BiFe1-yMnyO3 epitaxial composite film and preparation method thereof

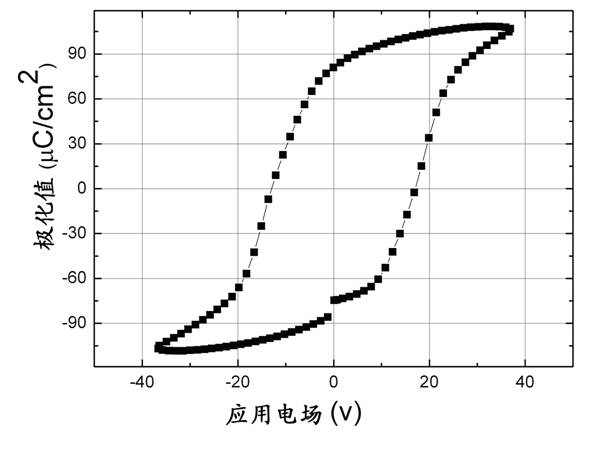

A composite thin film and thin film technology, which is applied in the field of microelectronics, can solve problems such as the widening of the coercive electric field distribution and the inability to completely solve the aging problem of the film, and achieve the effect of high remanent polarization and good practical prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

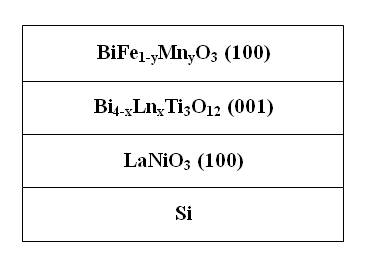

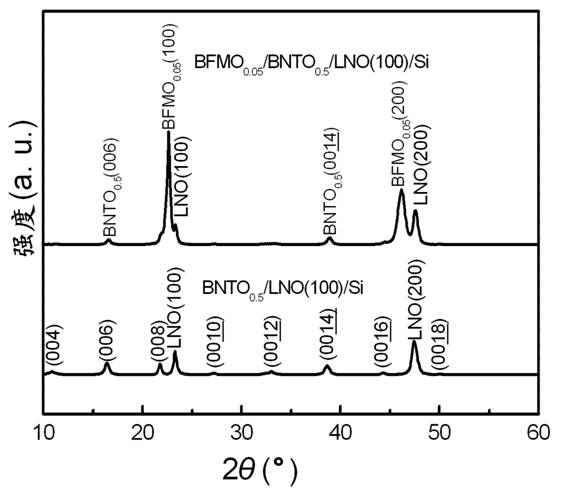

[0032] BiFe 1-y mn y o 3 The main layer of the epitaxial composite film is BiFe 0.95 mn 0.05 o 3 (BFMO 0.05 ) film, the transition layer is Bi 3.5 Nd 0.5 Ti 3 o 12 (BNTO 0.5 ), the electrode layer is LaNiO 3 Thin film, thin film preparation steps are as follows:

[0033] 1. LaNiO 3 Preparation of thin film: adopt chemical solution method, weigh lanthanum nitrate and nickel nitrate according to stoichiometric ratio and dissolve in ethylene glycol, prepare precursor solution according to conventional method, and prepare a solution with a concentration of 0.2mol / L, adopt layer by layer In the rapid annealing process, the precursor solution is first deposited on the Si substrate by the spin coating method, and then the material is placed on a hot plate for drying, and the dried film is pretreated in a rapid annealing furnace, and the pretreatment temperature is 450 ℃, the time is 5 minutes; the heat treatment temperature is 750 ℃, and the annealing time of each layer ...

Embodiment 2

[0038] BiFe deposited on Si substrate in the present invention 1-y mn y o 3 Epitaxial composite film whose main layer is BFMO 0.05 Thin film, transition layer is BNTO 0.5 , the electrode layer is LaNiO 3 film.

[0039] except BNTO 0.5 The final thickness of the film is 50nm, other preparation method Example 1.

Embodiment 3

[0041] BiFe deposited on Si substrate in the present invention 1-y mn y o3 Epitaxial composite film whose main layer is BFMO 0.05 Thin film, the transition layer is Bi 3.25 La 0.75 Ti 3 o 12 , the electrode layer is LaNiO 3 film.

[0042] The film preparation method is as follows:

[0043] 1. LaNiO 3 Preparation of film: same as Example 1.

[0044] 2. Bi 3.25 La 0.75 Ti 3 o 12 Preparation of the thin film: adopt the chemical solution method, respectively weigh bismuth nitrate and lanthanum nitrate with a molar ratio of 3.575: 0.5, dissolve them in 30 ml of ethylene glycol, and use the molar ratio of bismuth: lanthanum: titanium as 3.575: 0.5:3 Measure tetrabutyl titanate by converting it into the corresponding volume, complex tetrabutyl titanate and acetylacetone according to the volume ratio of 1:1 and stir them evenly, then mix them together to prepare 0.10 mol / L Precursor solution, the precursor solution was deposited on LNO(100) / Si by spin coating method, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com