Super-capacitor pole piece with low internal resistance and manufacturing method thereof

A technology for supercapacitors and manufacturing methods, applied in the manufacture of hybrid/electric double layer capacitors, capacitors, electrolytic capacitors, etc., can solve the problems of low energy density of supercapacitors, achieve good application prospects, shorten mixing time, and reduce internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

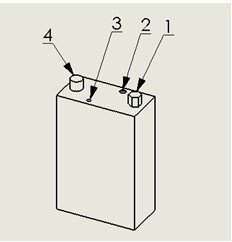

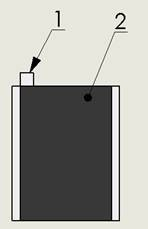

Image

Examples

Embodiment example 1

[0027] A metal aluminum mesh with a width of 300mm and a thickness of 0.1mm is used as the current collector of the electrode active material, wherein the width of the mesh area is 260mm, and a 20mm non-porous area is reserved on each side. The metal aluminum mesh is treated as follows: add a strong basic anionic surfactant, use ultrasonic technology to decontaminate the surface of the current collector for 1.5 minutes, wash it with secondary deionized water, and then vacuum dry it at 80°C for 10 minutes , and then use a fluorine-containing surfactant to modify the surface of the current collector for 4 minutes.

[0028] When preparing the electrode active material slurry, first weigh 20g of polyvinylidene fluoride PVDF and dissolve it in 200g of N-methylpyrrolidone (NMP), stir it to fully dissolve, then perform ultrasonic treatment for 3min, and then weigh 20g of Super- P Conductive carbon black, weigh 200g of activated carbon as electrode active material and fully perfo...

Embodiment example 2

[0031] Replace the conductive carbon black super-P in the implementation case 1 with conductive graphite KS-6. The conditions of slurry mixing, pole piece fabrication, battery assembly and testing are the same as those in comparative case 1. 10A charge and discharge, the internal resistance of the supercapacitor is 1.3mΩ, and the electrostatic capacity is 2100F.

[0032]

Embodiment example 3

[0034] The conductive carbon black super-P in Example 1 was replaced by a mixture of conductive graphite KS-6 and conductive carbon black, and the mass sum of the two remained unchanged. The conditions of slurry mixing, pole piece fabrication, battery assembly and testing are the same as those in comparative case 1. 10A charge and discharge, the internal resistance of the supercapacitor is 1.0mΩ, and the electrostatic capacity is 2200F.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com