A method for preparing cesium garnet glass-ceramics by low-temperature liquid-phase sintering

A glass-ceramic, low-temperature liquid phase technology, applied in glass forming, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of high synthesis temperature, corrosion equipment, high temperature volatilization of Cs, etc. The effect of high temperature volatilization and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

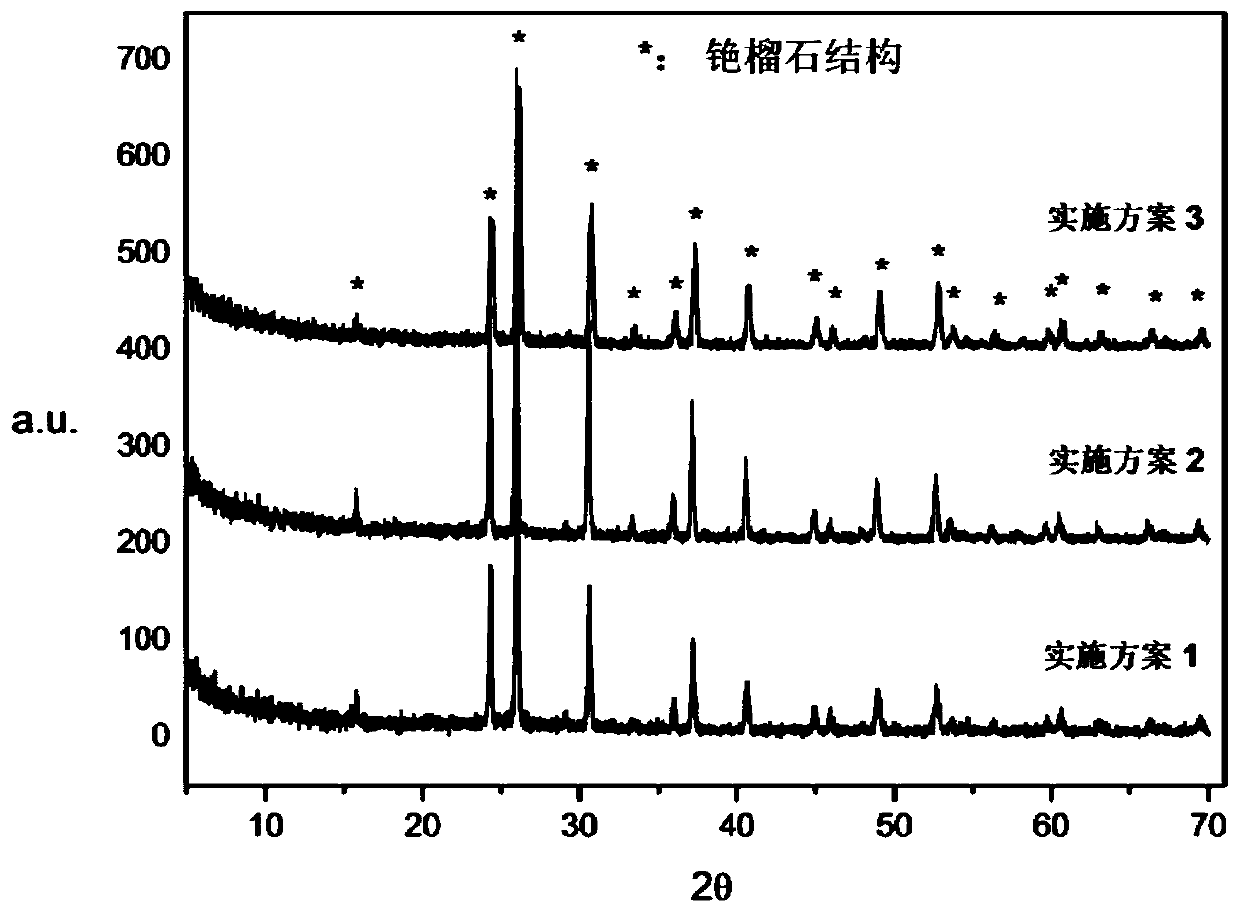

Embodiment 1

[0037] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0038] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 0.8 Na 1.2 O·Al 2 o 3 ·5SiO2 2 0.7B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0039] (2) add deionized water and carry out ball milling, ball milling time 8 hours;

[0040](3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0041] (4) After drying, the powder is ground, shaped and sintered. The sintering temperature is set at 650° C. and the sintering time is 3 hours to obtain a sample, which is designated as embodiment 1.

Embodiment 2

[0043] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0044] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 0.4 Na 1.6 O·Al 2 o 3 4SiO2 2 0.9B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0045] (2) Add deionized water and carry out ball milling, and the ball milling time is 9 hours;

[0046] (3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0047] (4) After drying, the powder is ground, shaped and sintered. The sintering temperature is set at 750° C. and the sintering time is 4 hours to obtain a sample, which is designated as embodiment 2.

Embodiment 3

[0049] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0050] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 1.8 Na 0.2 O·Al 2 o 3 ·6SiO2 2 1.2B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0051] (2) Add deionized water and carry out ball milling, and the ball milling time is 9 hours;

[0052] (3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0053] (4) After drying, the powder is ground, shaped and sintered, the sintering temperature is set at 950° C., and the sintering time is 4 hours to obtain a sample, which is designated as Embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com