Dendrite silver phosphate visible light catalyst and preparation method thereof

A catalyst and visible light technology, applied in the field of photocatalysis, can solve the problems of few preparation methods, difficult control of morphology and performance, and achieve the effects of simple process, excellent photocatalytic performance and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method step of dendritic silver phosphate visible light catalyst of the present invention is as follows:

[0028] Weigh a certain amount of AgAc respectively, place them in beakers and dissolve them with deionized water respectively, and prepare AgAc solutions with a concentration of 0.03M-0.3M. Prepare 6 mL of sodium deoxycholate with a concentration of 0.036M-0.36M, and slowly inject sodium deoxycholate into the completely dissolved AgAc solution under the condition of magnetic stirring (30 ml of AgAc solution with a concentration of 0.3M, add 0.36M concentration of deoxygenated Sodium cholate (6 ml) was magnetically stirred at room temperature for 2 h. Add 4mL of distilled water to the above solution, add 1-10 drops of 85wt% phosphoric acid, and magnetically stir for 1 hour to obtain a precipitate. The precipitate was collected by centrifugation, washed three times with deionized water and ethanol, and then dried at 60°C. That is, a dendritic silver...

Embodiment 1

[0033] Weigh the AgAc, put it in a beaker and dissolve it with deionized water respectively to prepare 30mL AgAc solution with a concentration of 0.03M. Prepare 6 mL of 0.036M sodium deoxycholate, slowly inject it into the completely dissolved AgAc solution under the condition of magnetic stirring, and magnetically stir for 2 hours at room temperature. Add 4 mL of distilled water to the above solution, add 1 drop of 85 wt% phosphoric acid, and stir magnetically for 1 h. The precipitate was collected by centrifugation, washed several times with deionized water and alcohol, and dried at 60°C to obtain a sample.

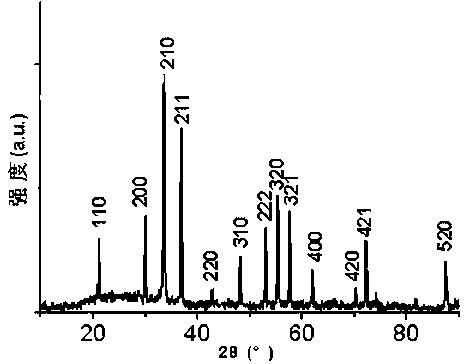

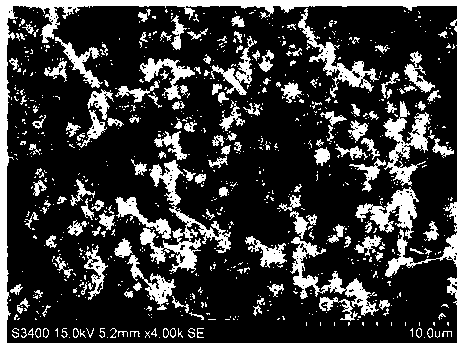

[0034] figure 1 For the X-ray diffraction pattern of obtained sample, the diffraction peaks of all samples are consistent with simple cubic crystal Ag 3 PO 4 The standard map (JCPDS No. 06-0505) corresponds exactly. Moreover, there are no diffraction peaks of other crystals in the diffraction pattern, indicating that the prepared material is pure Ag 3 PO 4 crystal...

Embodiment 2

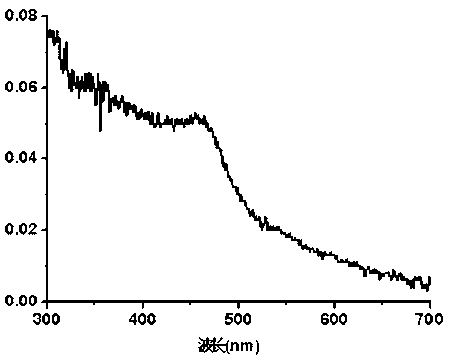

[0038] Visible light catalytic performance evaluation of dendritic silver phosphate prepared by the method of the present invention.

[0039] The visible light catalytic performance of the dendritic silver phosphate prepared by the method of the invention is evaluated by using samples to degrade organic matter under simulated visible light. The photocatalytic experiment was carried out in a photochemical reactor (including Xe lamp 350W, optical filter, magnetic stirrer). Weigh 0.05g of prepared sample, add liquid dye solution (10 -5 M RhB (rhodamine B), 30mg / L MO (methyl orange)), magnetically stirred for 30min under dark conditions to reach adsorption-desorption equilibrium. A 350W Xe lamp plus a filter (λ>420nm) was used as a simulated light source, and 3ml of the suspension was taken at regular intervals, and the supernatant was taken after centrifugation (6000rpm, 5min). The absorbance of the dye solution was measured using a UV-2550 ultraviolet-visible spectromete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com