Preparation method for cobalt carbonate material with dense structure and globoid shape

A sphere-like, cobalt carbonate technology, applied in cobalt carbonate and other directions, can solve the problems of disordered morphology, loose microstructure of cobalt carbonate materials, poor uniformity, etc., and achieve better structure compactness, easy control of process parameters, and better particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put the filtered cobalt chloride solution with a cobalt concentration of 1.0 mol / L and a pH value of 4.75 into the reactor;

[0024] Under stirring conditions, the heating step Solution, control the temperature of the solution system at 55°C, and keep the temperature of the system relatively stable;

[0025] Spray the pre-filtered ammonium bicarbonate solution with a concentration of 1.8 mol / L to the step at a constant speed of 800L / h in the system;

[0026] control step The pH value of the medium solution system is 7.5 as the end point of the system reaction, that is, the addition of the ammonium bicarbonate solution is terminated;

[0027] will step The obtained solid-liquid system was aged for 20 minutes, filtered and washed repeatedly to obtain the desired material.

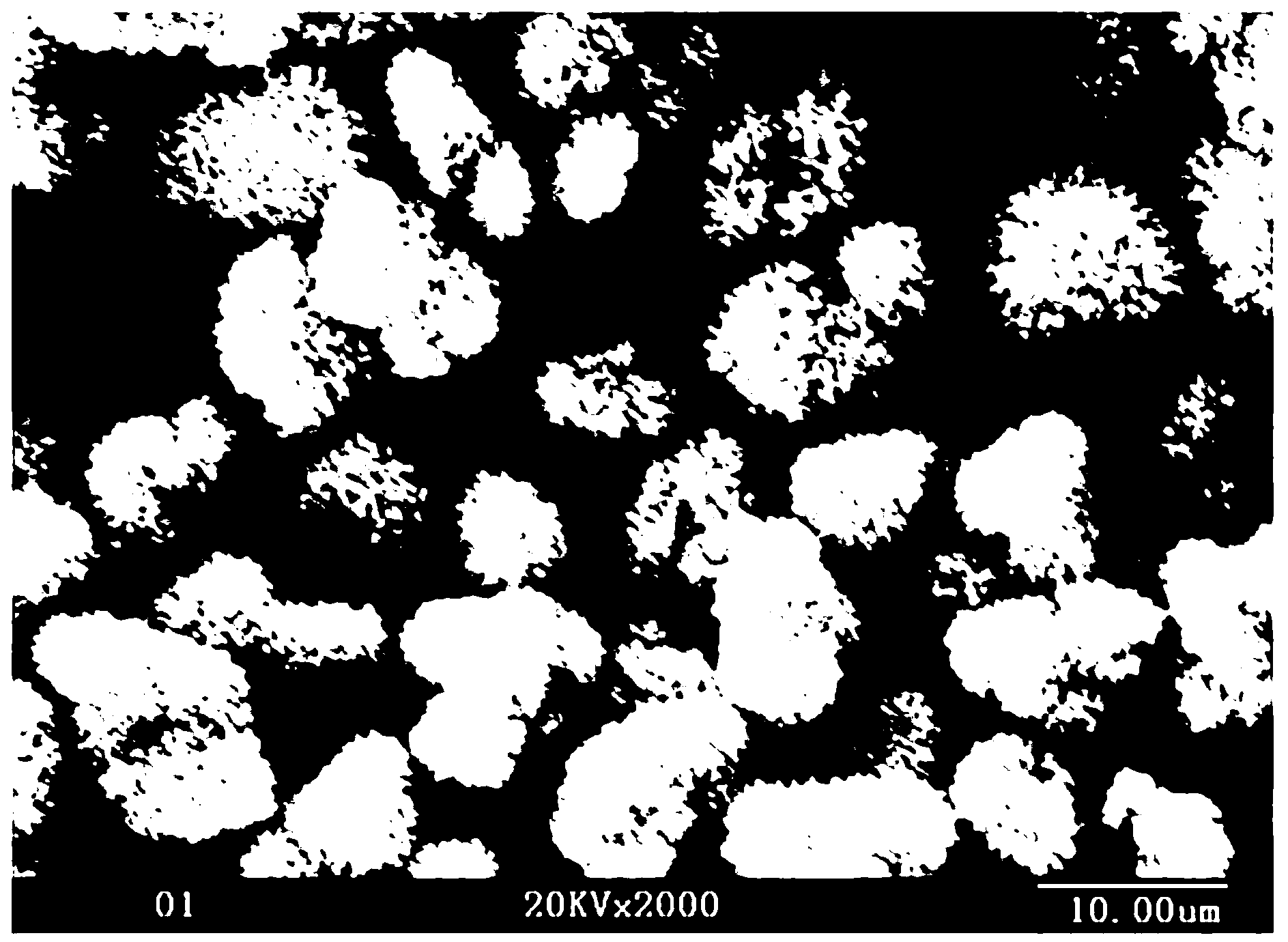

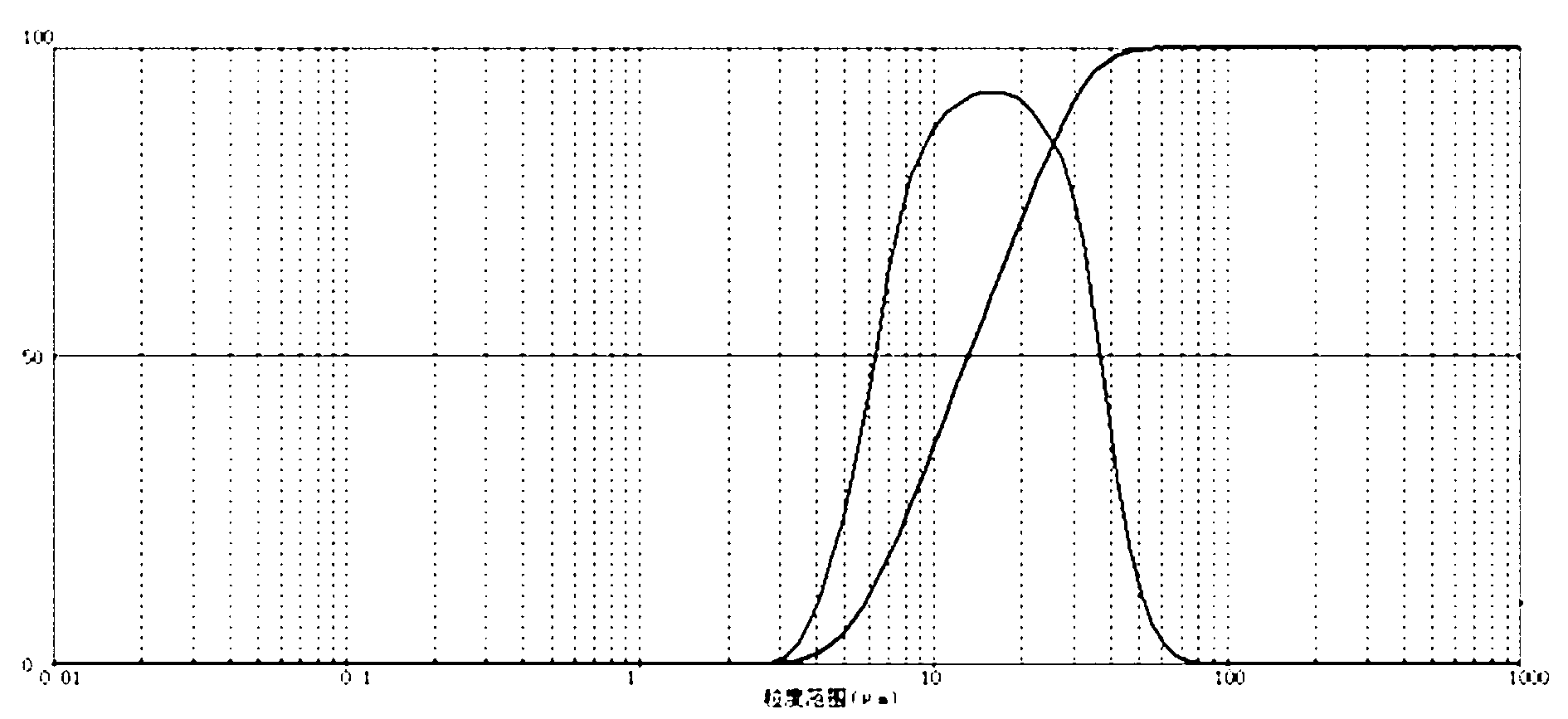

[0028] The spherical shape structure and particle size distribution of the material obtained in embodiment 1 are as follows: figure 1 and figure 2 , the physical index "particle s...

Embodiment 2

[0030] Put the filtered cobalt chloride solution with a cobalt concentration of 1.5 mol / L and a pH value of 4.80 into the reactor;

[0031] Under stirring conditions, the heating step Solution, control the temperature of the solution system at 63°C, and keep the temperature of the system relatively stable;

[0032] Spray the pre-filtered ammonium bicarbonate solution with a concentration of 2.0 mol / L to the step at a constant speed of 588L / h in the system;

[0033] control step The pH value of the middle solution system is 7.2 as the end point of the system reaction, that is, the addition of the ammonium bicarbonate solution is terminated;

[0034] will step The obtained solid-liquid system was aged for 30 minutes, filtered and washed repeatedly to obtain the desired material.

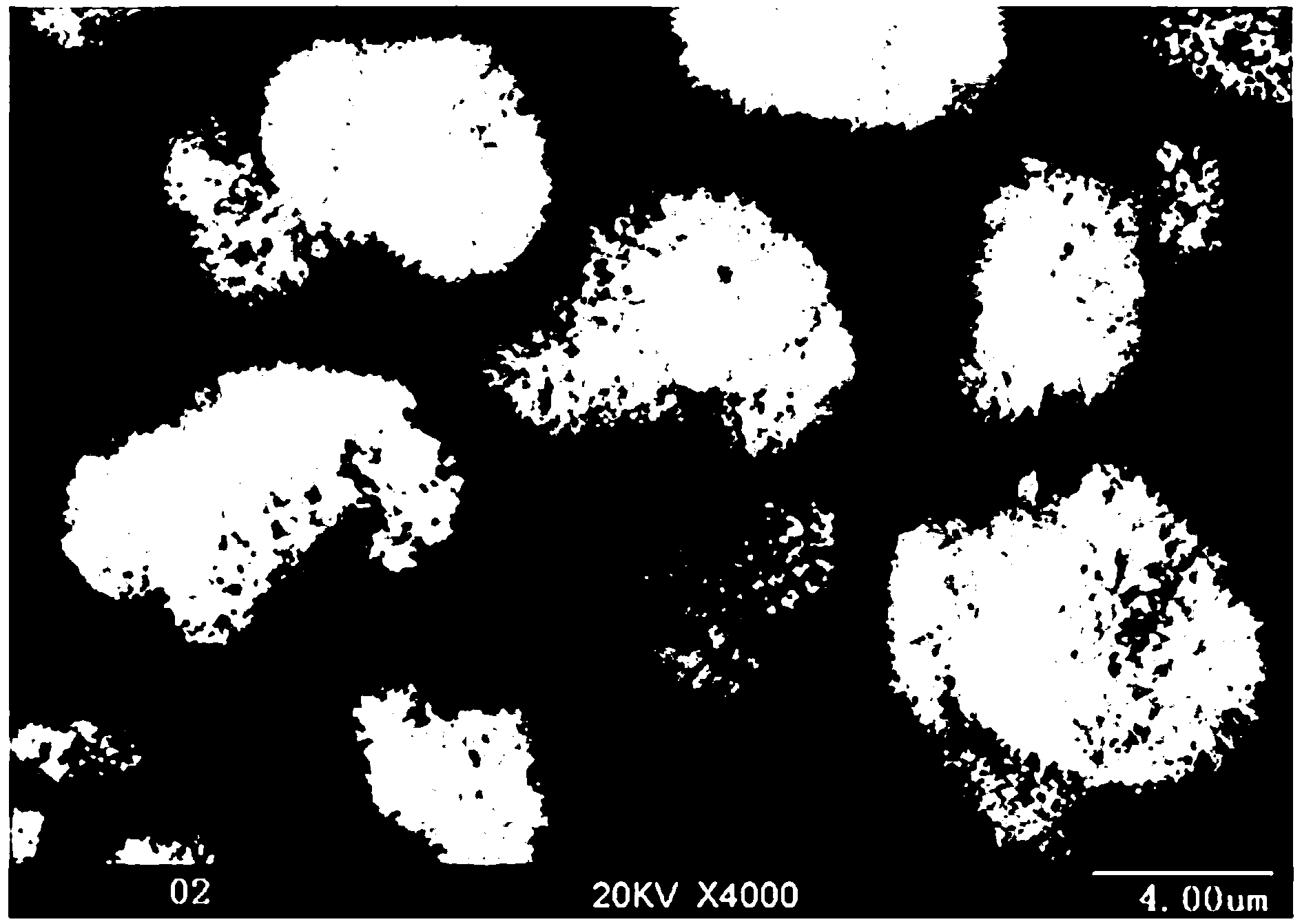

[0035] The spheroid morphology and particle size distribution of the material obtained in embodiment 2 are as follows: image 3 and Figure 4 , the physical index "particle size an...

Embodiment 3

[0037] Put the filtered cobalt chloride solution with a cobalt concentration of 1.6 mol / L and a pH value of 5.09 into the reactor;

[0038] Under stirring conditions, the heating step Solution, control the temperature of the solution system at 60°C, and keep the temperature of the system relatively stable;

[0039] Spray the pre-filtered ammonium bicarbonate solution with a concentration of 1.86 mol / L to the step at a constant speed of 280L / h in the system;

[0040] control step The pH value of the middle solution system is 7.2 as the end point of the system reaction, that is, the addition of the ammonium bicarbonate solution is terminated;

[0041] will step The obtained solid-liquid system was aged for 30 minutes, filtered and washed repeatedly to obtain the desired material.

[0042] The spheroid morphology and particle size distribution of the material obtained in embodiment 3 are as follows: Figure 5 and Figure 6 , the physical index "particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com