Oil-water separating mesh film and preparation method thereof

An oil-water separation mesh membrane and phase separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complex preparation process, difficult to degrade, difficult to handle, etc., and achieve the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the preparation of oil-water separation omentum

[0041] 1. Dissolve PLA (polylactic acid, Shenzhen Guanghua Weiye Industrial Co., Ltd., molecular weight = 69000, L-polylactic acid) in 1,4-dioxane solvent to prepare a PLA solution with a concentration of 0.1g / mL, and take 4ml PLA solution, then add sodium chloride crystals (0.15g, the mass ratio of PLA and sodium chloride is 8:3), stir to form a uniform mixture, then spread the mixture evenly on the glass substrate, and let it stand in the air for 3min (to make the PLA solution flat), then immerse the glass substrate covered with the mixed solution in absolute ethanol, and perform phase separation for 30 minutes to form a film;

[0042] 2. Take out the above-mentioned glass substrate with film and immerse it in water again to remove the porogen sodium chloride, take it out after 10 hours and put it in an oven to dry at 40°C to obtain an oil-water separation omentum.

Embodiment 2

[0043] Embodiment 2, the characteristic and functional identification of oil-water separation omentum

[0044] 1. Electron microscope scanning observation aperture

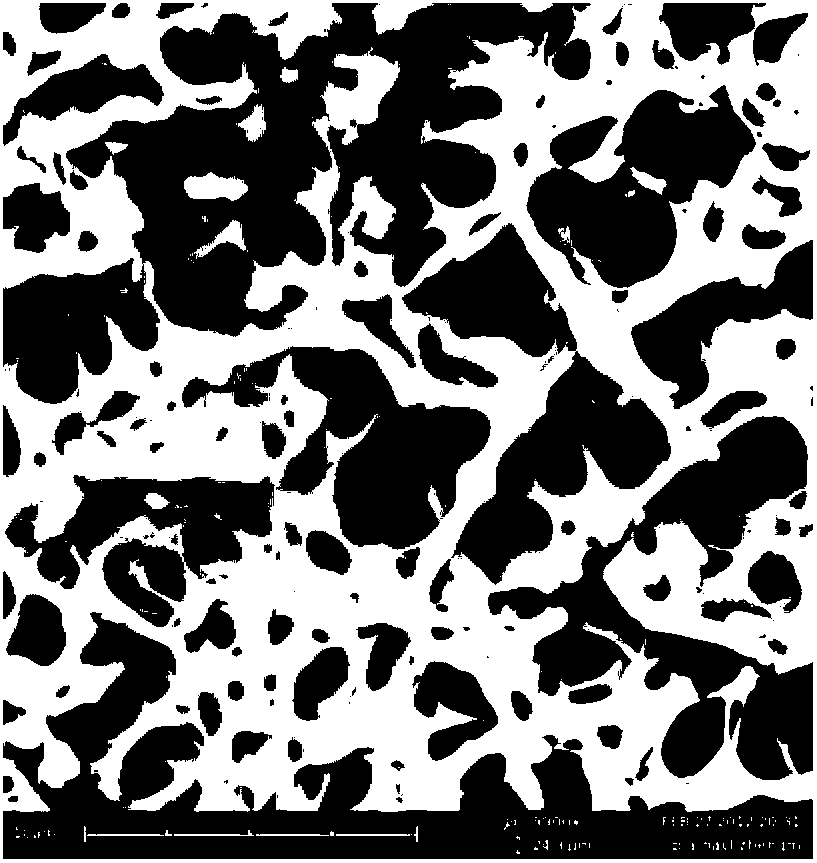

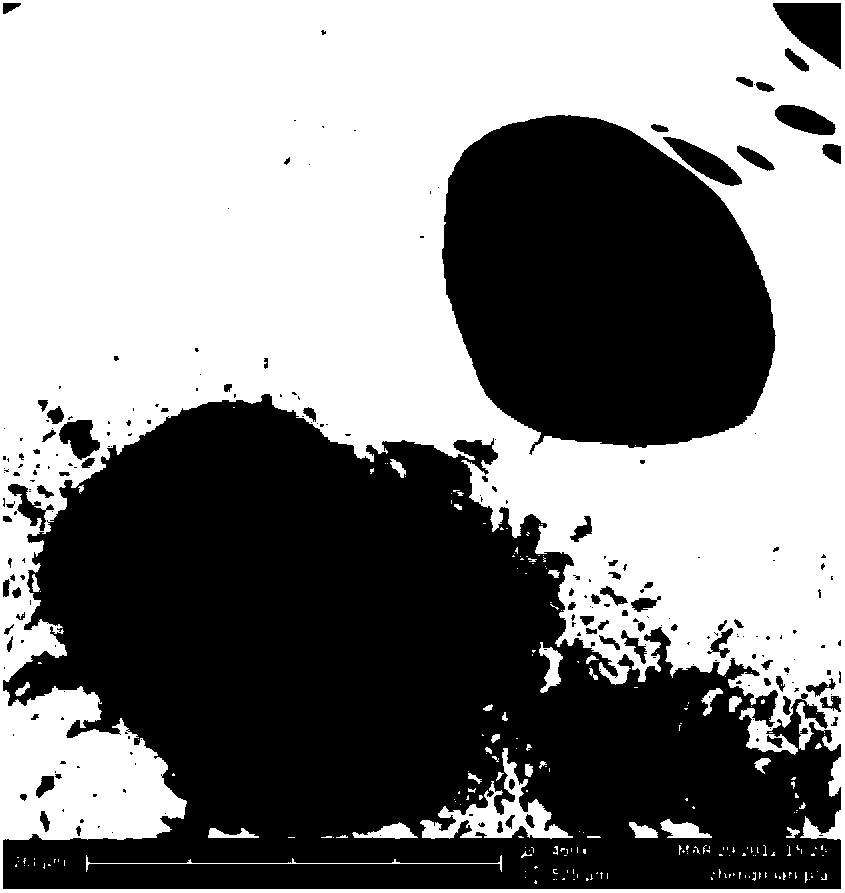

[0045] The oil-water separation omentum obtained in the above 1 was scanned with an electron microscope, and the surface morphology was observed at a magnification of 9900 times. The results are as follows figure 1 As shown, it can be seen that there is a micro-nano composite porous structure, which can be observed at 460 times magnification as figure 2 As shown, it can be seen that the omentum has a macroporous structure of 50nm-300um under the action of sodium chloride, the largest pore diameter can reach 300um, and the smallest pore diameter is only 50nm.

[0046] 2. Research on oil absorption and hydrophobicity of oil-water separation omentum

[0047] In the air, drop 2 microliters of water on the oil-water separation membrane obtained in the above 1, and use a contact angle measuring instrument, the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com