Polyethylene glycol-modified halloysite carbon nanotubes and preparation method thereof

A technology of halloysite nanotube and polyethylene glycol modification, which is applied in the treatment of dyed polymer organic compounds and fibrous fillers, etc., can solve the problems of affecting the application effect, unsatisfactory dispersion effect, and matrix agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

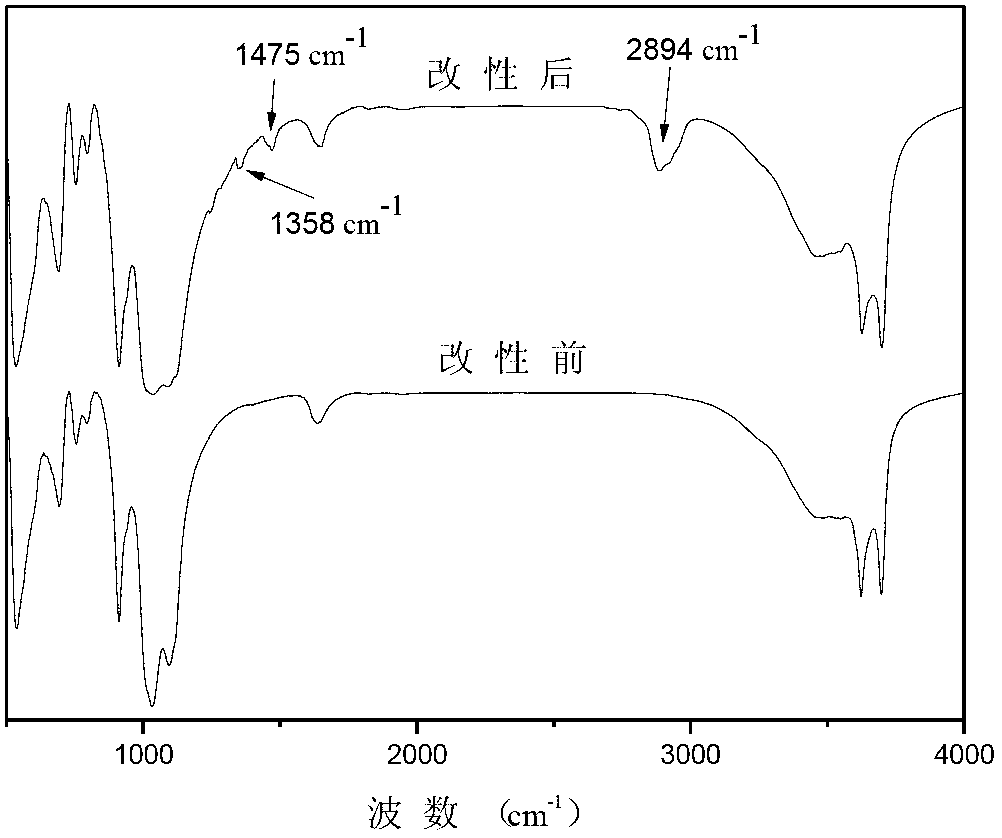

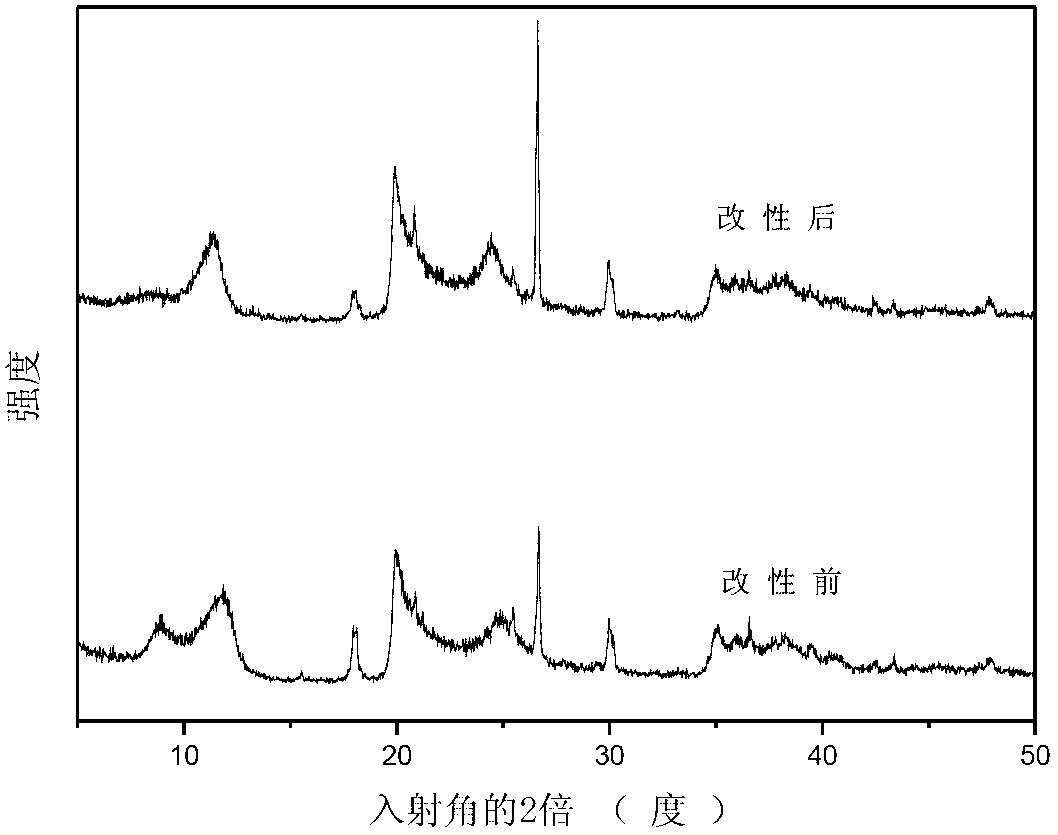

[0014] Prepare halloysite nanotubes and absolute ethanol into a suspension according to the mass ratio of 1:20, stir for 50 minutes and then ultrasonically disperse for 30 minutes until a uniform suspension is formed; filter the obtained suspension , take the upper solid and dry it in an oven at 60°C until the quality does not change, and then sieve it with a 200-mesh sieve to obtain impurity-free halloysite nanotubes. The purified halloysite nanotubes were added into deionized water at a mass ratio of 1:20, and ultrasonically dispersed until a uniform suspension was formed. Add polyethylene glycol to the suspension, and control the quality of the added polyethylene glycol to be 30% of the suspension mass. Stir at 60°C for 4 hours and then filter, dry the obtained solid at 60°C until there is no change in quality, grind it into powder, and sieve it with a 200-mesh sieve to obtain the modified halloysite nanotubes. The halloysite nanotube after the modified treatment of gained...

Embodiment 2

[0016] Prepare halloysite nanotubes and absolute ethanol into a suspension according to the mass ratio of 1:25, stir for 60 minutes and then ultrasonically disperse for 40 minutes until a uniform suspension is formed; filter the obtained suspension , take the upper solid and dry it in an oven at 65°C until the quality does not change, and then sieve it with a 250-mesh sieve to obtain impurity-free halloysite nanotubes. The purified halloysite nanotubes were added into deionized water at a mass ratio of 1:25, and ultrasonically dispersed until a uniform suspension was formed. Add polyethylene glycol to the suspension, and control the quality of the added polyethylene glycol to be 35% of the suspension mass. Stir at 65°C for 4.5h and then filter, dry the obtained solid at 65°C until there is no change in quality, grind it into powder, and sieve it with a 250-mesh sieve to obtain the modified halloysite nanotubes. The halloysite nanotube after the modified treatment of gained is...

Embodiment 3

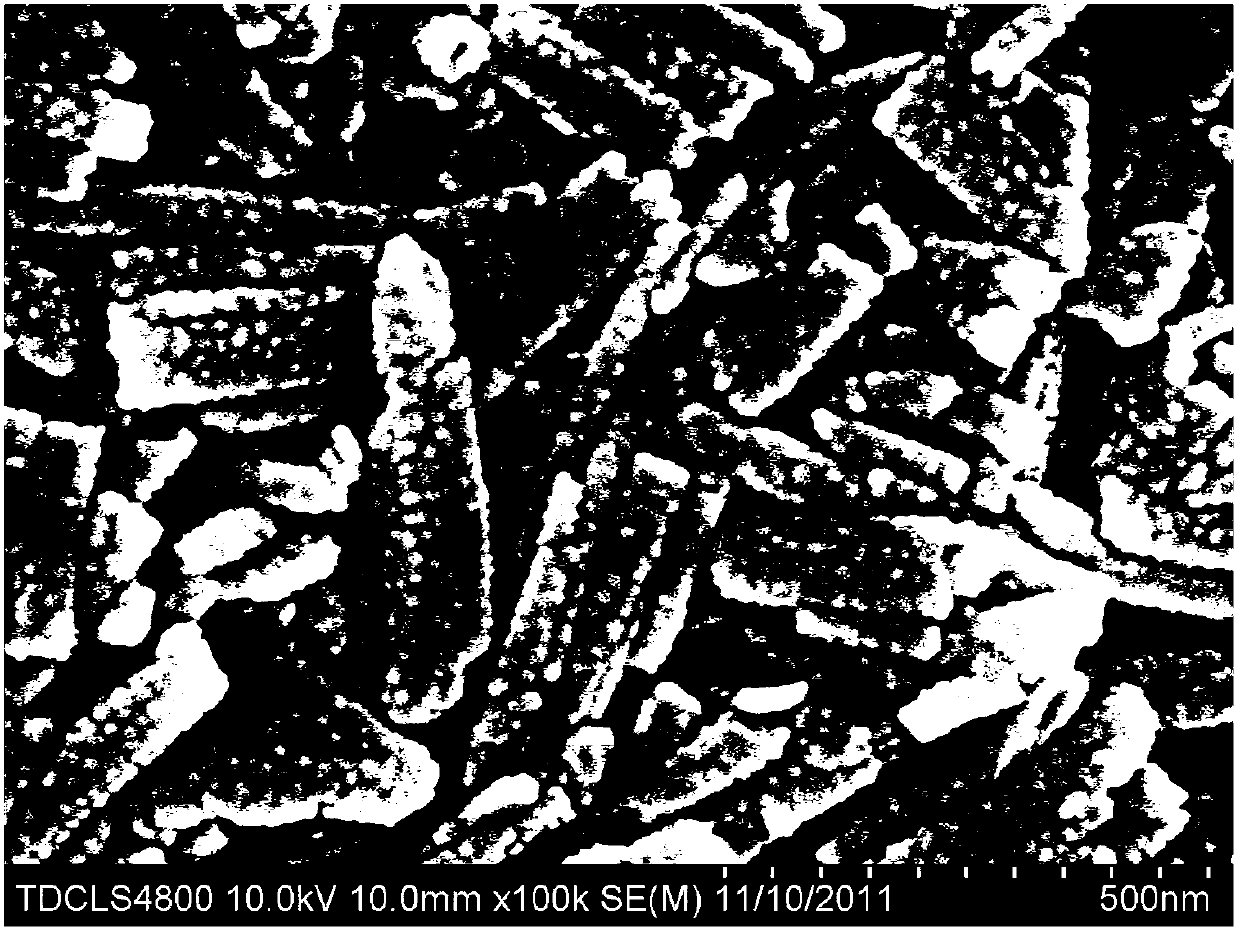

[0018] Prepare halloysite nanotubes and absolute ethanol into a suspension according to the mass ratio of 1:22, stir for 55 minutes and then ultrasonically disperse for 35 minutes until a uniform suspension is formed; filter the obtained suspension , take the upper solid and dry it in an oven at 63°C until the quality does not change, and then sieve it with a 230-mesh sieve to obtain impurity-free halloysite nanotubes. The purified halloysite nanotubes were added into deionized water at a mass ratio of 1:22, and ultrasonically dispersed until a uniform suspension was formed. Add polyethylene glycol to the suspension, and control the quality of the added polyethylene glycol to be 33% of the suspension mass. Stir at 63°C for 4.25h and then filter, dry the obtained solid at 63°C until there is no change in quality, grind it into powder, and sieve it with a 230-mesh sieve to obtain the modified halloysite nanotubes. The modified halloysite nanotubes were observed by scanning elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com