Method for extracting scandium oxide from tungsten steel slag

A scandium oxide and steel slag technology is applied in the field of separation and recovery of scandium from tungsten steel slag, which can solve the problems of difficulty in extracting scandium oxide and low acidity of scandium-containing feed liquid, and achieves the effects of solving emulsification problems, separating fast and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

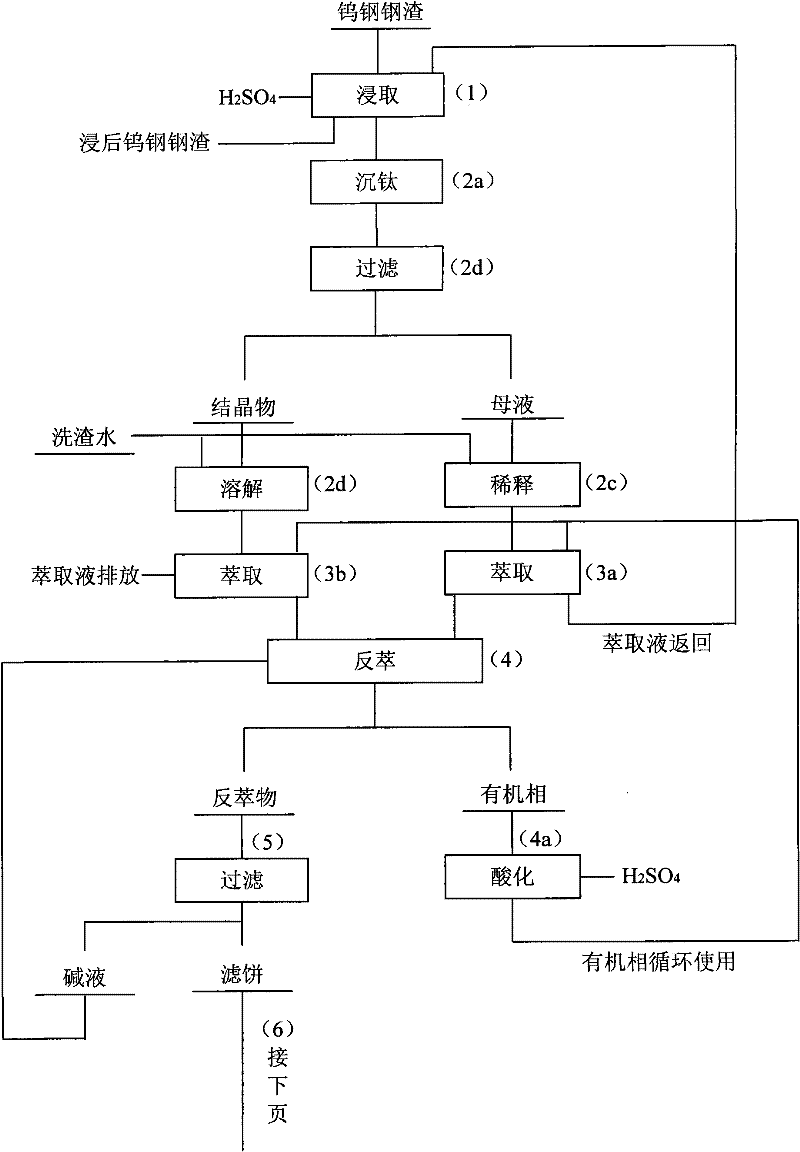

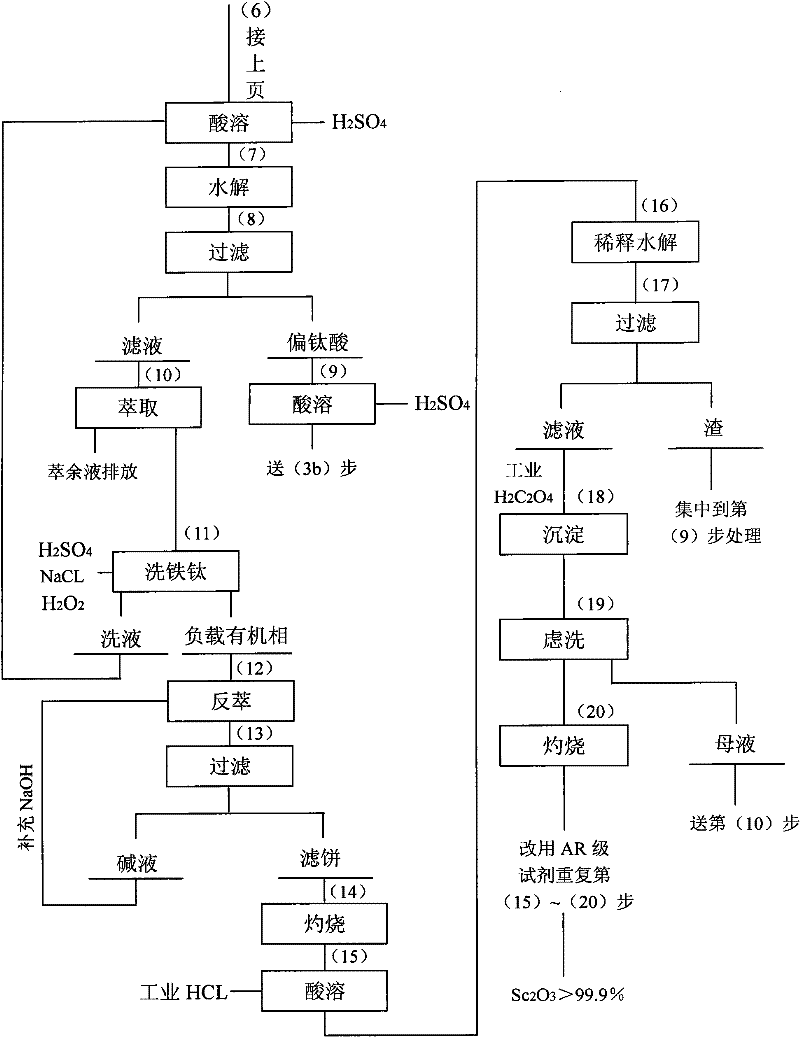

[0012] The operation steps of the present invention will be further described below with examples.

[0013] according to figure 1 The sequence shown illustrates the operational steps for carrying out this embodiment.

[0014] Leach 1.8 tons of tungsten steel slag with 1800 liters of 60% H2SO4 solution, that is, 1542 liters of material liquid ① for extraction obtained through steps ① and ②, which contains Sc2O356 mg / L, TiO255.83 g / L, Fe 21.25 g / L, H+12.8N; Feed liquid ②1009L, containing Sc2O384mg / L, TiO238.61g / L, Fe 31.50g / L, H+9.45N.

[0015] Feed liquid 1. use 20% di-(2-ethylhexyl) phosphoric acid (P204)+4% tributyl phosphate (TBP)+kerosene solvent in (3a), according to the volume of organic phase / water phase is 1:9 Compared with single-stage extraction, the raffinate contains Sc2O35.6 mg / L, TiO252.8 g / L, Fe 19.63 g / L, H + 12.4N, return to step ① to prepare acid. Feed liquid 2. through (3b) step adopts same extraction agent after single-stage extraction by the volume rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com