoculated with the activated sludge of the sewage plant, the initial MLSS is controlled at 5g / L, and it operates in a completely mixed continuous water inlet and outlet mode. E...

Embodiment 2

[0038] A sewage treatment plant in an industrial park with a treatment volume of 10,000 m 3 / d, using hydrolytic acidification-aerobic activated sludge treatment process, the effective volume of the aerobic pool is 10,000 m 3 . Affected by the wastewater discharge of network-connected enterprises in the park, the quality and quantity of influent water vary greatly, which often has a great impact on the activated sludge system, resulting in the collapse of the nitrification function. It often takes more than two months to restore the nitrification performance, and the cycle is long. Seriously affected the stable and up-to-standard discharge of the treated effluent of the sewage plant. Build an effective volume of 450m near the aerobic pool in the sewage plant 3 The nitrifying bacteria bypass enrichment system (4.5% of the effective volume of the aerobic section) is inoculated with the main process activated sludge, the initial MLSS is controlled at 5g / L, and it operates in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com