a bi 6 ti 3 fe 2 o 18 Layered multiferroic epitaxial thin film and its preparation method

A bi6ti3fe2o18, epitaxial thin film technology, applied in the field of new material preparation, can solve the problems of complex chemical composition of multiferroic thin films, easy generation of impurity phases and complex chemical composition in the preparation process, and achieve excellent room temperature ferroelectric properties, good epitaxial properties, crystallization high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

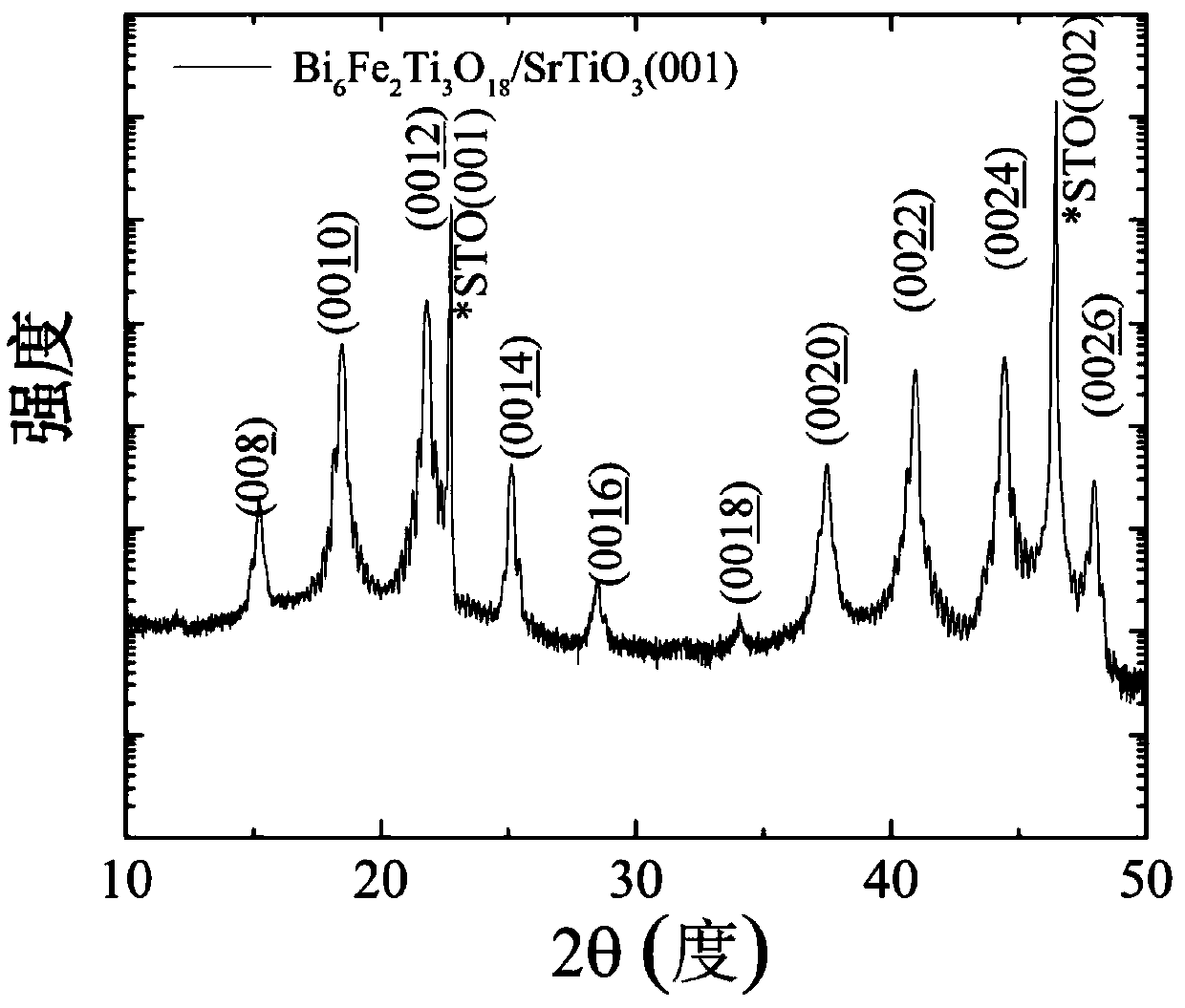

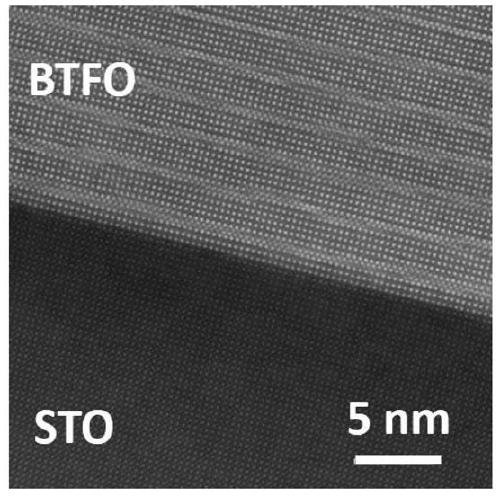

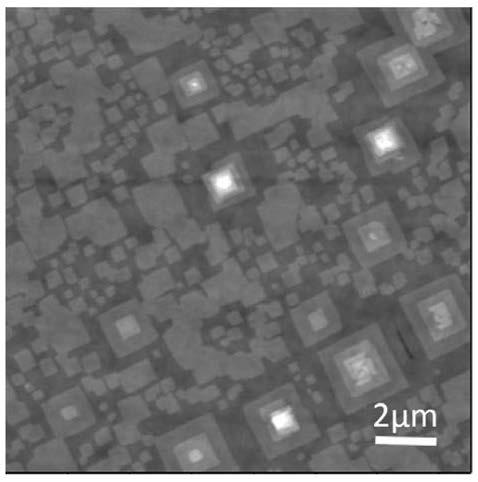

[0033] The present invention relates to a Bi 6 Ti 3 Fe 2 o 18 Multiferroic epitaxial thin film and its preparation method. The method is to combine the two-layer octahedral group BiFeO 3 Insertion into a three-layer layered perovskite ferroelectric Bi 4 Ti 3 o 12 Formation of a novel eight-layer layered perovskite Bi 6 Ti 3 Fe 2 o 18 Multiferroic epitaxial thin films. The present invention utilizes the pulsed laser deposition method to coat a film on a single crystal substrate, and after the deposition is completed, the 2 In-situ annealing treatment in the atmosphere, for the first time obtained Bi with room temperature ferroelectric and ferromagnetic properties and excellent quality 6 Ti 3 Fe 2 o 18 Layered multiferroic epitaxial thin films. The method requires simple equipment and is compatible with microelectronic technology. Prepared Bi 6 Ti 3 Fe 2 o 18 The layered multiferroic thin film has high phase purity and is an excellent room temperature multif...

Embodiment 1

[0059] (a) Bi 6 Ti 3 Fe 2 o 18 Target compression: to analyze pure bismuth oxide (Bi 2 o 3 ), titanium dioxide (TiO 2 ), iron oxide (Fe 2 o 3 ) as the main raw material, and the raw material ratio is Bi:Ti:Fe=6.48:3:2; mix the powder raw materials, put them into an automatic mortar to fully mix and grind for more than 24 hours; put the mixed powder into the mold for pre- Press molding, the shape is cylindrical, the diameter is 2cm, and the thickness is 0.5cm; it is pressed into Bi by cold isostatic pressing. 6 Ti 3 Fe 2 o 18 Target material, load pressure 260MPa, pressure holding time 8min.

[0060] (b) Preparation and cleaning of the substrate: using (001) oriented strontium titanate (SrTiO 3 ) single crystal substrate as the growth substrate, and ultrasonically cleaned with organic solvents such as acetone and isopropanol in sequence for 5 minutes, and finally dried with a nitrogen gun.

[0061] (c) Bi 6 Ti 3 Fe 2 o 18 Thin film growth: use the pulsed laser ...

Embodiment 2

[0065] (a) Bi 6 Ti 3 Fe 2 o 18 Target compression: to analyze pure bismuth oxide (Bi 2 o 3 ), titanium dioxide (TiO 2 ), iron oxide (Fe 2 o 3 ) as the main raw material, the raw material ratio is Bi:Ti:Fe=6.5:3:2; put it into an automatic mortar for full mixing and grinding for more than 24 hours; put the mixed powder into a mold for pre-compression molding, and the shape is a cylinder Shape, 2cm in diameter, 0.5cm in thickness; pressed into Bi by cold isostatic pressing 6 Ti 3 Fe 2 o 18 Target material, load pressure 180MPa, pressure holding time 20min.

[0066] (b) Preparation and cleaning of the substrate: using (110)-oriented dysprosium scandate (DyScO 3 ) single crystal substrate as the growth substrate, and ultrasonically cleaned with organic solvents such as acetone and isopropanol in sequence for 5 minutes, and finally dried with a nitrogen gun.

[0067] (c) Bi 6 Ti 3 Fe 2 o 18 Thin film growth: use the pulsed laser deposition method, fix the target in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com