Nickeliferous fluorescent quantum dot and preparation method and application thereof

A fluorescent quantum dot, quantum dot technology, applied in photosensitive equipment, chemical instruments and methods, luminescent materials, etc., can solve the problems of limited variety of quantum dots, the stay of nickel-containing semiconductor materials, and the limitation of quantum dot theory expansion and improvement. The effect of good fluorescence stability and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of Reaction Precursor

[0034] Weigh 0.238g NiCl 2 After dissolving in 30g of deionized water, add a toluene solution in which 1g of oleic acid is dissolved in the system, fully stir to form a water-oil reaction system, and then heat to 70°C for 1 hour under nitrogen gas to obtain a reaction precursor solution.

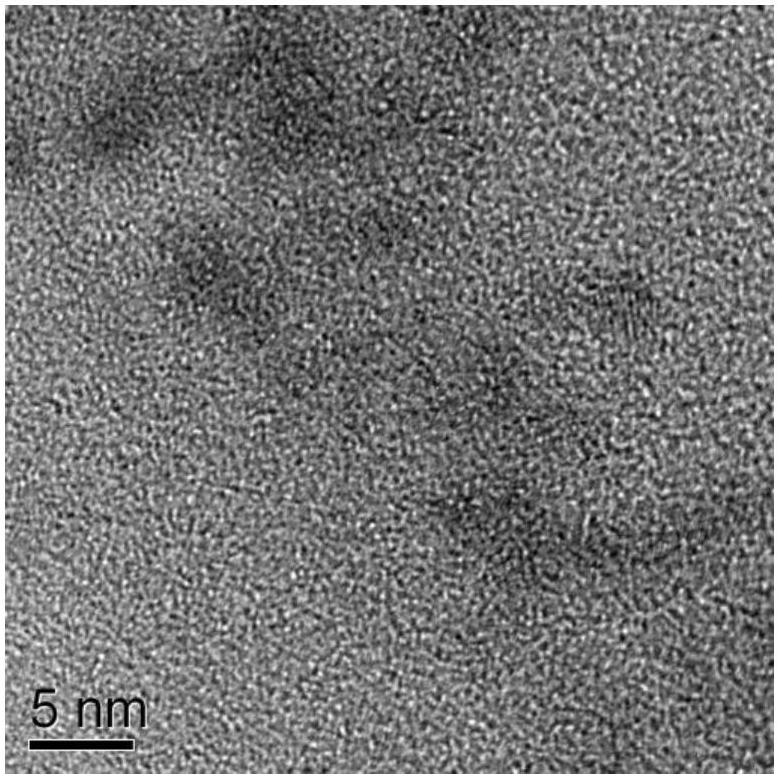

[0035] 2. Preparation of NiSe quantum dots

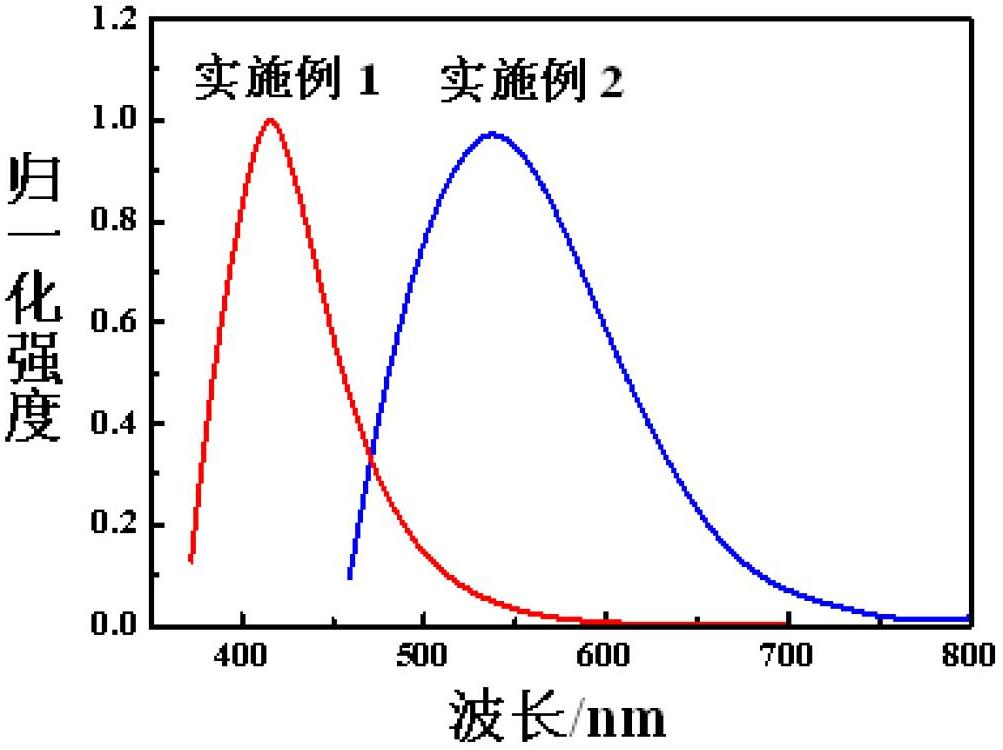

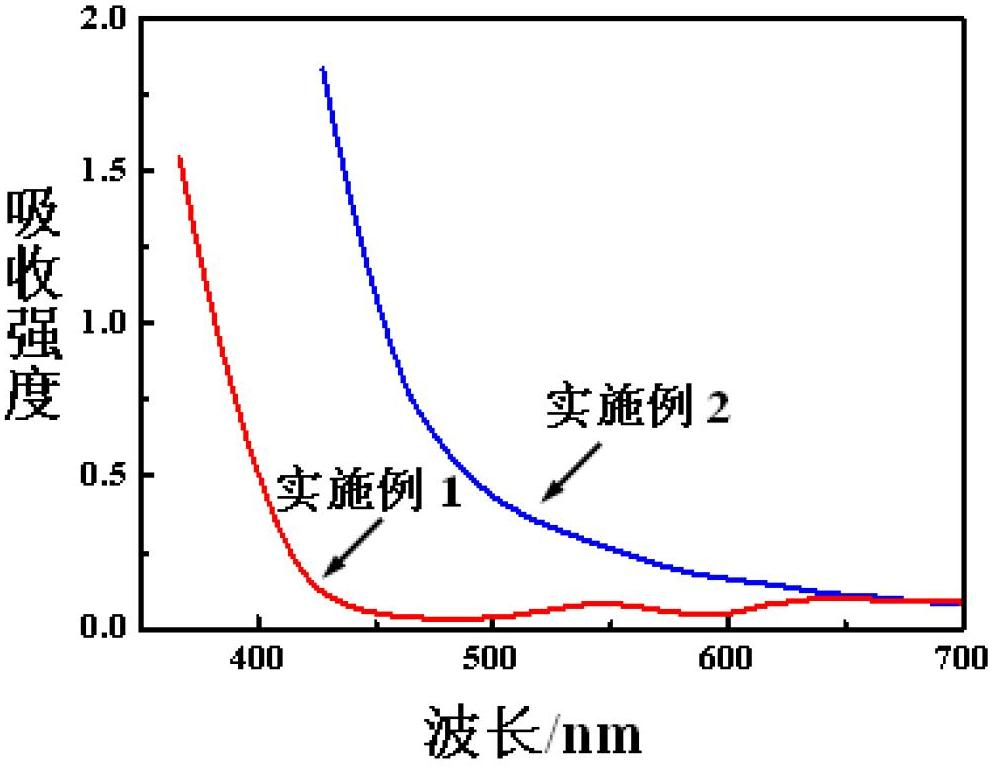

[0036] Weigh 0.0227g NaBH 4 and 0.4g of Se powder, dissolved in 1g of pure water, and reacted in an ice-water bath for about 5 hours to obtain a purple-red NaHSe solution, which was then injected into the reaction precursor solution under a hot nitrogen atmosphere, and the reaction was stopped after 10 hours. Take the upper toluene phase solution and precipitate it with a large amount of ethanol, centrifuge at 8000 rpm for 15 minutes and then disperse it in toluene. After repeated repetitions, a blue fluorescent NiSe quantum dot solution is obtained.

[0037] 3. Construction of quantum dot-sensitize...

Embodiment 2

[0040] 1. Preparation of Reaction Precursor

[0041] Weigh 0.238g NiCl 2 After dissolving in 30g of deionized water, add toluene solution in which 0.8g of undecylenic acid is dissolved in the system, fully stir to form a water-oil reaction system, and then heat to 90°C for 1 hour under nitrogen gas to obtain a reaction precursor solution.

[0042] 2. Preparation of NiSe quantum dots

[0043] Weigh 0.0227g NaBH 4 and 0.4g of Se powder, dissolved in 1g of pure water, and reacted in an ice bath for about 5 hours to obtain a purple-red NaHSe solution, which was then injected into the reaction precursor solution under a hot nitrogen atmosphere, and the reaction was stopped after 20 hours. Take the upper toluene phase solution and precipitate it with a large amount of ethanol, centrifuge at 8000 rpm for 15 minutes and then disperse it in toluene. After repeated repetitions, a yellow fluorescent NiSe quantum dot solution is obtained.

[0044] 3. Fabrication of Light-Emitting Devic...

Embodiment 3

[0047] 1. Preparation of Reaction Precursor

[0048] Weigh 0.47g NiCl 2 After dissolving in 30g of deionized water, add a toluene solution in which 2g of oleic acid is dissolved in the system, fully stir to form a water-oil reaction system, and heat to 70°C after nitrogen gas for 1h to obtain a reaction precursor solution.

[0049] 2. Preparation of NiTe quantum dots

[0050] Weigh 0.0227g NaBH 4 and 0.3g of Te powder, dissolved in 1g of pure water and reacted in an ice bath for about 5 hours to obtain a deep purple NaHTe solution, which was then injected into the reaction precursor solution under a hot nitrogen atmosphere, and the reaction was stopped after 10 hours. Take the upper toluene phase solution and precipitate it with a large amount of ethanol, centrifuge at 8000 rpm for 15 minutes and then disperse it in toluene. After repeated repetitions, a blue fluorescent NiTe quantum dot solution is obtained.

[0051] 3. Construction of NiTe quantum dot-sensitized solar cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com