High-performance porous film silicon-based negative electrode material of lithium ion cell and preparation method thereof

A technology for silicon-based negative electrode materials and lithium-ion batteries, applied in battery electrodes, electrode carriers/collectors, circuits, etc., can solve problems such as low electrical conductivity and affect the cycle performance of electrode materials, so as to improve synergy and improve charge and discharge Cycle performance, effect of reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

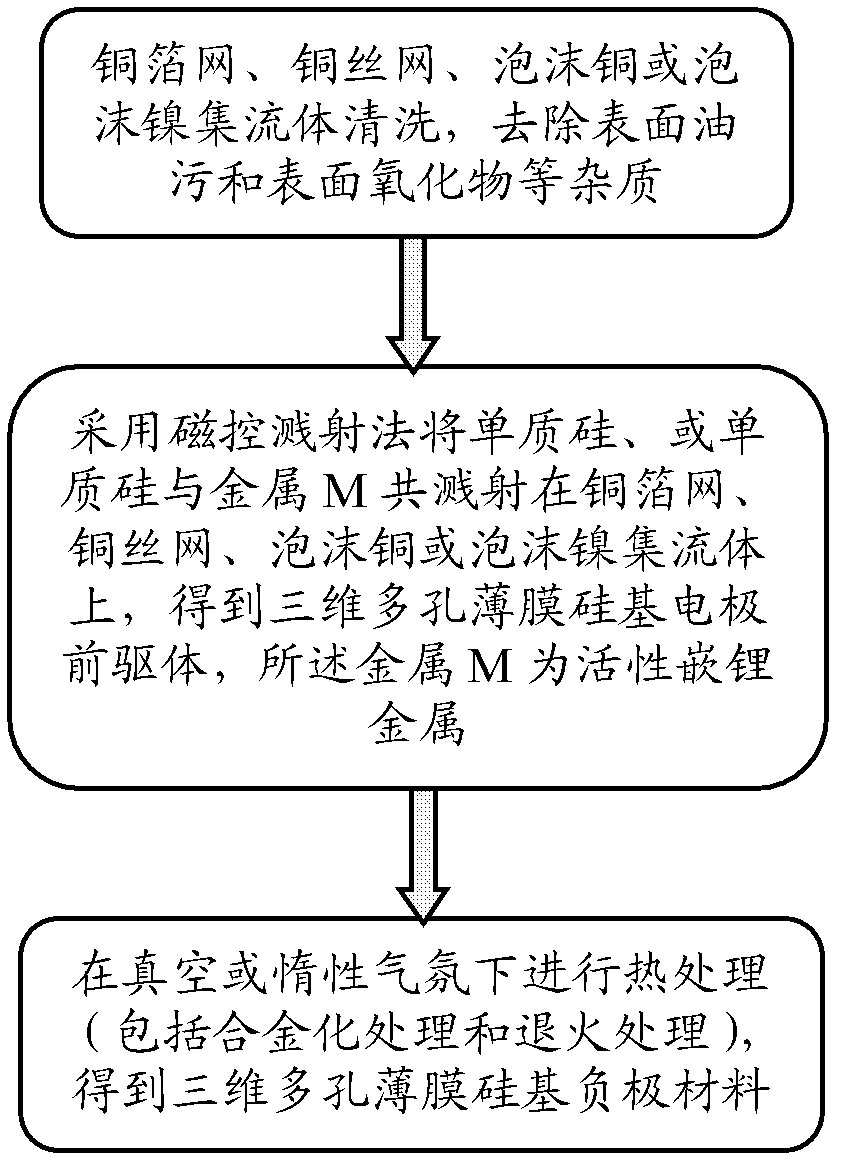

Method used

Image

Examples

Embodiment 1

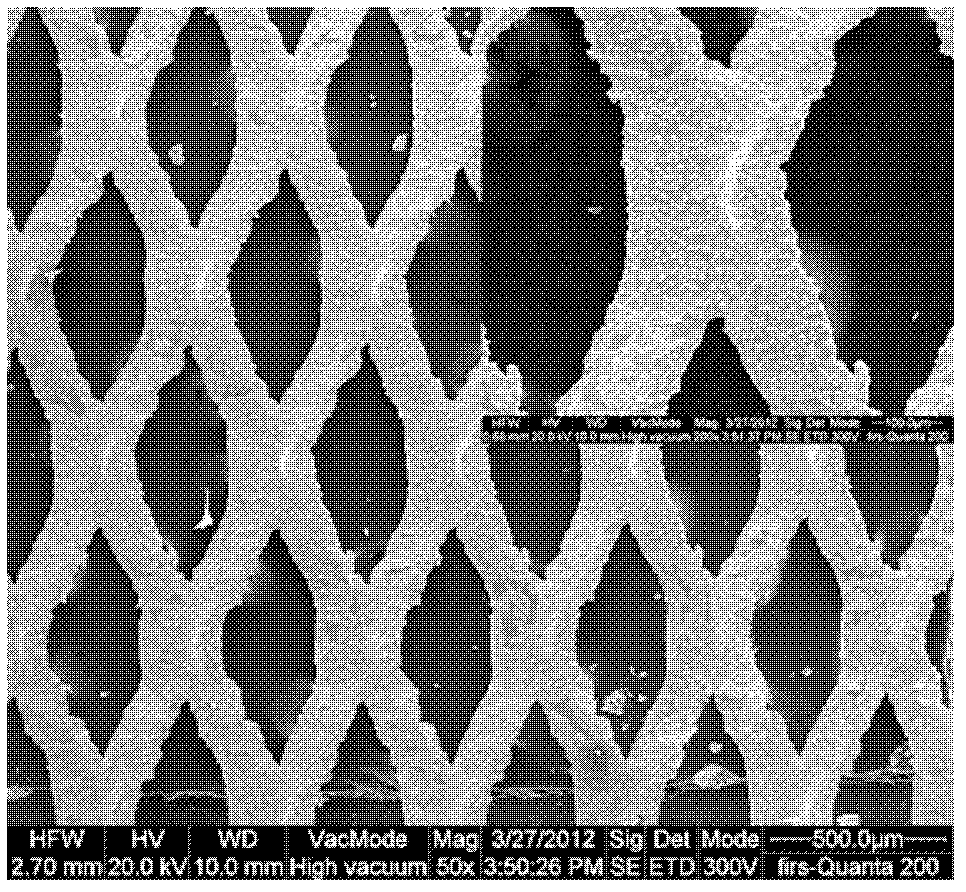

[0037] The copper foil net with a porosity of 98.0%, an average pore diameter of 100μm and a thickness of 70μm is ultrasonically cleaned with acrylic copper, 10% (mass percentage) dilute hydrochloric acid, distilled water and absolute ethanol to remove surface oil and surface oxides and other impurities . Magnetron sputtering method is adopted, Si with a purity of 99.99% is used as the target, the copper foil net current collector is used as the substrate, and the background vacuum is 1.0×10 -3 Pa, the working pressure during sputtering is 0.2Pa, the flow of argon Ar is 40sccm, the sputtering power of the Si target is 150W, the sample stage revolution speed is 15rpm, the sputtering time is 2 hours, and the thickness of the film obtained by sputtering is 300nm. The obtained three-dimensional porous film silicon-based electrode precursor is placed in a box furnace and heat-treated in a vacuum or inert atmosphere. The heat treatment temperature is 700°C, the heating rate is 12°C / mi...

Embodiment 2

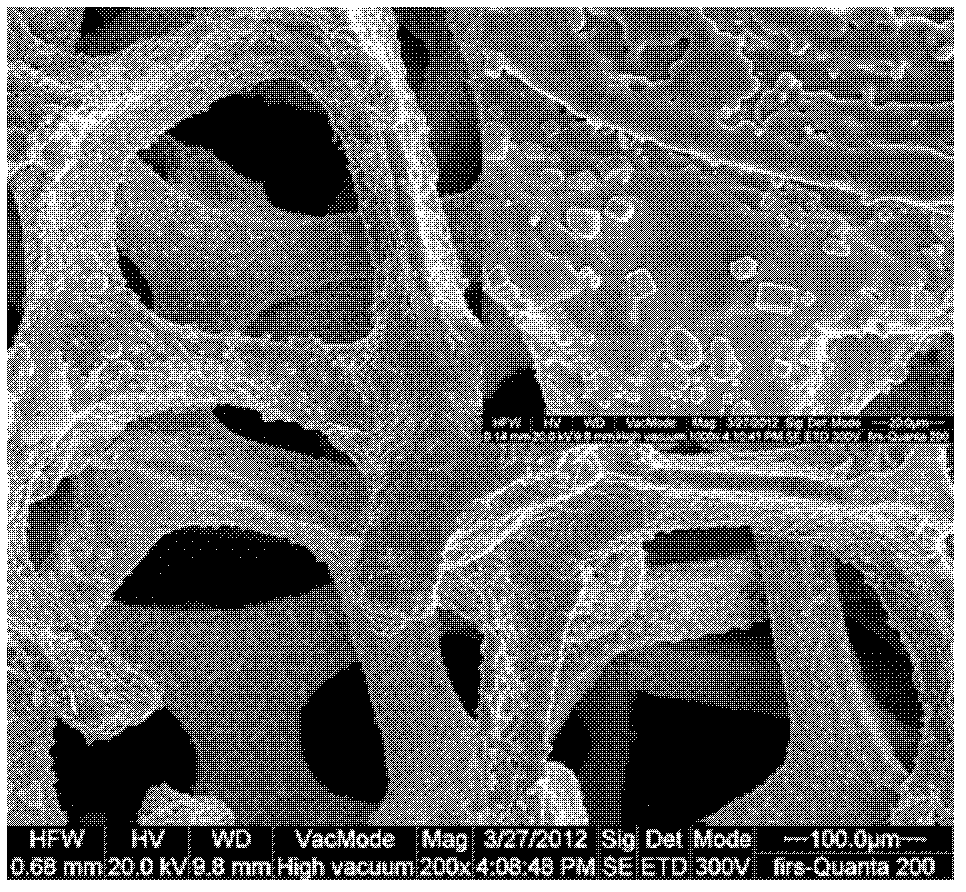

[0040] The foamed copper with a porosity of 98.0%, an average pore diameter of 150 μm and a thickness of 400 μm is ultrasonically cleaned with acrylic copper, 10% (mass percentage) dilute hydrochloric acid, distilled water and absolute ethanol to remove surface oil and surface oxides. Magnetron sputtering method is adopted, Si with a purity of 99.999% is used as the target, and the foamed copper current collector is used as the matrix. The background vacuum is 1.0×10 -4 Pa, working pressure during sputtering is 0.8Pa, flow of argon Ar is 60sccm, Si target sputtering power is 300W, sample stage revolution speed is 20rpm, sputtering time is 8 hours, and the film thickness obtained by sputtering is 1.0μm. The obtained three-dimensional porous film silicon-based electrode precursor is placed in a box furnace and heat-treated in a vacuum or inert atmosphere. The heat treatment temperature is 800°C, the heating rate is 15°C / min, and the holding time is 2 hours. Alloying treatment; the...

Embodiment 3

[0043] The copper foil net with a porosity of 98.0%, an average pore diameter of 50μm and a thickness of 50μm is ultrasonically cleaned with acrylic copper, 10% (mass percentage) dilute hydrochloric acid, distilled water and absolute ethanol to remove surface oil and surface oxides. . The magnetron sputtering method is adopted, with Si with a purity of 99.998% and Sn with a purity of 99.99% as the target material (and Si:Sn=1:1), the copper foil net current collector is the substrate, and the background vacuum degree is 2.0× 10 -4 Pa, the working pressure during sputtering is 0.3Pa, the flow of argon Ar is 40sccm, the sputtering power of Si target is 200W, the sputtering power of Sn target is 25W, the sample stage revolution speed is 18rpm, the sputtering time is 8 hours, and the sputtering The thickness of the film obtained by the injection was 3.0 μm. The obtained three-dimensional porous film silicon-based electrode precursor is placed in a box furnace and heat-treated in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com