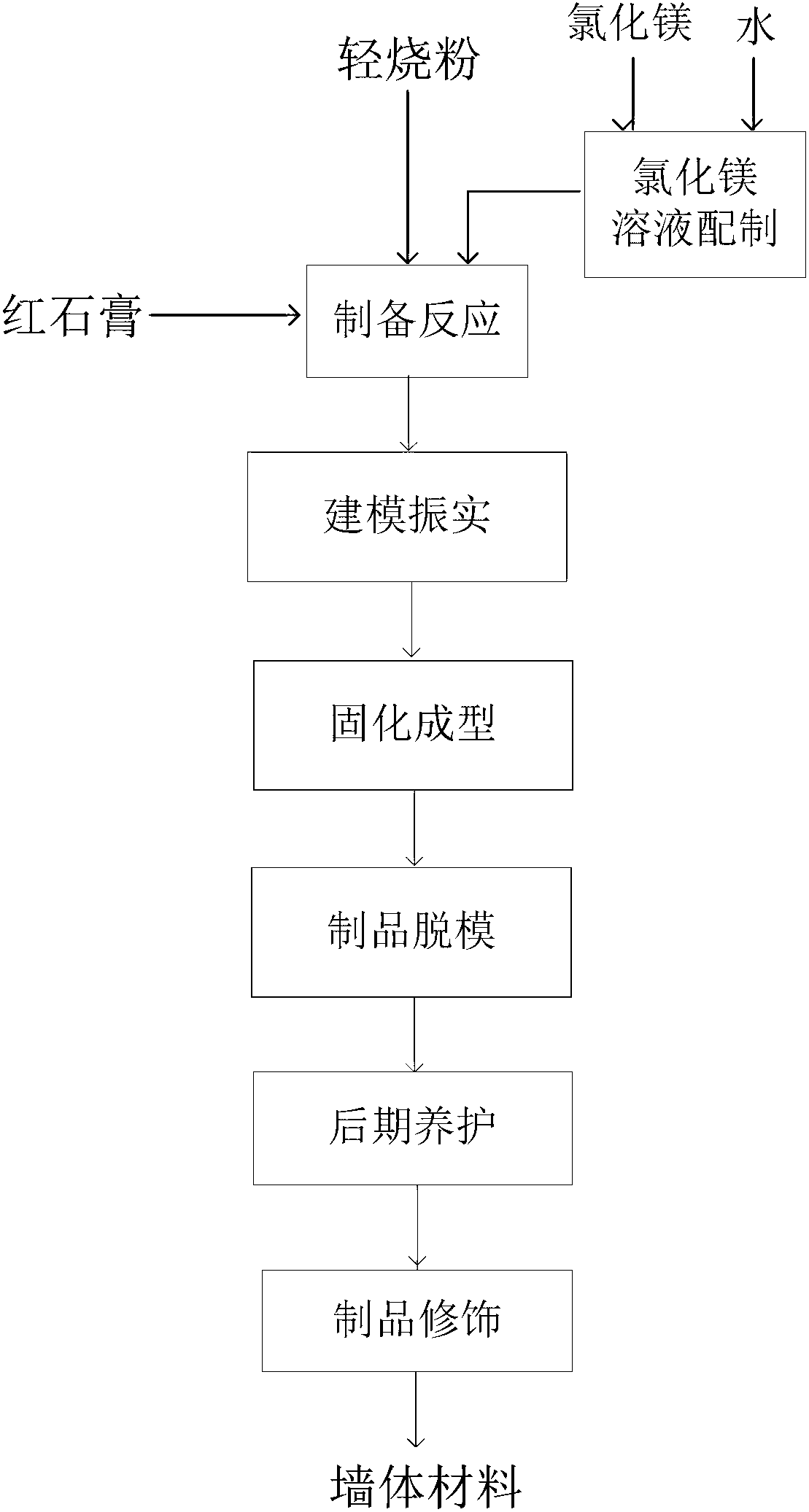

Resource utilization method for red gypsum produced by means of sulfuric acid process of titanium dioxide factory

A titanium dioxide factory and red gypsum technology, which is applied in the field of red gypsum resource utilization, can solve the problems of white spots on the surface of products, large heat release, too fast condensation, etc., and achieves simple and easy technology and equipment flow, and low requirements for equipment materials. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

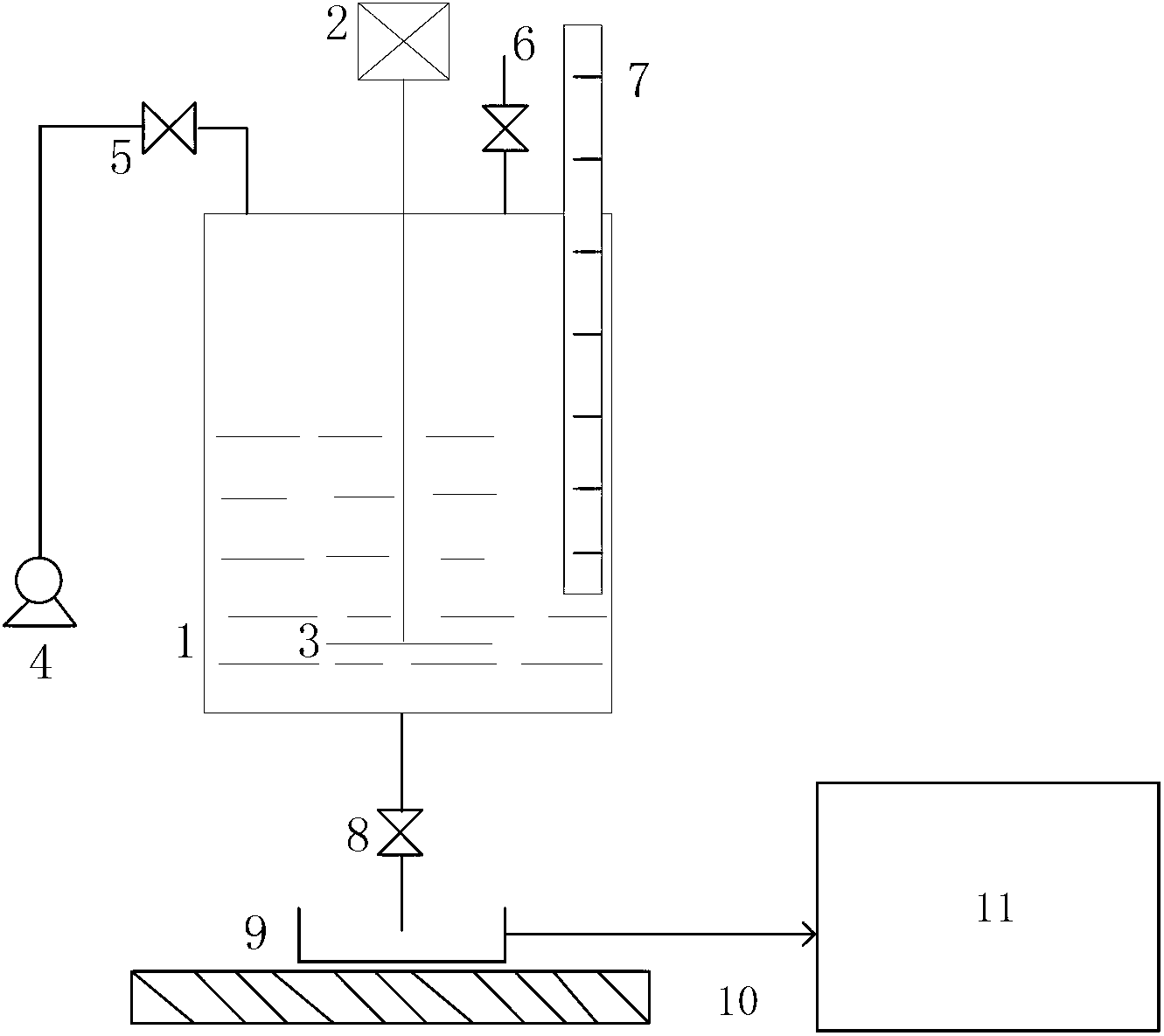

Method used

Image

Examples

Embodiment 1

[0049] Experimental ingredients: Liaoning Haicheng magnesite light-burned powder (passed through a 150-mesh sieve, the composition is shown in Table 2) 400g, red gypsum 560g (mass ratio to light-burned powder is 1.4), magnesium chloride hexahydrate 210g, water 120ml.

[0050] Experimental conditions: The molar ratio of magnesium oxide, magnesium chloride and water in magnesite lightly burned powder is 6.5:1:18, room temperature (about 25°C), stirring speed 150rpm, reaction time about 5-10min, using ISO cement mortar triplex For mold testing, the curing molding time is 24 hours, the curing time is 3 days, and the water resistance test time is 28 days.

[0051] Experimental results: According to the strength inspection standard of cement products, the flexural strength is 2.10Mpa and the compressive strength is 4.5Mpa. After the water resistance test, the flexural strength was determined to be 1.81Mpa, and the compressive strength was 3.87Mpa.

Embodiment 2

[0053] Experimental ingredients: Liaoning Haicheng magnesite light-burned powder (passed through a 150-mesh sieve, the composition is shown in Table 2) 400g, red gypsum 480g (mass ratio to light-burned powder is 1.2), magnesium chloride hexahydrate 210g, water 120ml.

[0054] Experimental conditions: The molar ratio of magnesium oxide, magnesium chloride and water in magnesite lightly burned powder is 6.5:1:18, room temperature (about 25°C), stirring speed 150rpm, reaction time about 5-10min, using ISO cement mortar triplex For mold testing, the curing molding time is 24 hours, the curing time is 3 days, and the water resistance test time is 28 days.

[0055] Experimental results: According to the strength inspection standard of cement products, the flexural strength is 3.90Mpa and the compressive strength is 13.7Mpa. After the water resistance test, the flexural strength was determined to be 3.52Mpa, and the compressive strength was 12.46Mpa.

Embodiment 3

[0057] Experimental ingredients: Liaoning Haicheng magnesite light-burned powder (passed through a 150-mesh sieve, the composition is shown in Table 2) 400g, red gypsum 400g (mass ratio to light-burned powder is 1.0), magnesium chloride hexahydrate 210g, water 120ml.

[0058] Experimental conditions: The molar ratio of magnesium oxide, magnesium chloride and water in magnesite lightly burned powder is 6.5:1:18, room temperature (about 25°C), stirring speed 150rpm, reaction time about 5-10min, using ISO cement mortar triplex For mold testing, the curing molding time is 24 hours, the curing time is 3 days, and the water resistance test time is 28 days.

[0059] Experimental results: According to the strength inspection standard of cement products, the flexural strength is 8.30Mpa and the compressive strength is 24.2Mpa. After the water resistance test, the flexural strength was determined to be 7.67Mpa, and the compressive strength was 22.38Mpa.

[0060] The wall material produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com