Hydrophobic mesoporous nanomaterial and preparation method and application thereof

A technology of nanomaterials and mesoporous materials, applied in the field of hydrophobic mesoporous nanomaterials and their preparation, mesoporous nanomaterials and their preparation, can solve the problems of incomplete understanding and difficulties in the mechanism of action, and achieve the enhancement of low-intensity ultrasonic waves The effect of cavitation effect intensity, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] 1) Preparation of ordered mesoporous material MCM-41

[0053] Add cetyltrimethylammonium bromide (CTAB) to 0.1-10mol / L NaOH aqueous solution, stir at 0-100°C until clear; add TEOS, stir evenly; conduct hydrothermal reaction at 25-200°C 1 ~48 hours; the molar ratio of raw materials added is: SiO 2 :NaOH:CTAB:H 2 O=1:(0.1~0.8):(0.1~0.6):(20~80); take out, filter, wash and dry to get the crude product PMCM; place the crude product PMCM in ethanol, then add 1mol / L Hydrochloric acid, the volume ratio of ethanol to hydrochloric acid is 100:1~10:1; after heating and refluxing for 1~24 hours, filter, wash, and dry to obtain a pore diameter of 2~50nm, a particle size of 20~800nm, and a specific surface area 100~2000m 2 / g of MCM-41 ordered mesoporous material.

[0054] 2) Preparation of ordered mesoporous material MCM-48

[0055] Add cetyltrimethylammonium bromide (CTAB) to 0.1-10mol / L NaOH aqueous solution, stir at 0-100°C until completely dissolved; add silica sol (SiO 2...

Embodiment 1

[0066] The pore diameter is 2nm, the particle size is 20nm, and the specific surface area is 1000m 2 / g of ordered mesoporous material MCM-41 was added to the reaction flask, then n-hexane was added to make it fully dispersed, then hexamethyldisilazane was added, and stirred at 25°C for 24h; ordered mesoporous material MCM-41 was mixed with The molar ratio of hexamethyldisilazane is 1:0.05; then it is washed with n-hexane and ethanol in sequence, and then dried at 30-200°C to obtain a hydrophobic mesoporous nanomaterial, denoted as HMSN.

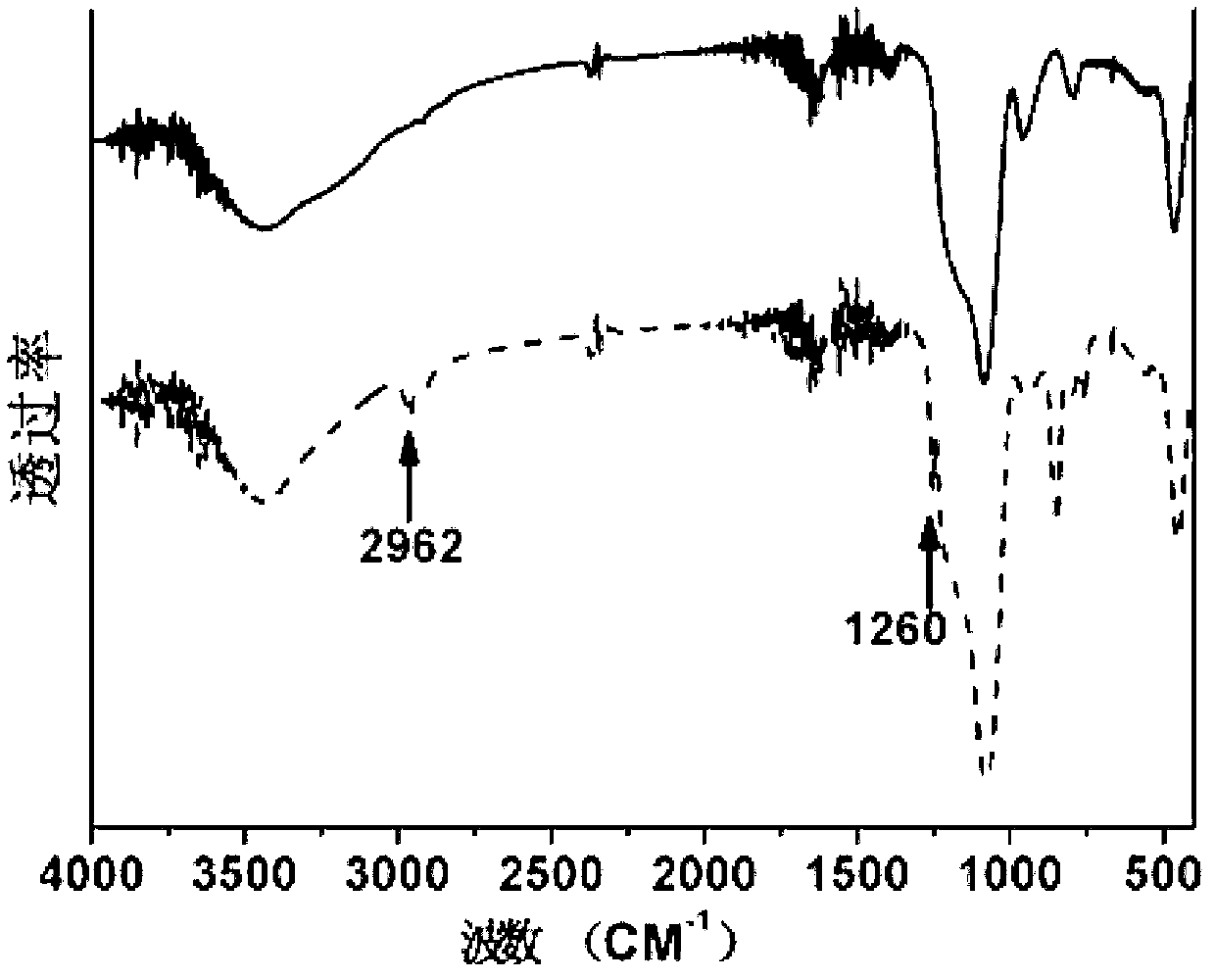

[0067] Depend on figure 1 It can be seen that at 2962cm -1 The existence of the C-H bond vibration peak at , indicates that the methyl group is grafted into the ordered mesoporous material MCM-41 through silane coupling.

[0068] Add the prepared hydrophobic mesoporous nanomaterials and β-CD into water at a mass ratio of 1:0.3, stir at 25°C for 24 hours, then wash with water and dry to obtain the solubilized hydrophobic mesoporous nanomate...

Embodiment 2

[0077] The pore diameter is 10nm, the particle size is 200nm, and the specific surface area is 100m 2 / g of ordered mesoporous material MCM-41 was added to the reaction flask, then n-hexane was added to make it fully dispersed, and then 1,3-divinyl-1,1,3,3-tetramethyldisilazane was added , stirred at 60°C for 12h; the molar ratio of ordered mesoporous material MCM-41 to 1,3-divinyl-1,1,3,3-tetramethyldisilazane was 1:0.09; Wash with alkanes and ethanol in sequence, and then dry at 30-200°C to obtain hydrophobic mesoporous nanomaterials, denoted as HMSN.

[0078] Depend on Figure 6 It can be known that the pore diameter of the prepared hydrophobic mesoporous nanomaterial is 2.3nm; by Figure 7 It can be known that the specific surface area of the prepared hydrophobic mesoporous nanomaterial is 1142m 2 / g; by Figure 8 It can be seen that the prepared hydrophobic mesoporous nanomaterials have a clear and uniform mesoporous structure; the measurement shows that the contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com