Preparation method and application of fungal hypha nitrogen and sulfur self-doped carbon dots

A self-doping and hyphae technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., to achieve low cytotoxicity, simple preparation technology, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

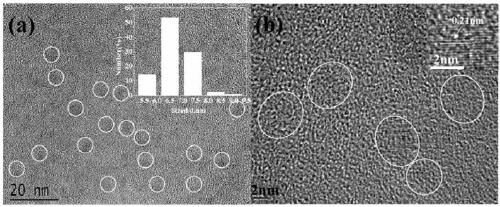

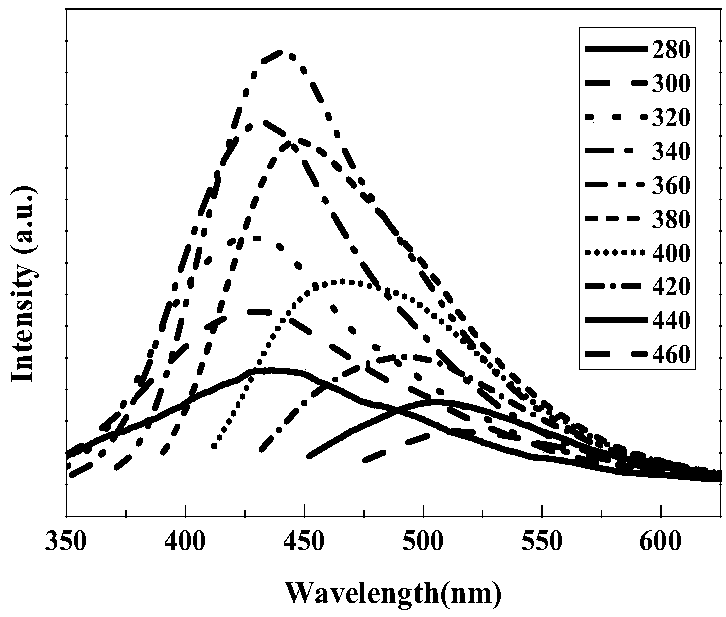

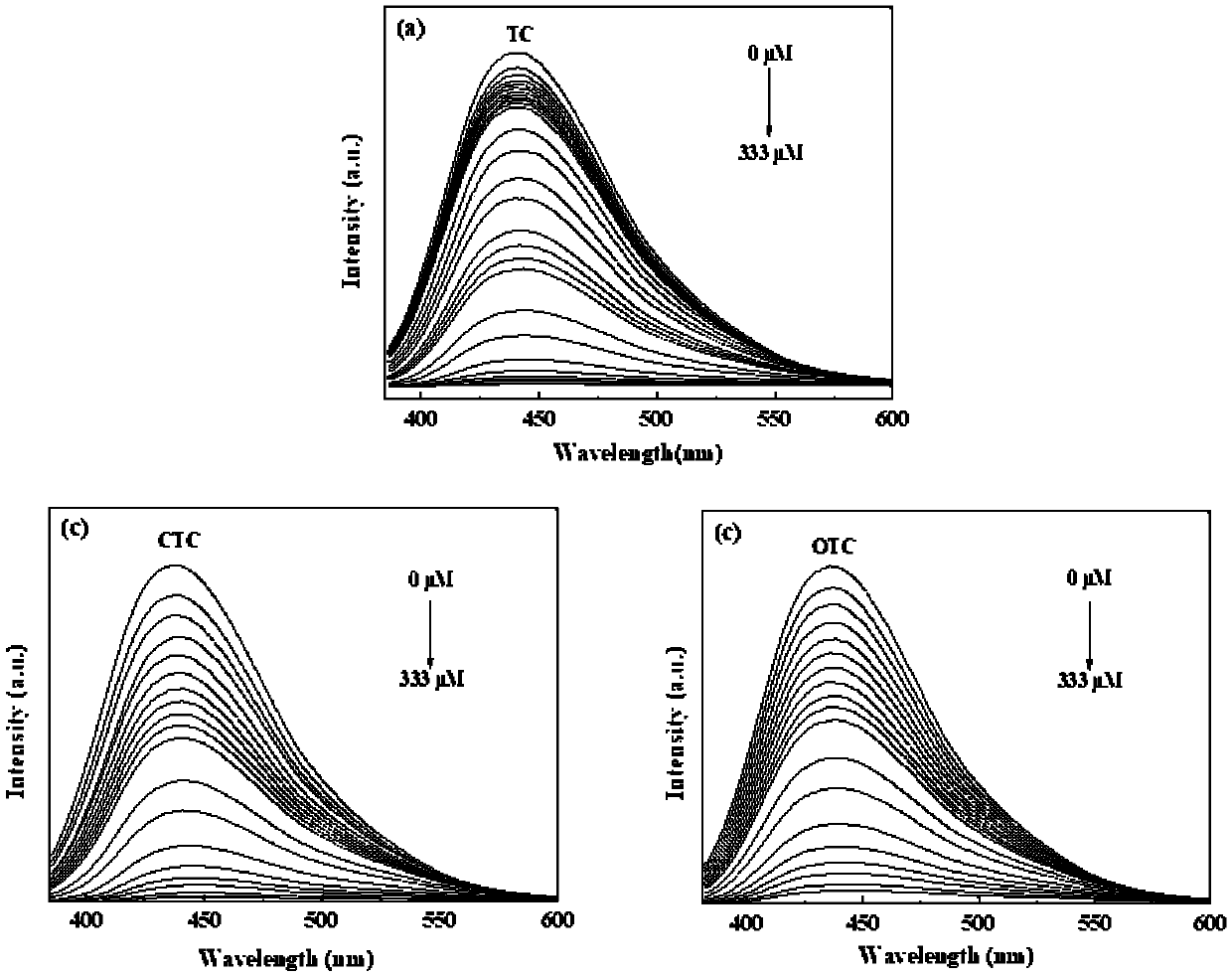

Embodiment 1

[0014] The preparation method and application of the nitrogen and sulfur self-doping carbon dots of fungal hyphae of the present invention are specifically carried out according to the following steps: the fungal mycelium is synthesized by biosynthesis technology. The fungal hyphae were cultured in the PDA solid medium at a constant temperature of 25°C. After the mycelium covered the surface, the above-mentioned mycelium was inoculated in the PDA liquid medium, and placed in a 160r / min constant temperature shaker for 25 Cultivate at ℃ for 10 days, and finally purify the fungal hyphae with dilute lye with a concentration of 0.5mol / L, boil for 30 minutes, wash with deionized water until neutral, freeze-dry for later use; (2) use the above-mentioned biosynthesized fungi Take silk as raw material, take 2g and add it into 25mL deionized water, stir magnetically for 30min to form a homogeneous mixture; (3) transfer the mixture to a 50mL hydrothermal reactor, and react in a homogeneou...

Embodiment 2

[0016] Using biosynthesis technology to synthesize fungal hyphae. The fungal hyphae are cultivated at a constant temperature under 25°C environmental conditions in the PDA solid medium, and the surface is covered with the mycelia, and then the above-mentioned mycelium is inoculated in the modified PDA liquid medium (the mass ratio of the amino acid to the PDA liquid medium is 1 :15), placed in a constant temperature oscillator at 120-160r / min, cultivated at 25-30°C for 6-14 days, and finally purified the fungal hyphae with dilute lye, washed with deionized water until neutral, and freeze-dried for later use ; With the above-mentioned biosynthetic fungal hyphae as raw material, 1 g was added to 25 mL of deionized water, and magnetically stirred for 30 min to form a uniform mixture; React at ℃ for 6 hours; after the reaction is completed, cool it down naturally to room temperature, then centrifuge the obtained dark brown liquid at 8000rpm for 15 minutes to remove large particles...

Embodiment 3

[0018] Using biosynthesis technology to synthesize fungal hyphae. The fungal hyphae are cultivated at a constant temperature under 25°C environmental conditions in the PDA solid medium, and the surface is covered with the mycelia, and then the above-mentioned mycelium is inoculated in the modified PDA liquid medium (the mass ratio of the amino acid to the PDA liquid medium is 1 :10), placed in a constant temperature oscillator at 120r / min, cultivated at 30°C for 5 days, and finally purified the mycelium of the fungus with dilute lye, washed with deionized water until neutral, and freeze-dried for later use; the above biosynthesized Fungal hyphae as raw material, take 1.5g and add it to 25mL deionized water, and stir it magnetically for 30min to form a uniform mixture; transfer the mixture to a microwave oven and react in the microwave oven at 100°C for 5min; After cooling down to room temperature, the obtained dark brown liquid was centrifuged at 8000 rpm for 15 min to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com