Preparation method of Al-Ti-B-C quaternary grain refiner

A grain refiner, al-ti-b-c technology, applied in the preparation of grain refiner, Al-Ti-B-C quaternary grain refiner, can solve the problem of increasing aluminum melt Wettability with boron carbide, lower reaction temperature, shorten preparation time of refiner, etc., to achieve the effect of shortening response time of refinement, lowering reaction temperature and shortening reaction preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

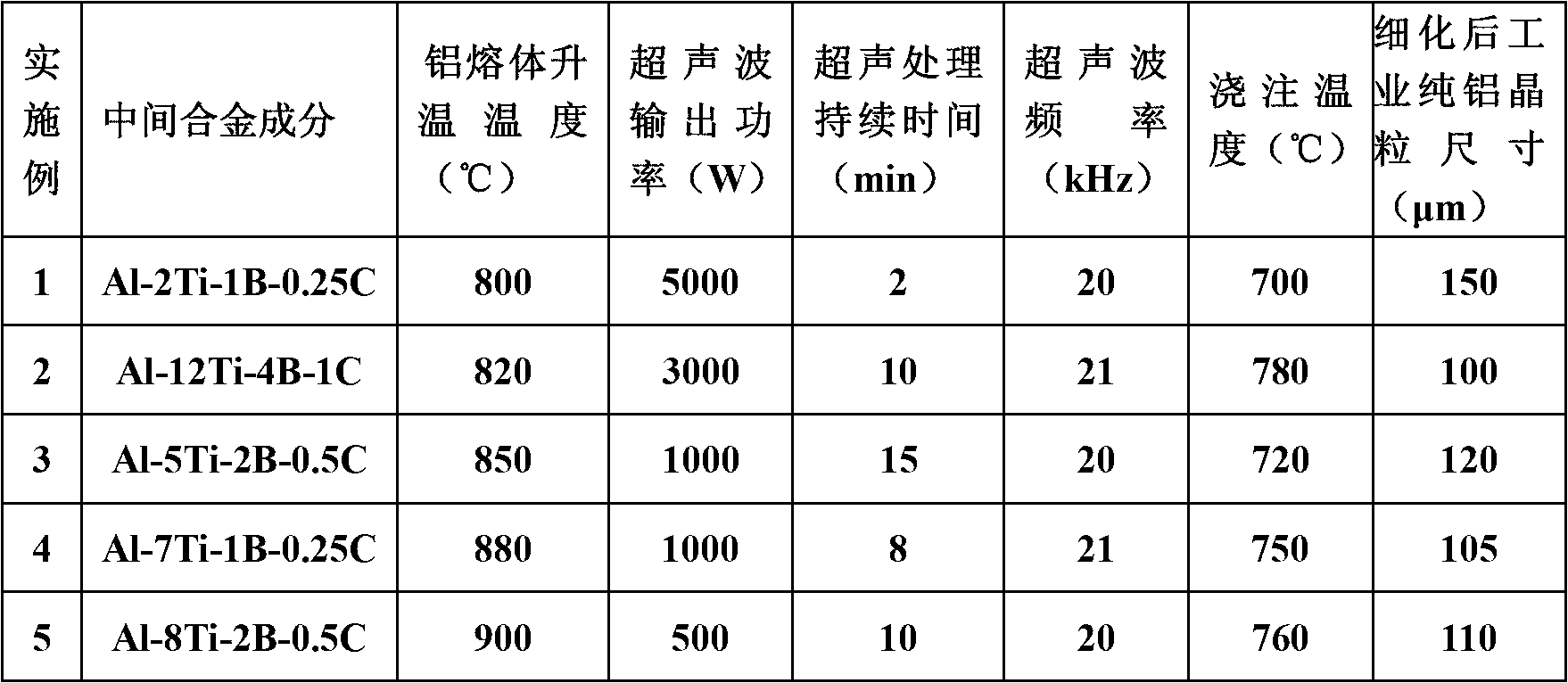

Embodiment 1-5

[0021] (1) According to the production weight percentage: 1.00-12.00% Ti, 1.00-4.00% B, 0.25-1.00% C, the balance is Al, weigh the sponge titanium, boron carbide powder and industrial pure aluminum, and mix the sponge titanium and carbonized Boron powder is evenly mixed;

[0022] (2) Heat up the temperature to 800°C-900°C to melt the weighed industrial pure aluminum in a resistance furnace;

[0023] (3) Press the prepared titanium sponge and boron carbide mixed powder into the aluminum melt using a graphite bell jar;

[0024] (4) Introduce ultrasonic waves with a frequency of 20±1kHz and a power of 500-5000W from the upper part of the melt, and continue the treatment for 1-15 minutes;

[0025] (5) Allow the melt to cool naturally, and when it is cooled to 700-780°C, cast it into an ingot-shaped Al-Ti-BC quaternary grain refiner.

[0026] Refining: 500 grams of industrial pure aluminum, heating and melting to 720 ° C, adding the prepared Al-Ti-BC quaternary grain refiner acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com