Eutectic soldering equipment of LED wafer

A eutectic welding and wafer technology, applied in the field of LED chip eutectic welding equipment, can solve the problems of slow heating speed, low maximum temperature, affecting heating effect, etc., achieve good thermal conductivity, improve eutectic accuracy, and speed up heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

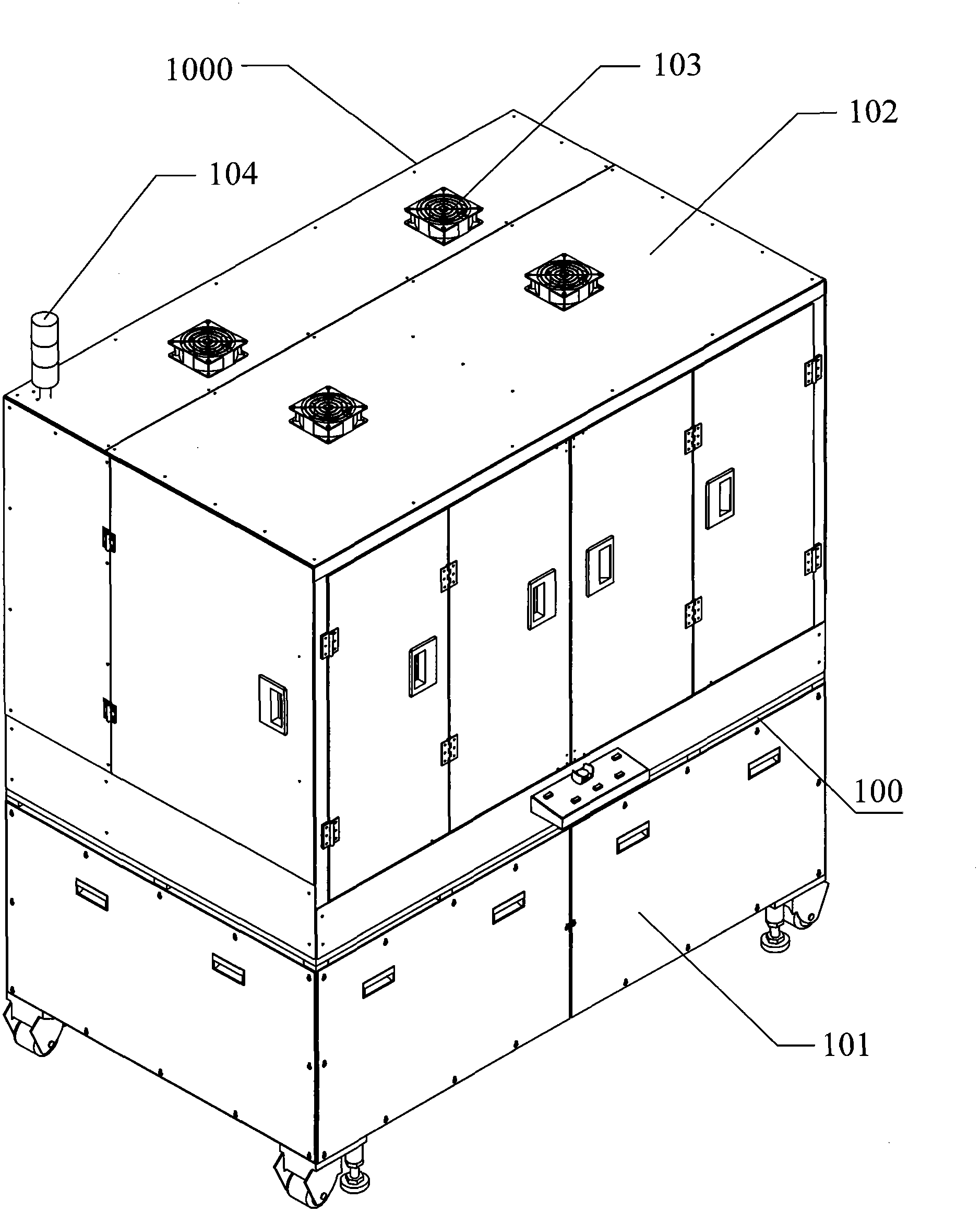

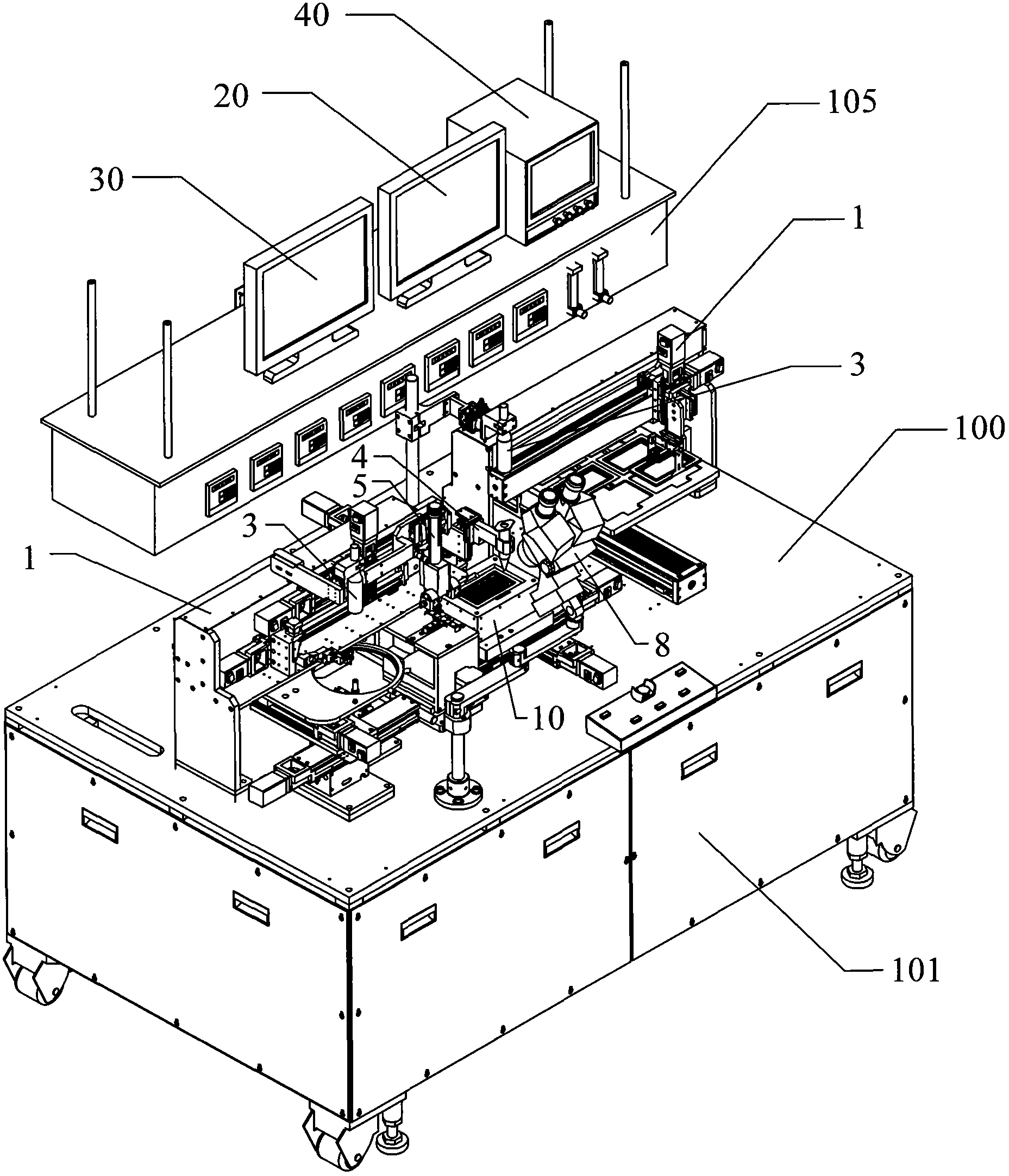

[0055] Reference below Figure 1-Figure 7 Describe in detail an embodiment of the LED chip eutectic welding equipment of the present invention; figure 1 As shown, this embodiment mainly includes a fuselage 1000. The fuselage 1000 mainly includes a bottom box 101 and an upper box 102. The bottom box 102 is provided with a power configuration box (not shown in the figure) and a bottom box. A welding workbench 100 is provided on 102, and a cooling fan 103 and a warning light 104 are provided on the top plate of the upper box 102.

[0056] Also, please refer to figure 2 , The upper box 102 is provided with:

[0057] Drive control system (not shown in the figure), mainly including servo drive system and single-chip control system;

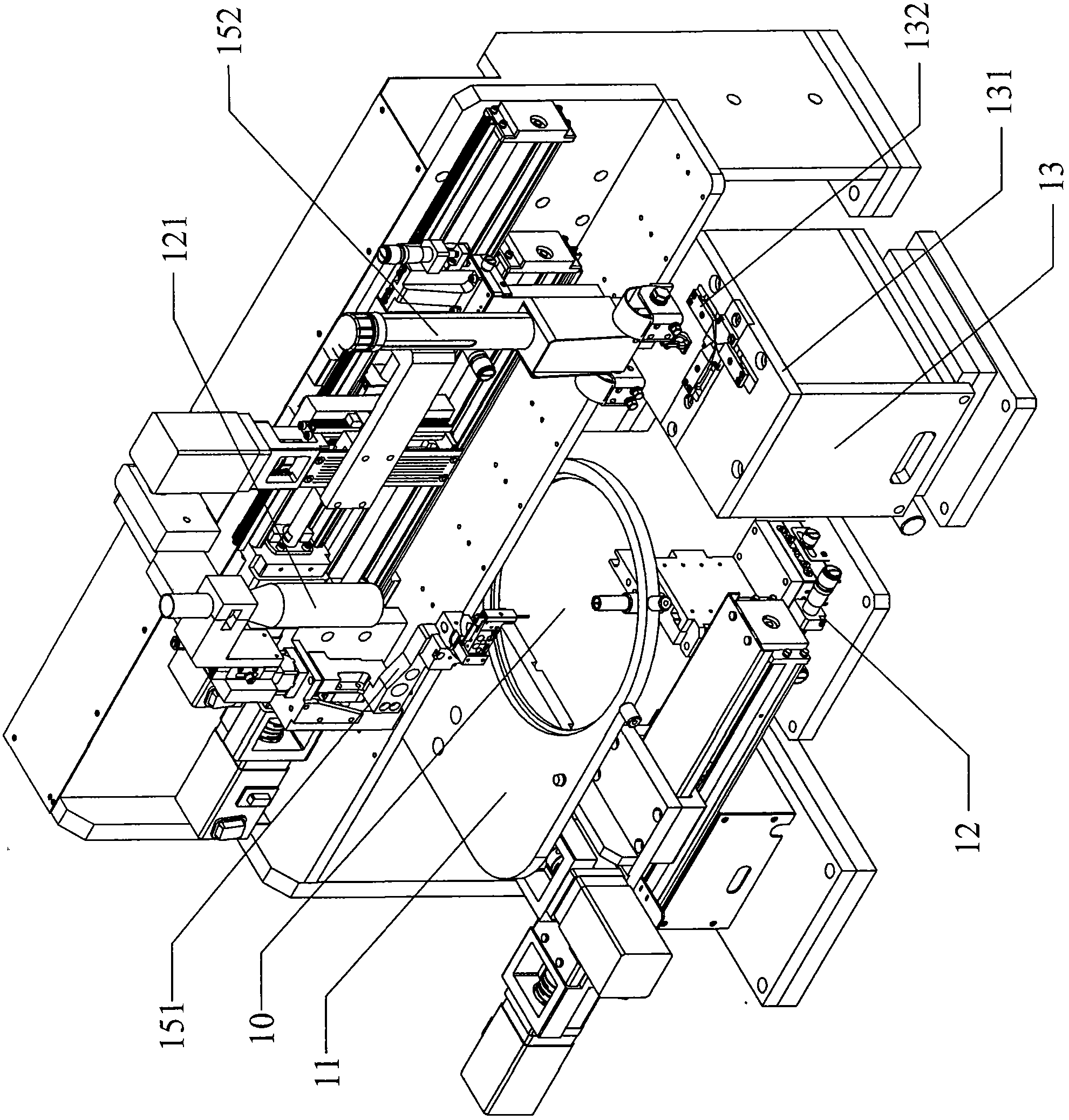

[0058] The eutectic welding platform 10 set in the middle of the front of the welding workbench 100 for placing the chip to be welded and the bracket;

[0059] They are respectively arranged around the sides and the rear of the eutectic welding platform 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com