Preparation method for high-density PbSe quantum dot silicate glass

A technology of silicate glass and quantum dots, which is applied in the fields of optical communication technology and nanomaterial preparation, can solve the problems of easy volatilization of elemental Se components, and achieve the effects of low price, increased content, and avoidance of high temperature volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Glass matrix formula chooses SiO 2 , B 2 o 3 、Al 2 o 3 , ZnO, AlF 3 and NaO 2 , choose PbO and ZnSe as the precursor of PbSe quantum dots, the mass fraction ratio is: SiO 2 :B 2 o 3 :Al 2 o 3 :ZnO:AlF 3 : NaO 2 :PbO:ZnSe=56.50%:4.33%:3.85%:8.57%:2.12%:15.11%:5.78%:3.74%. Weigh raw material SiO 2 : 56.50g; B 2 o 3 : 4.33g; Al 2 o 3 : 3.85g; ZnO: 8.57g; AlF 3 : 2.12g; NaO 2 ZnSe: 15.11g; PbO: 5.78g; ZnSe: 3.74g, put the above chemical raw materials in a ball mill and stir evenly, take them out and put them in a closed corundum crucible, then put them in a box-type electric furnace, melt at 1400 °C for 1 hour, and then The melt was poured onto a metal mold, cooled rapidly to room temperature, and yellow glass was obtained.

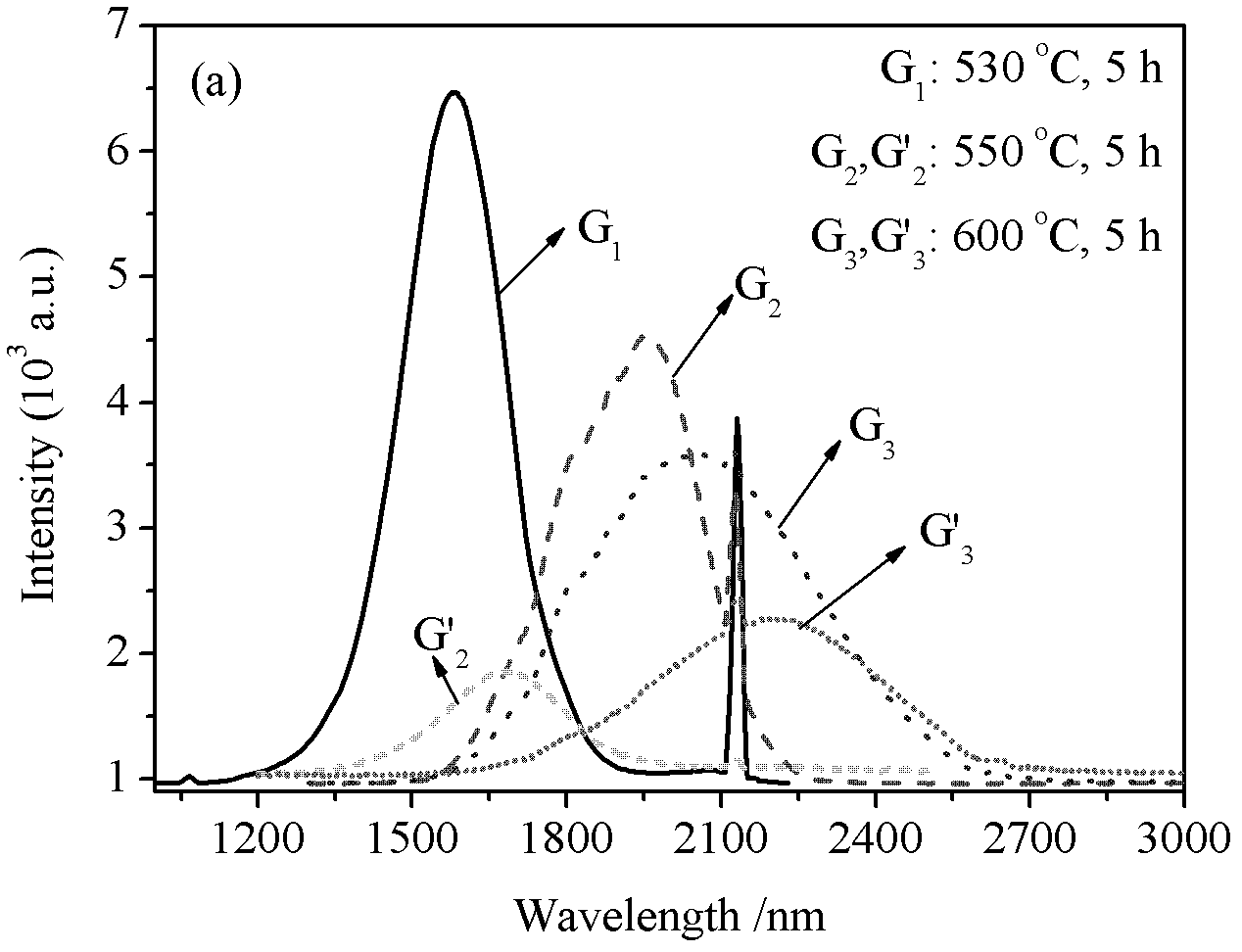

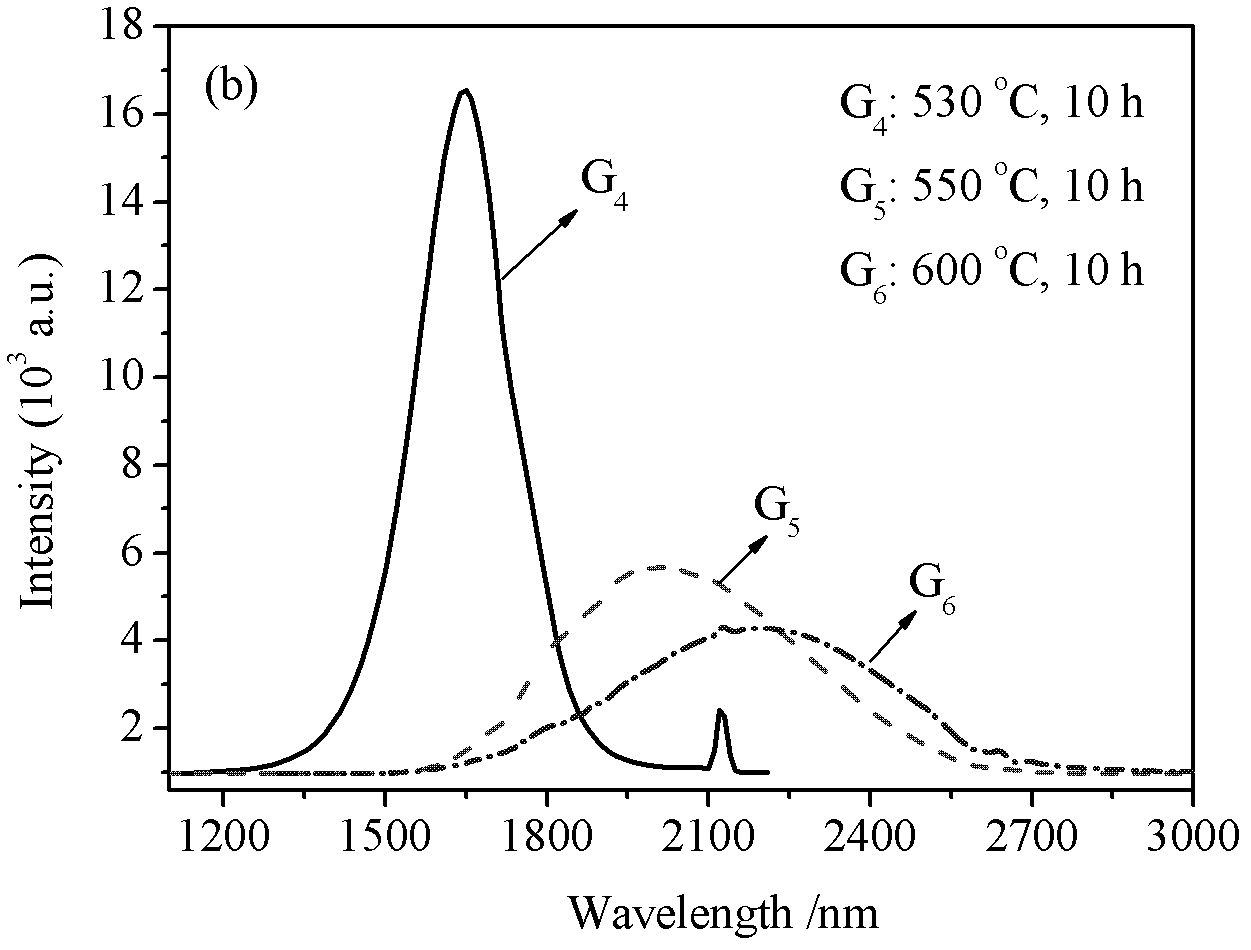

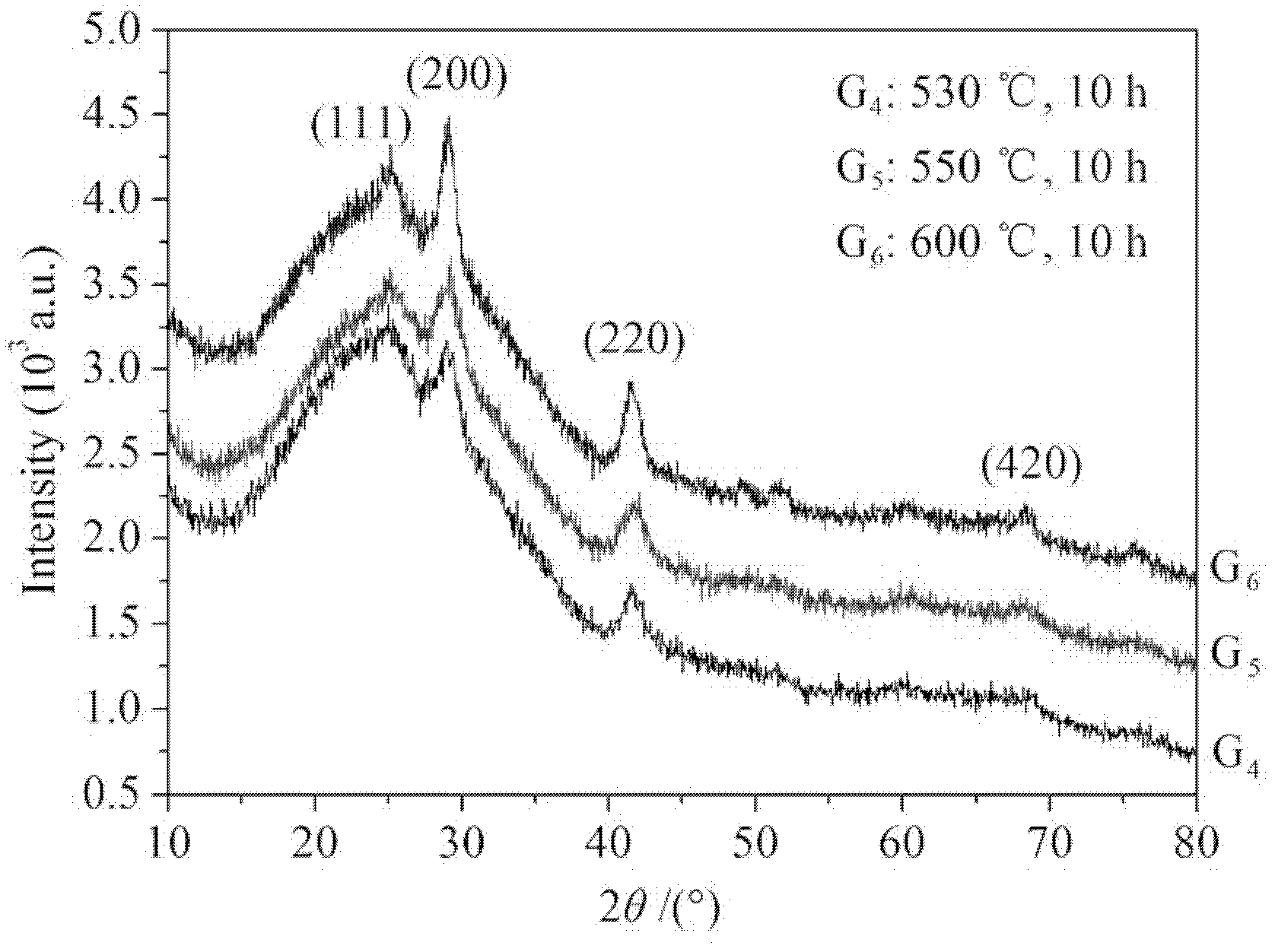

[0028] Then put the glass into a box-type electric furnace, heat-treat at 530°C for 5h, take it out and cool it to room temperature in the air, and obtain a pure black PbSe quantum dot silicate glass sample (denoted as G 1 ). Acco...

Embodiment 2

[0030] Glass matrix formula chooses SiO 2 , B 2 o 3 、Al 2 o 3 , ZnO, AlF 3 and NaO 2 , choose PbO and ZnSe as the precursor of PbSe quantum dots, the mass fraction ratio is: SiO 2 :B 2 o 3 :Al 2 o 3 :ZnO:AlF 3 : NaO 2 :PbO:ZnSe=56.50%:4.33%:3.85%:8.57%:2.12%:15.11%:5.78%:3.74%. Weigh raw material SiO 2 : 56.50g; B 2 o 3 : 4.33g; Al 2 o 3 : 3.85g; ZnO: 8.57g; AlF 3 : 2.12g; NaO 2 ZnSe: 15.11g; PbO: 5.78g; ZnSe: 3.74g, put the above chemical raw materials in a ball mill and stir evenly, take them out and put them in a closed corundum crucible, then put them in a box-type electric furnace, melt at 1400 °C for 1 hour, and then The melt was poured onto a metal mold, cooled rapidly to room temperature, and yellow glass was obtained.

[0031] Then put the glass into a box-type electric furnace, heat-treat at 550°C for 5h, take it out and cool it to room temperature in the air, and obtain a pure black PbSe quantum dot silicate glass sample (denoted as G 2 ). Acco...

Embodiment 3

[0033] Glass matrix formula chooses SiO 2 , B 2 o 3 、Al 2 o 3 , ZnO, AlF 3 and NaO 2 , choose PbO and ZnSe as the precursor of PbSe quantum dots, the mass fraction ratio is: SiO 2 :B 2 o 3 :Al 2 o 3 :ZnO:AlF 3 : NaO 2 :PbO:ZnSe=56.50%:4.33%:3.85%:8.57%:2.12%:15.11%:5.78%:3.74%. Weigh raw material SiO 2 : 56.50g; B 2 o 3 : 4.33g; Al 2 o 3 : 3.85g; ZnO: 8.57g; AlF 3 : 2.12g; NaO 2 ZnSe: 15.11g; PbO: 5.78g; ZnSe: 3.74g, put the above chemical raw materials in a ball mill and stir evenly, take them out and put them in a closed corundum crucible, then put them in a box-type electric furnace, melt at 1400 °C for 1 hour, and then The melt was poured onto a metal mold, cooled rapidly to room temperature, and yellow glass was obtained.

[0034] Then put the glass into a box-type electric furnace, heat-treat at 600°C for 5h, take it out and cool it to room temperature in the air, and obtain a pure black PbSe quantum dot silicate glass sample (denoted as G 3 ). Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com