Production method and application of needle-point graphene electrochemical electrode

A kind of ene electrochemistry and electrochemistry technology, which is applied in the preparation and application field of needle-point graphene electrochemical electrodes, and achieves the effects of simple preparation process, easy functional modification and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

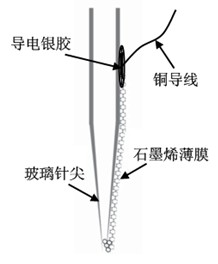

[0030] Direct transfer of graphene films synthesized by chemical vapor deposition onto glass tip surfaces;

[0031] Use 0.5 mg of conductive silver glue to connect one end of the graphene film to one end of the metal wire. After the silver glue is cured for 15 minutes, a non-functional needle-point graphene electrochemical electrode can be obtained;

[0032] The tip diameter of the glass needle tip is 5.0 µm.

[0033] The metal wire is made of copper.

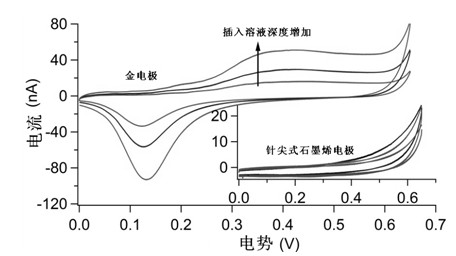

[0034] figure 1 Schematic diagram of the structure of the needle-tip graphene electrochemical electrode prepared by the above method; figure 2 Comparison of the cyclic voltammetry curves of the needle-tip graphene electrochemical electrode prepared by the above method and that of the gold nanoelectrode.

Embodiment 2

[0036] Direct transfer of graphene films synthesized by chemical vapor deposition onto glass tip surfaces;

[0037] Connect one end of the graphene film to one end of the metal wire with 0.5 mg of conductive silver glue, and obtain a non-functional needle-point graphene electrochemical electrode after the silver glue is cured for 15 minutes;

[0038] The tip diameter of the glass needle tip is 1.0 μm.

[0039] The metal wire material is titanium.

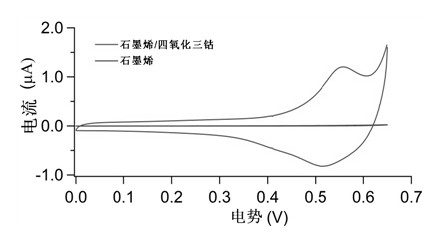

[0040] A 10.0 mmol cobalt nitrate aqueous solution was used as the electrolyte, and a layer of cobalt hydroxide was deposited on the surface of the needle-tip graphene by electrochemical deposition at a constant potential of -1.0 volts for 60 seconds.

[0041] After the graphene tip with cobalt hydroxide deposited on the surface is washed and dried, it is placed in a muffle furnace and baked at 400° C. for 2 hours to obtain a functionalized tip-type graphene electrochemical electrode modified by tricobalt tetroxide.

[0042] ima...

Embodiment 3

[0044] Direct transfer of graphene films synthesized by chemical vapor deposition onto glass tip surfaces;

[0045] Connect one end of the graphene film to one end of the metal wire with 0.5 mg of conductive silver glue, and obtain a non-functional needle-point graphene electrochemical electrode after the silver glue is cured for 15 minutes;

[0046] The tip diameter of the glass needle tip is 1.0 μm.

[0047] The metal wire is made of copper.

[0048] A 10.0 mmol cobalt nitrate aqueous solution was used as the electrolyte, and a layer of cobalt hydroxide was deposited on the surface of the needle-tip graphene by electrochemical deposition at a constant potential of -1.0 volts for 60 seconds.

[0049] After the graphene tip with cobalt hydroxide deposited on the surface is washed and dried, it is placed in a muffle furnace and baked at 400° C. for 2 hours to obtain a functionalized tip-type graphene electrochemical electrode modified by tricobalt tetroxide.

[0050] Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com