Mobile integrated sludge anaerobic acidification liquid denitrification and dephosphorization treatment device

An anaerobic acidification, nitrogen and phosphorus removal technology, applied in the field of water pollution treatment, can solve the problems of easy release under anaerobic conditions, large sludge output, etc., and achieves a small footprint, flexible use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

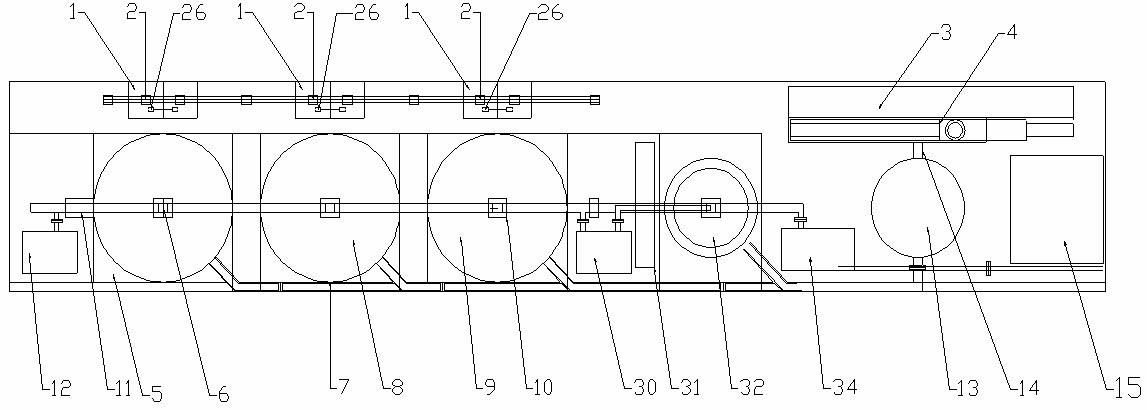

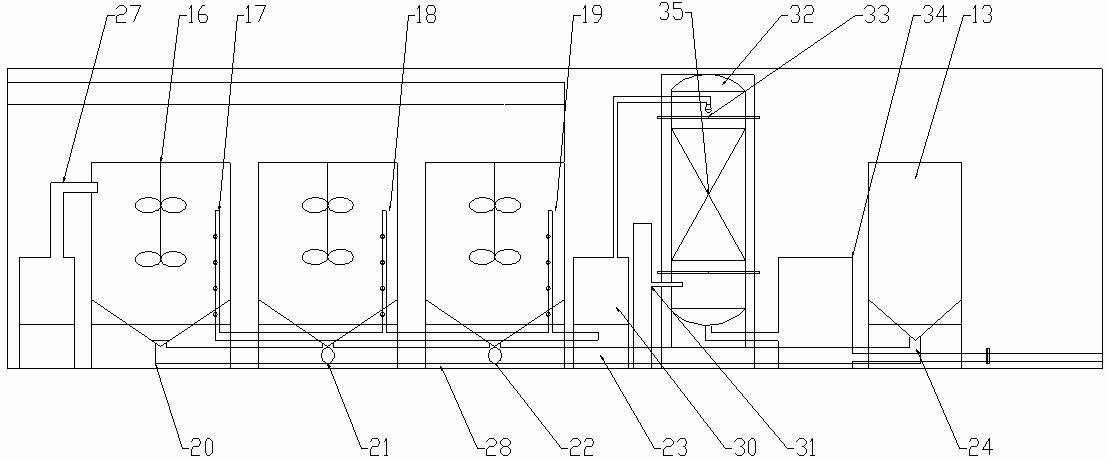

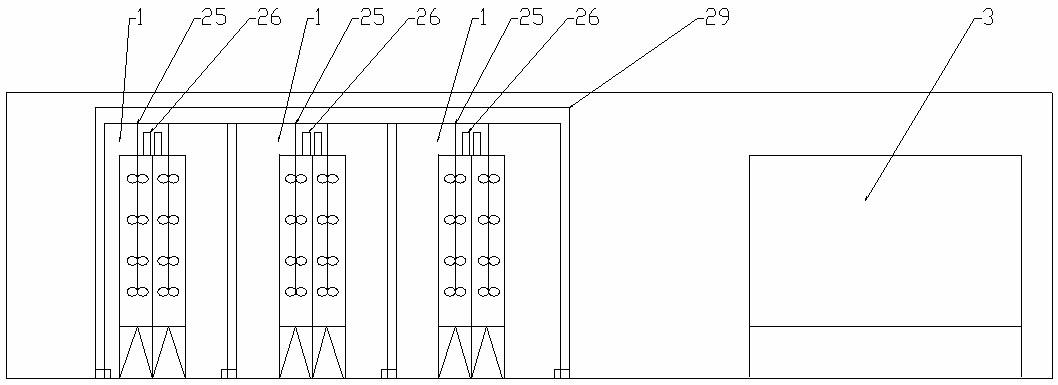

[0030]The capacity of this device to treat sludge anaerobic acidification liquid is 6 tons / day. The main design parameters and dimensions of the device are as follows:

[0031] The size of the whole container is 11.8m×2.13m×2.72m. The material of the dosing tank 1 is plastic, and the size is 0.37m×0.37m×2.12m. The tap water pipe of the dosing tank is made of UPVC material, DN20mm. The pH adjustment tank 5, the coagulation sedimentation tank 7, and the aeration tank 9 have the same structure and are all made of plastic, with a size of Φ1.2m and a height of 1.87m. Maximum volume 2.60m 3 . The water inlet pipe 27 is a Φ0.4m UPVC pipe. The mud discharge pipe 28 adopts UPVC pipe, DN80mm. After the acidification solution enters the first pH adjustment tank, it enters the coagulation sedimentation tank 7 through the lift pump, and CaO is added to react with TP in the wastewater to form a small precipitate suspension. The molar dosage of CaO is equivalent to 1.6 times the molar c...

Embodiment 2

[0034] The structure of the device is the same as in Example 1, and the device obtained is used to process the sludge acidification solution of a certain urban sewage plant, and the water quality parameter SCOD of the anaerobic acidification solution is Cr 7210 mg / L, NH 3 -N 440 mg / L, T-N 492 mg / L, SOP 111.9 mg / L, TP 129.5 mg / L. NH in acidified solution after treatment 3 The removal rate of TN content is less than 10mg / L, and the removal rate is over 95%; the removal rate of TN content is 17mg / L; the removal rate is over 90%; SOP 3mg / L; T-P 5mg / L; COD content 5211mg / L. The carbon-nitrogen ratio and carbon-phosphorus ratio are 659 and 1042 respectively, so the acidification solution is suitable as an additional carbon source for nitrogen removal in sewage treatment plants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com